Method for producing heat pipes

A manufacturing method and technology of heat pipes, which are applied in the field of heat pipe manufacturing, can solve problems such as the inability to dissipate heat from electronic components, the volume of heat pipes, and the reduction in volume of electronic components, and achieve the effects of small space occupation, small volume, and satisfying volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

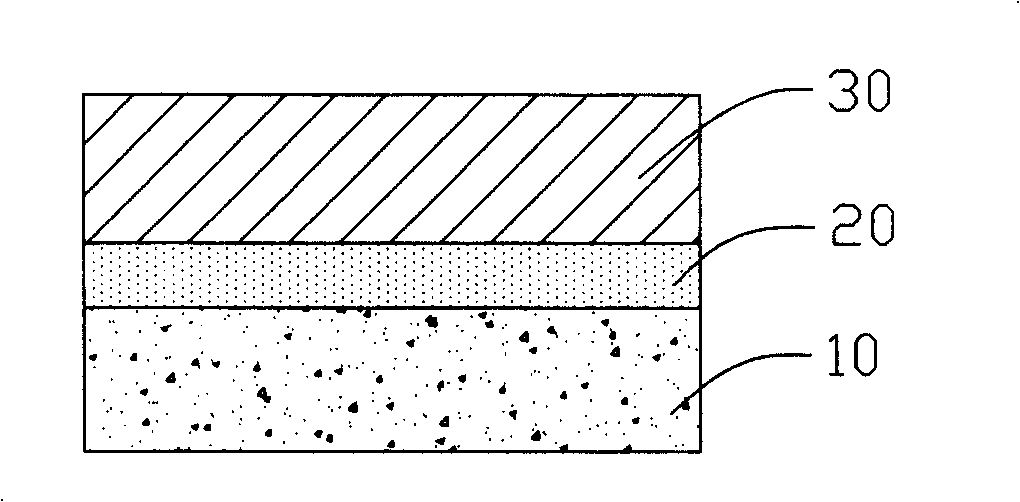

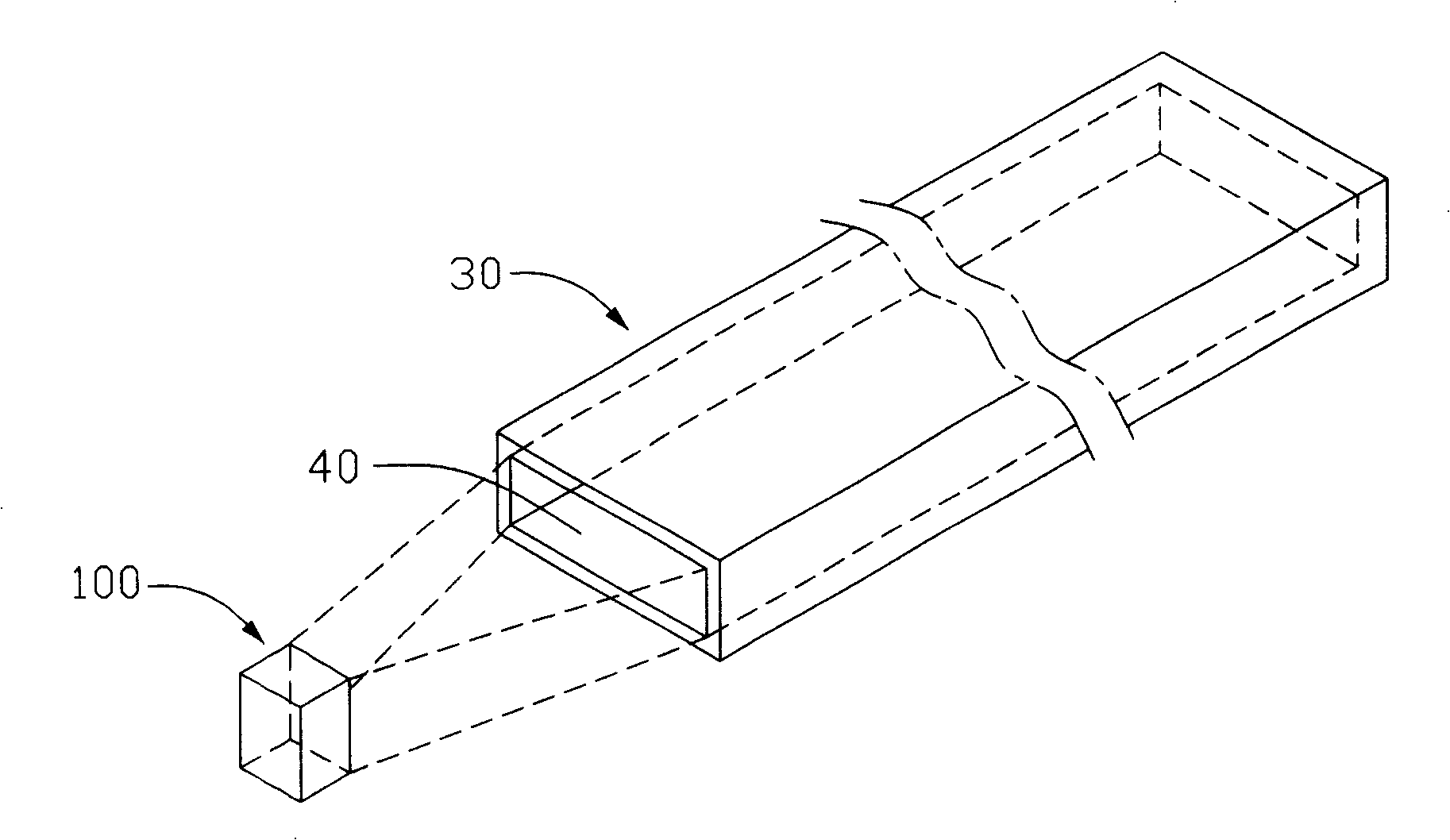

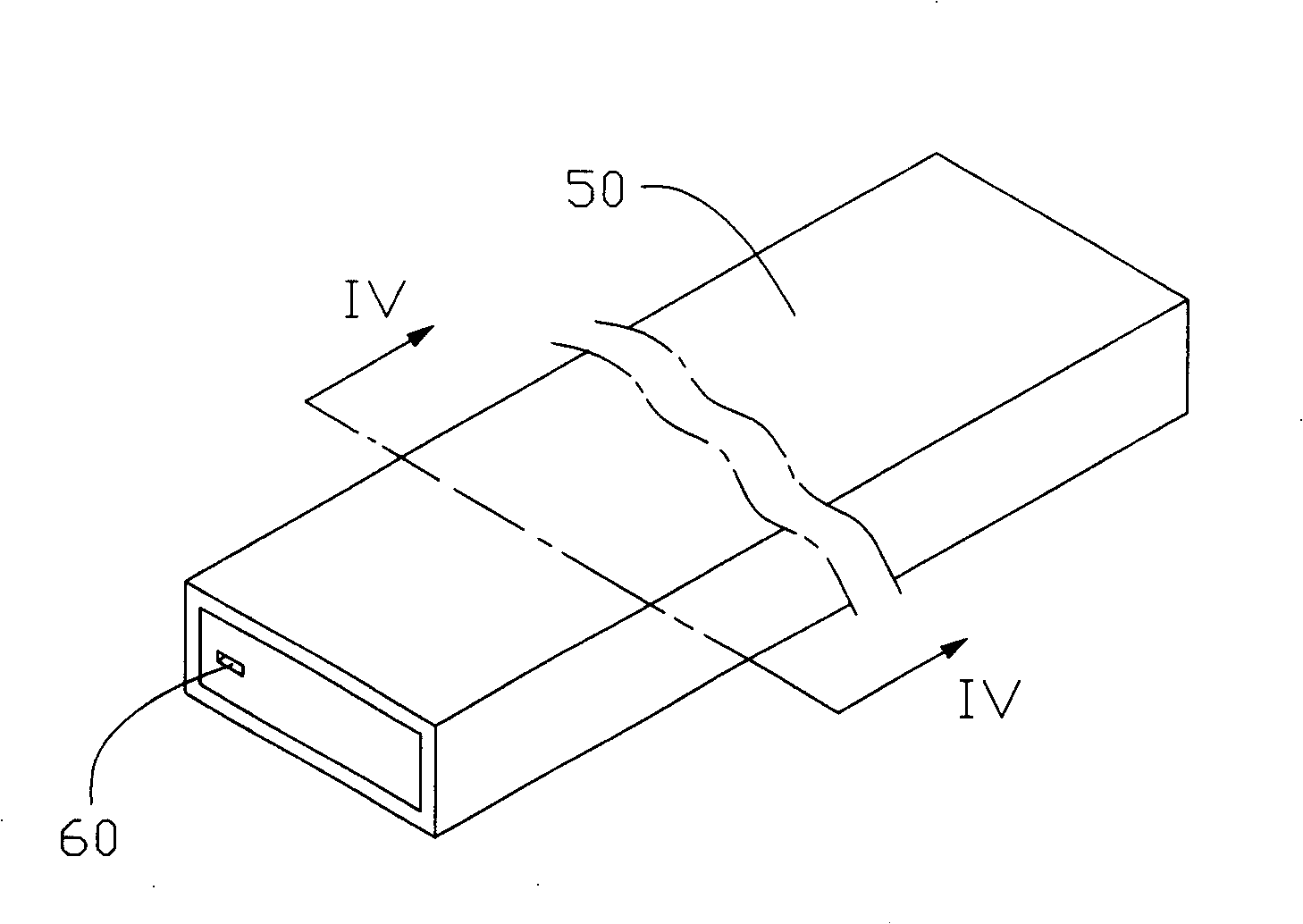

[0014] see Figure 1 to Figure 4 The heat pipe manufacturing method of the present invention is as follows: provide a substrate 10 (in the embodiment of the present invention, a silicon wafer is used as the substrate); and form a thin layer of silicon dioxide oxide layer 20 on the surface of the substrate 10 by dry oxidation. Place the above-mentioned substrate 10 with the oxide layer 20 attached on the surface on a vacuum coating machine, and apply an appropriate amount of photoresist attachment solution to evenly distribute it on the oxide layer 20 to form a photoresist layer 30 . After the coating is completed, place it on a heating plate for soft baking at a temperature of 90° C., so that the photoresist layer 30 changes from the original liquid state to a solid uniform film, so that the required photoresist layer 30 can be formed. Put the above-mentioned photoresist layer 30 on the stage of the exposure machine for exposure through the instrument 100, so as to transfer th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com