A composite insulator and method for producing same

一种复合绝缘子、生产方法的技术,应用在绝缘体、电气元件、电路等方向,能够解决伞裙的连接处易出现裂纹、瓷绝缘子耐污闪能力差、影响整体性能等问题,达到大实用和推广价值、性能可靠、结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

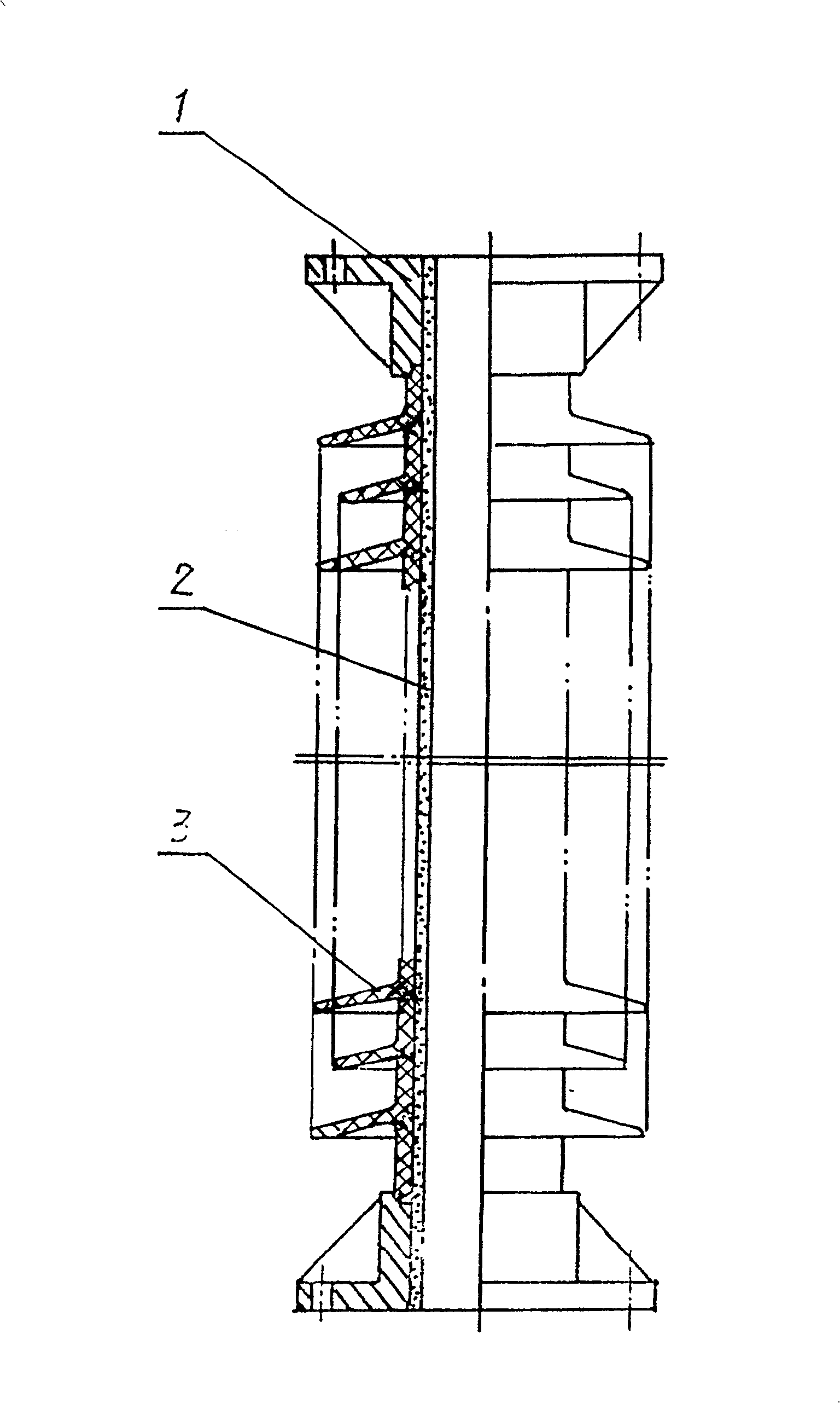

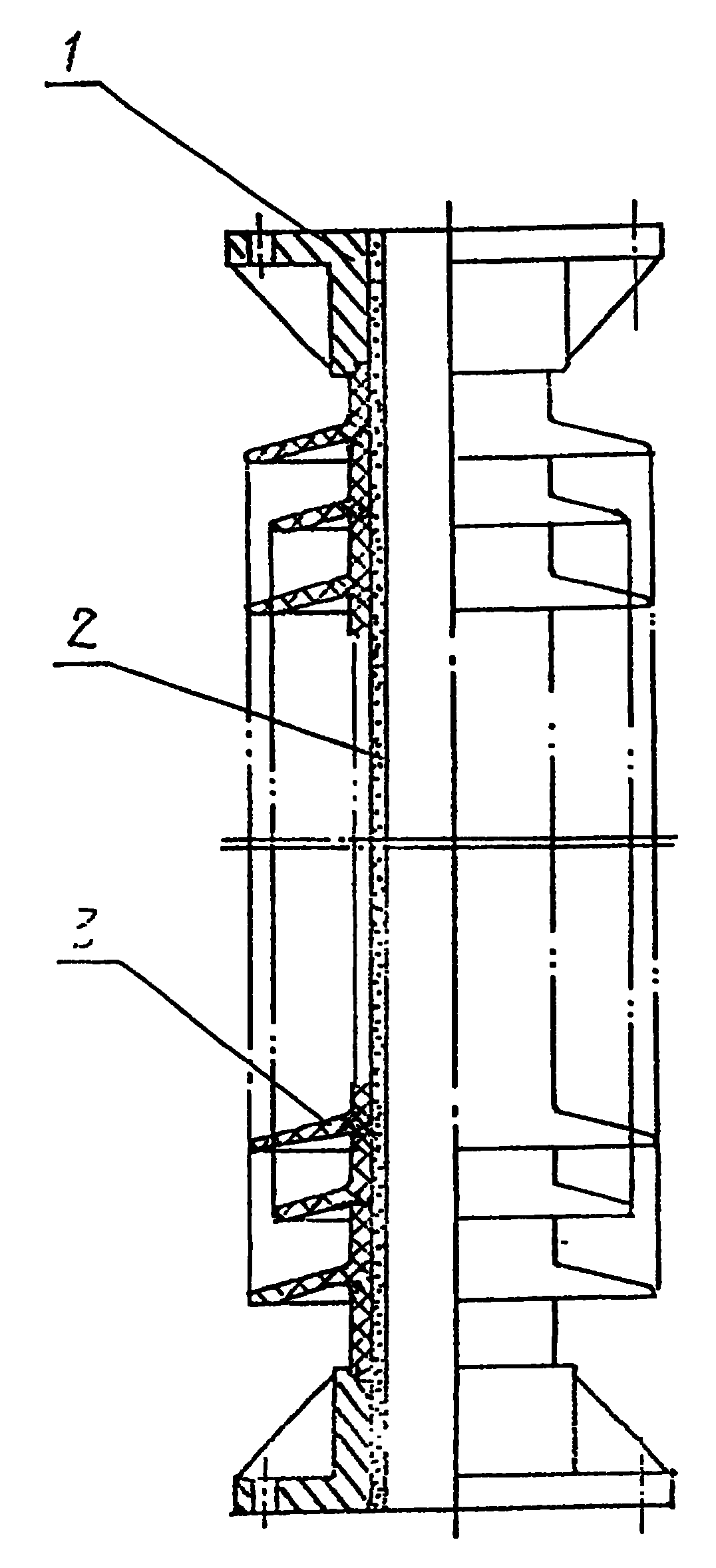

[0011] With reference to the accompanying drawings, the present invention is composed of a flange 1, an insulating cylinder 2, and an umbrella body 3. The insulating cylinder 2 is a hollow tube made by winding epoxy glass fibers. An integral umbrella body 3 is arranged outside the insulating cylinder 2. The body 3 is formed by injection of high-temperature vulcanized silicone rubber, and its heating temperature is 150°C-190°C, and the heating temperature in this embodiment is 155°C. The two ends of the insulating cylinder 2 are glued to the flange 1 with an adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com