Lock pin

A technology of lock cylinders and movable parts, which is applied to building locks, locks controlled by non-mechanical transmission, buildings, etc., can solve problems such as incompatibility, difficulty, and large capacity of power supply systems, so as to improve reliability and service life, and drive The effect of small stroke and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

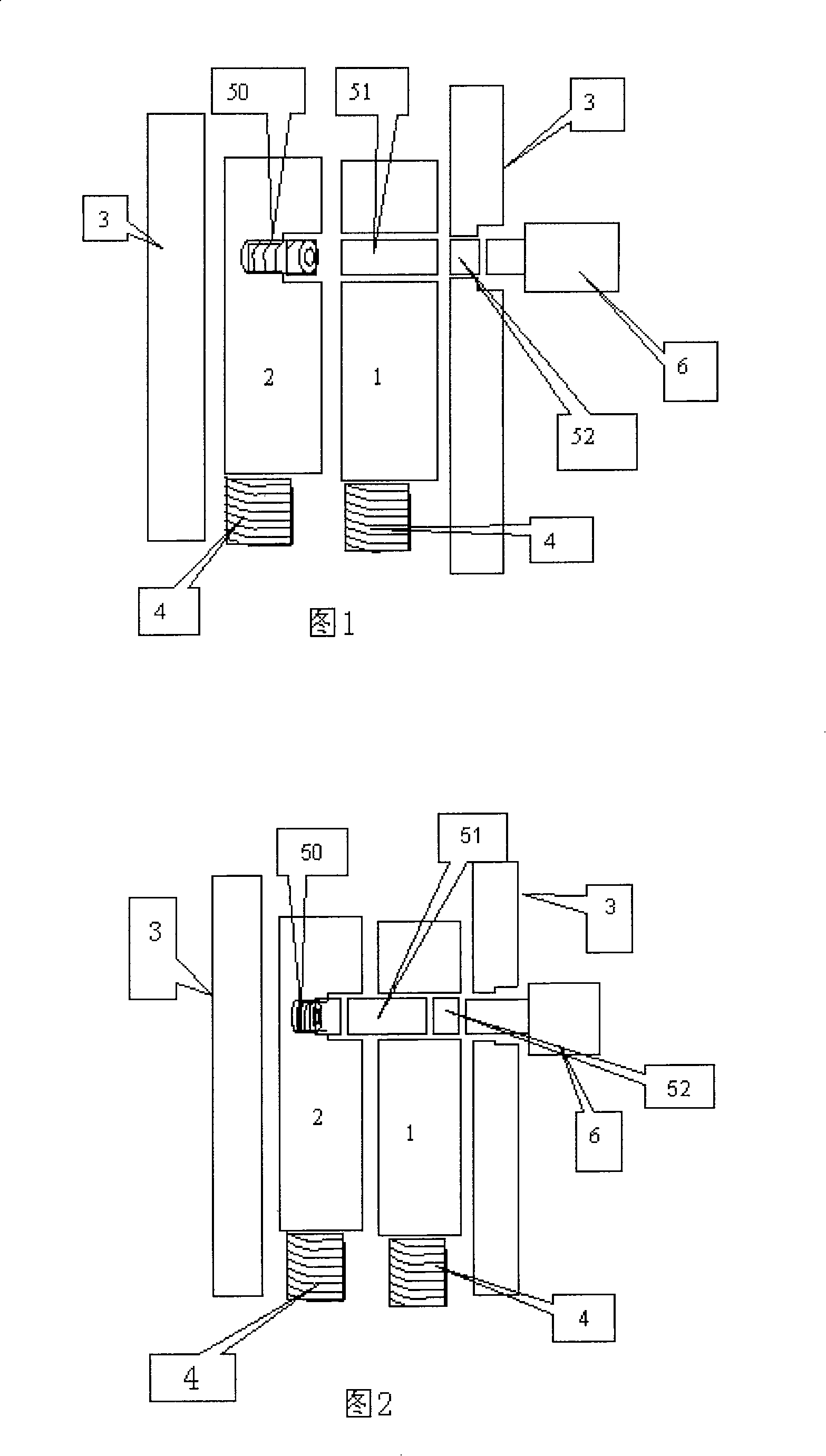

[0042] Embodiment 1: The first movable part 1 and the second movable part 2 are set side by side in the housing 3; the clutch part is composed of a first clutch pin 51 and a second clutch pin 52, and the guide hole is a blind hole; the bottom of the blind hole is located at The inner wall of the second movable part passes through the first movable part and opens to the casing, and a through hole is respectively formed on the first movable part and the casing; the elastic part is placed in the pin hole of the first movable part. As shown in Fig. 1 and Fig. 2, the separation and relative locking states of the first movable part 1 and the second movable part 2 are respectively, and the relative movement of the first movable part 1, the second movable part 2 and the housing 3 is shown in Fig. 1, The direction indicated by the arrow in Figure 2. Fig. 1 is a state where the elastic pin 50 is naturally stretched, and the first movable part 1, the second movable part 2, and the housin...

Embodiment 2

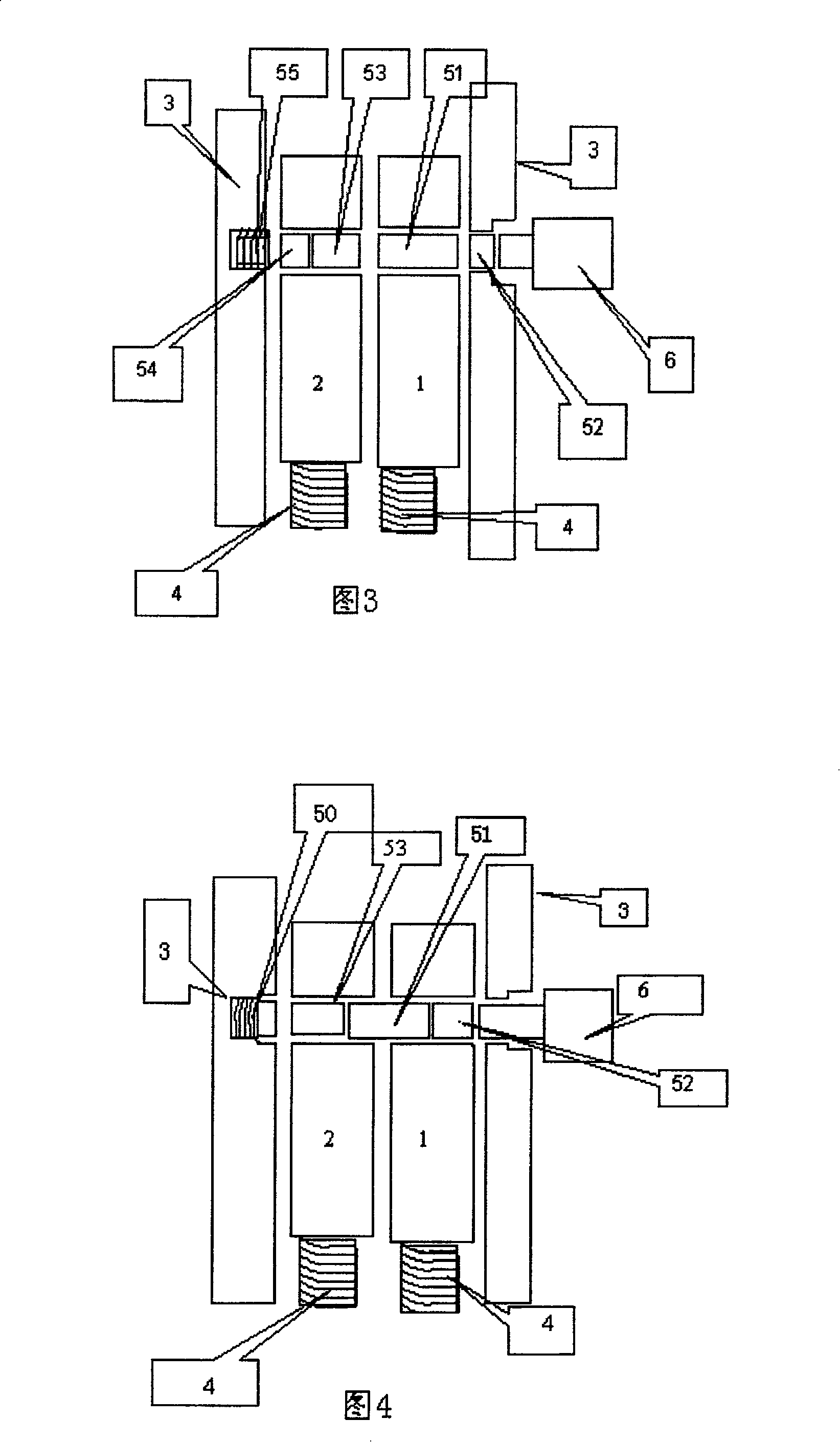

[0043] Embodiment 2: As shown in Figure 3 and Figure 4, it is a modification of Embodiment 1. The bottom of the blind hole is located on the side wall of the housing 3, passing through the first movable part 1 and the second movable part 2, and the opening is located at the side wall of the housing. On the other side wall, a through hole is respectively formed on the first movable part, the second movable part and the casing. The clutch includes a first clutch pin 51 , a second clutch pin 52 , a third clutch pin 53 , a fourth clutch pin 54 and a spring 55 . In the natural state, the first movable part 1, the second movable part 2, and the housing 3 are in a non-interfering and relatively independent state; the first clutch pin 51 is completely in the through hole of the first movable part, and its length is equal to that of the first movable part. Piece 1 thickness. The third clutch pin 53 and the fourth clutch pin 54 are completely in the through hole of the second movable p...

Embodiment 3

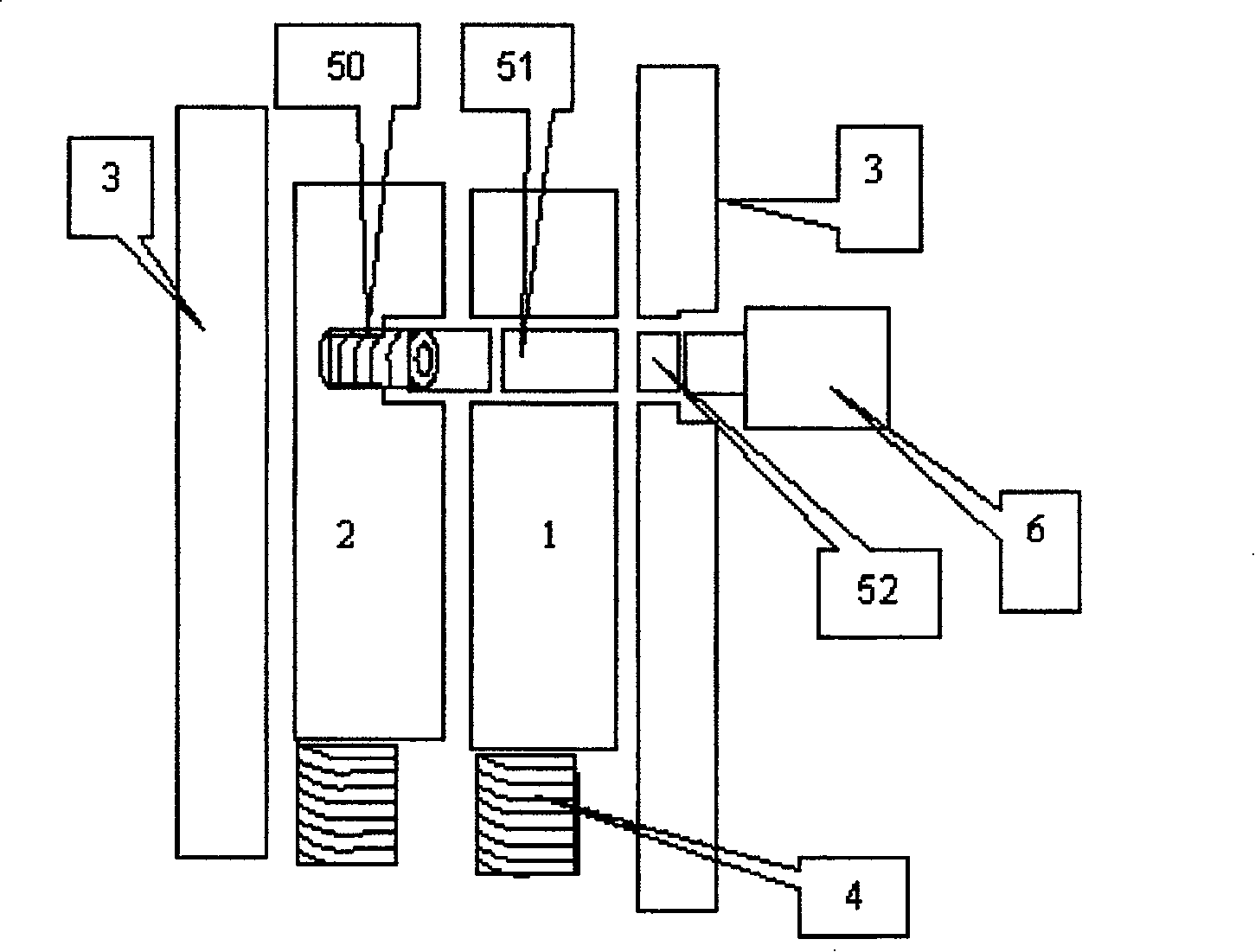

[0044] Embodiment three: as Figure 5 , Figure 6 as shown, Figure 5 When the elastic pin 50 is stretched naturally, the elastic pin 50 is located between the second movable part 2 and the first movable part 1 to lock the two with each other, and the two are in a freely movable state relative to the housing 3 . Figure 6 , the driving output shaft of the driving device 6 stretches out, drives the second clutch pin 52 into the through hole of the first movable part 1, and then presses the first clutch pin 51, and the first clutch pin 51 compresses the elastic pin 50, so that the first The movable part 1, the second movable part 2, and the housing 3 are in a state of being independent and freely movable. The length of the first clutch pin 51 plus the second clutch pin 52 is equal to the thickness of the first movable part 1 , and the length of the second clutch pin is equal to the axial displacement of the drive output shaft of the drive device 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com