Natural ª‰-carotene microcapsule and method for making same

A technology of carotene and microcapsules, which is applied in the field of natural β-carotene microcapsules and its preparation, can solve the problems of inability to produce high-content β-carotene powder, large loss of β-carotene, and increased process steps, etc., to achieve High embedding efficiency, high drying rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Put 100g of water into the container, slowly add 20g of modified starch under stirring state, stir well, let it stand overnight to make it dissolve. Add 40 g of 5% natural β-carotene oil, add 2 g of soybean lecithin and 0.2 g of TBHQ, heat the oil bath to 120° C. to dissolve it, and make the oil phase. Put 300g of water into the container, add 8g of maltodextrin, 16g of β-cyclodextrin, 1.5g of sorbitol fatty acid ester, 15g of maltose, and 0.5g of sodium benzoate, stir and heat to 80°C, and heat the spare modified starch solution to 70°C, added to the above solution to make the water phase. Add the oil phase to the water phase, keep the temperature at 80°C, and emulsify with an emulsifier at 4000 rpm for 20 minutes. Homogenize the emulsified liquid with a pressure of 40kg / cm 2 , the homogenized material is spray-dried at an inlet temperature of 195°C and an outlet temperature of 75°C to produce 2.1% natural beta-carotene microcapsules.

Embodiment 2

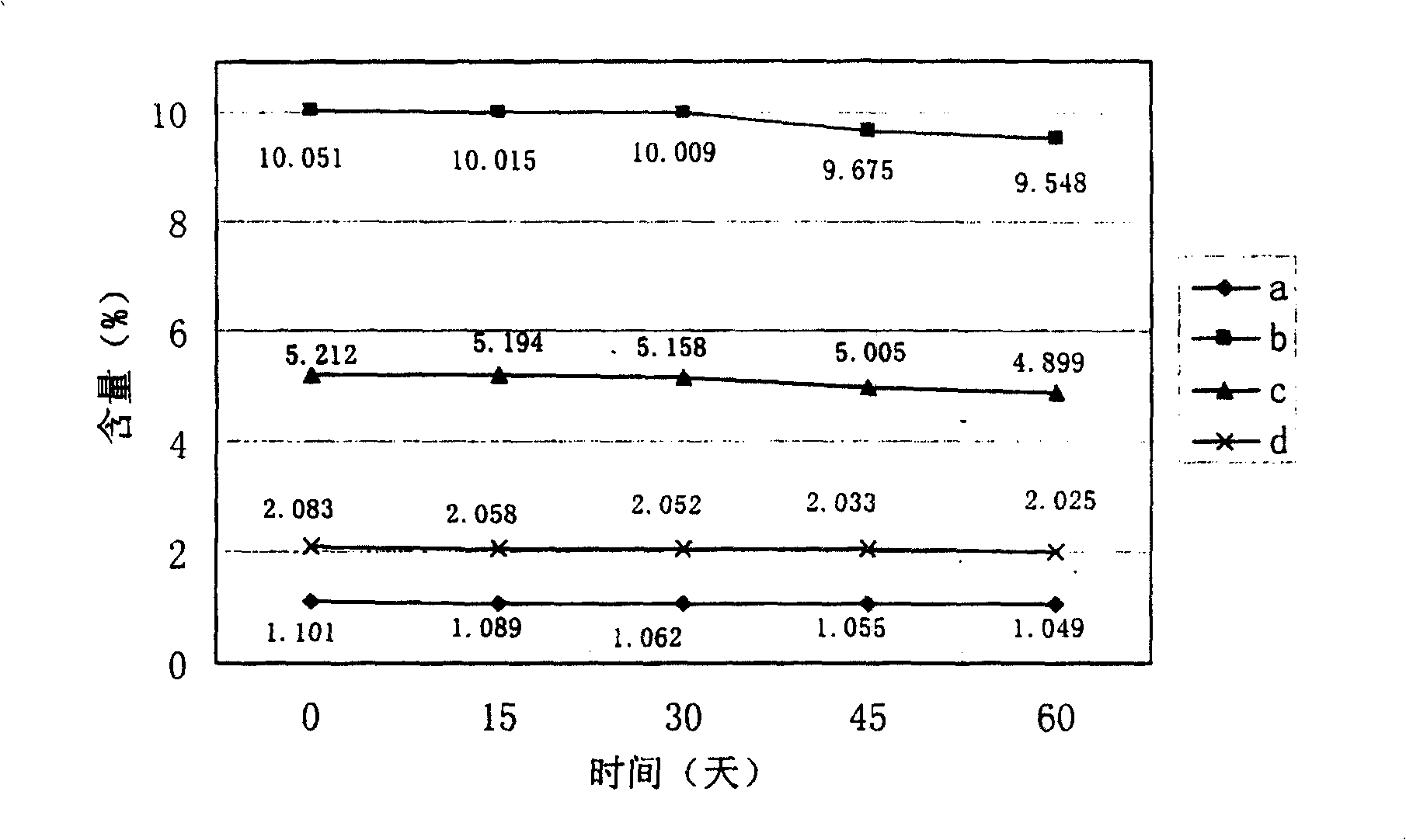

[0051]Put 200g of water into the container, slowly add 26g of modified starch under stirring, stir well, let it stand overnight to dissolve it. 20% natural β-carotene oil 50g, add 1g Tween 60, natural V C After 0.5 g, the oil bath was heated to 190° C. to dissolve it to form an oil phase. Put 200g of water into the container, add 5g of maltodextrin, 6g of β-cyclodextrin, 1g of soybean lecithin, 8g of lactose, and 1g of potassium sorbate, stir and heat to 75°C, and heat the spare modified starch solution to 50°C. Add to the above solution to make the water phase. Add the oil phase to the water phase, keep the temperature at 75°C, and emulsify with an emulsifier at 3000 rpm for 30 minutes. Homogenize the emulsified liquid with a pressure of 40kg / cm 2 10.05% natural beta-carotene microcapsules can be prepared by spray drying the homogenized material at an inlet temperature of 200°C and an outlet temperature of 90°C.

Embodiment 3

[0053] Put 100g of water into the container, slowly add 20g of modified starch under stirring state, stir well, let it stand overnight to make it dissolve. After adding 10 g of 5% natural β-carotene oil, 0.8 g of soybean lecithin and 0.1 g of TBHQ, the oil bath was heated to 120° C. to dissolve it to form an oil phase. Put 300g of water into the container, add 5g of maltodextrin, 5g of β-cyclodextrin, 0.7g of sorbitol fatty acid ester, 5g of glucose, and 0.5g of sodium benzoate, stir and heat to 50°C, and heat the spare modified starch solution to 40°C, added to the above solution to make the water phase. Add the oil phase to the water phase, keep the temperature at 60°C, and emulsify with an emulsifier at 2000 rpm for 10 minutes. Homogenize the emulsified liquid with a pressure of 30kg / cm 2 , the homogenized material is spray-dried at an inlet temperature of 150°C and an outlet temperature of 70°C to produce 1.06% natural beta-carotene microcapsules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com