Circular, no-joint coated belt, and its prodn. tech.

A production process and jointless technology, which is applied to the surface coating liquid device, coating, layered products, etc., can solve the problem of poor tensile resistance and friction resistance of the coated strip, shortening the service life of the coated strip, and elongation and friction reduction, to achieve good setting effect, stable coating quality, and improve tensile and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

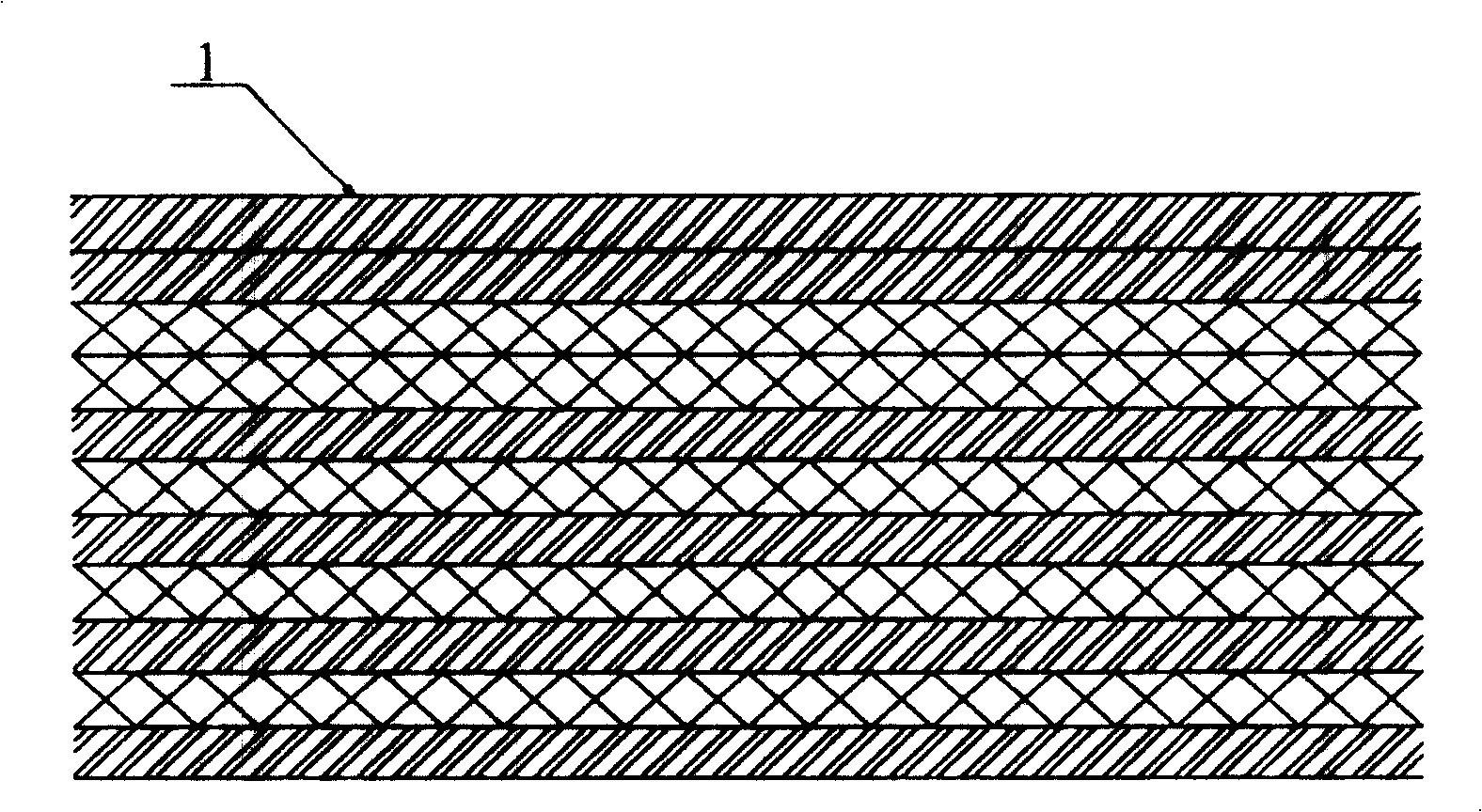

[0023] The endless jointless coated belt, including the belt body 1, has a structural feature that the belt body 1 has 11 layers from the outside to the inside, and the 1st to 7th layers are composed of 4 layers of synthetic fiber flakes and 3 layers of synthetic fiber base cloth. The 8th and 9th layers are all synthetic fiber base cloth layers, and the 10th and 11th layers are all synthetic fiber flake layers.

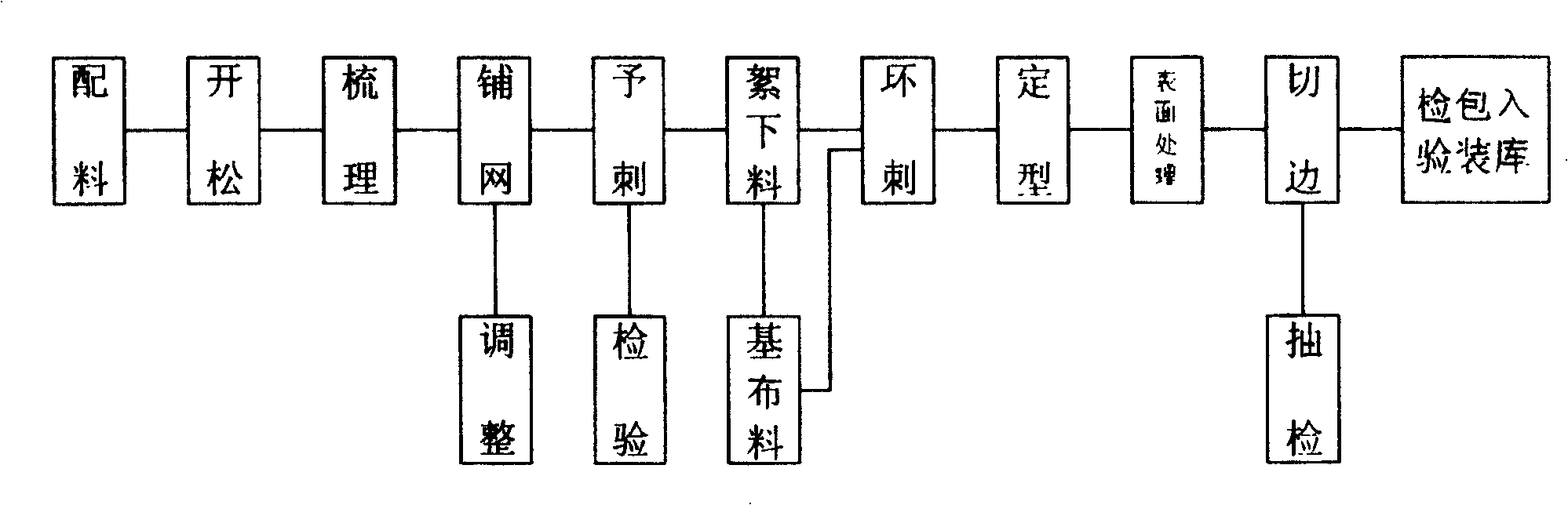

[0024] The production process of the endless coating belt includes the following process:

[0025] 1. Fiber ingredients: uniformly mix polyester fiber and viscose fiber into the opener, and the weight ratio of polyester fiber to viscose fiber is 2:1.

[0026] 2. Raw material opening: the mixed raw material enters into the opening machine for opening.

[0027] 3. Carding: The raw materials after opening go into the non-woven carding machine for carding.

[0028] 4. Laying: the carded fiber enters the laminating machine to lay the net.

[0029] 5. Pre-punching: After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com