Six-point supporting type hanging apparatus for vehicle double front axle

A suspension device and double front axle technology, applied to vehicle parts, suspensions, elastic suspensions, etc., can solve problems such as poor coordination of double front axles, uneven distribution of axle loads, large wheelbase of double front axles, etc., to achieve Movement coordination, compact and simple structure, the effect of attenuating impact vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

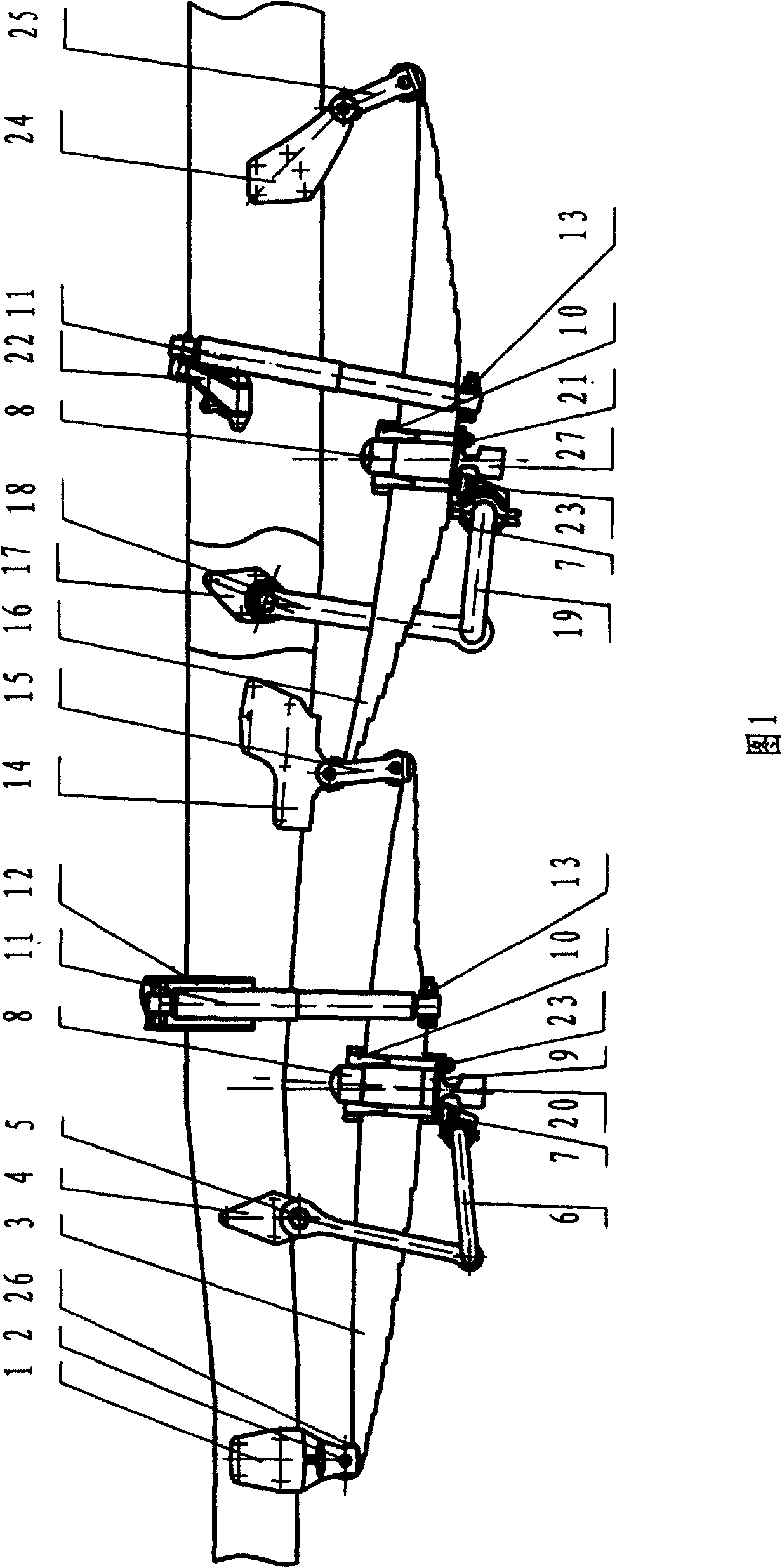

[0010] As shown in Figure 1, the present invention is made up of front support 1, bearing pin 2, the first front leaf spring 3, the first support 4, the first connecting rod 5, the first stabilizer bar 6, stabilizer bar support 7, Cover plate 8, first backing plate 9, bolt 10, damper 11, upper support 12, lower support 13, middle support 14, first lifting lug 15, second front leaf spring 16, second support 17, second support Second connecting rod 18, second stabilizer bar 19, first front axle 20, second backing plate 21, upper support 22, nut 23, rear support 24, second lifting lug 25, bolt 26, second front axle 27 Composition, which is characterized in that: double front axle six-point support device, through the front support 1, the middle support 14, the rear support 24, the first lifting lug 15, the second lifting lug 25, and the pin shaft 2, four The front leaf springs 3 and 16 are fixed on the vehicle frame, and the vehicle frame is equipped with a front support 1, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com