Paillette drive method for needling equipment and driving device

A driving method and technology of sequins, applied in the direction of automatic control embroidery machines, sewing equipment, sewing machine components, etc., can solve the problems of sequins such as actual error and error accumulation increase, difficult operation, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. A sequin driving method for sewing equipment. It includes a cloth feeding step and a sewing step, and also includes the following steps:

[0025] (1) Sequin driving step synchronous with the cloth feeding step: design a sequin driving mechanism, which has a sequin driving rod, and the end of the sequin driving rod can be inserted into the center hole of the sequin to drive the sequin together with the sequin belt, and drive The step length is just equal to the center hole distance between two sequins;

[0026] (2) Sequin center hole recognition step: design a sequin recognition circuit, when the end of the sequin drive rod falls into the center hole of the next sequin, the information of the sequin can be automatically recognized and converted into a switch electrical signal, and provide it to the computerized control system;

[0027] (3) Identification of the diameter of the sequins and adjustment of the sequin drive mechanism: the computer control system...

Embodiment 2

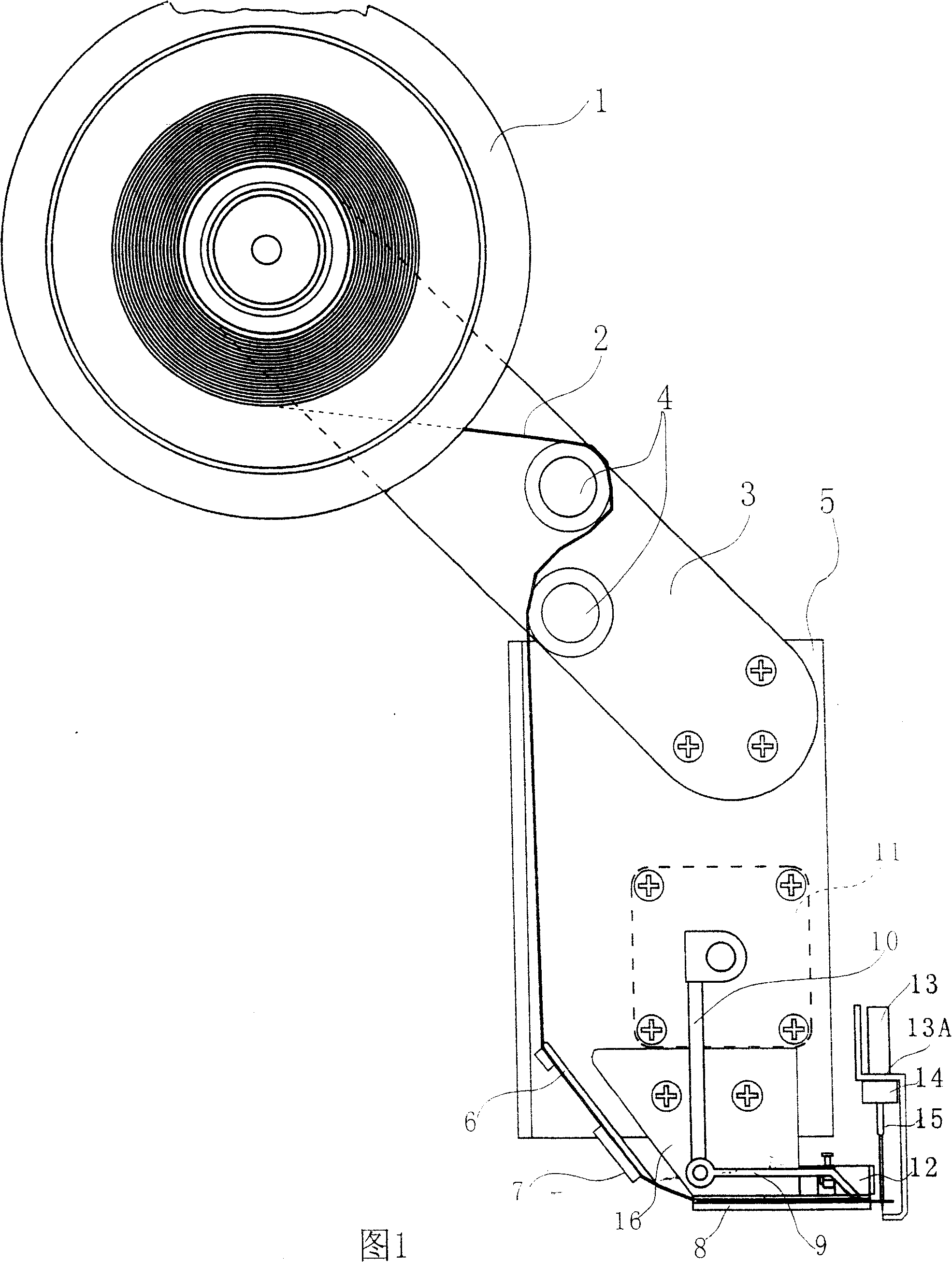

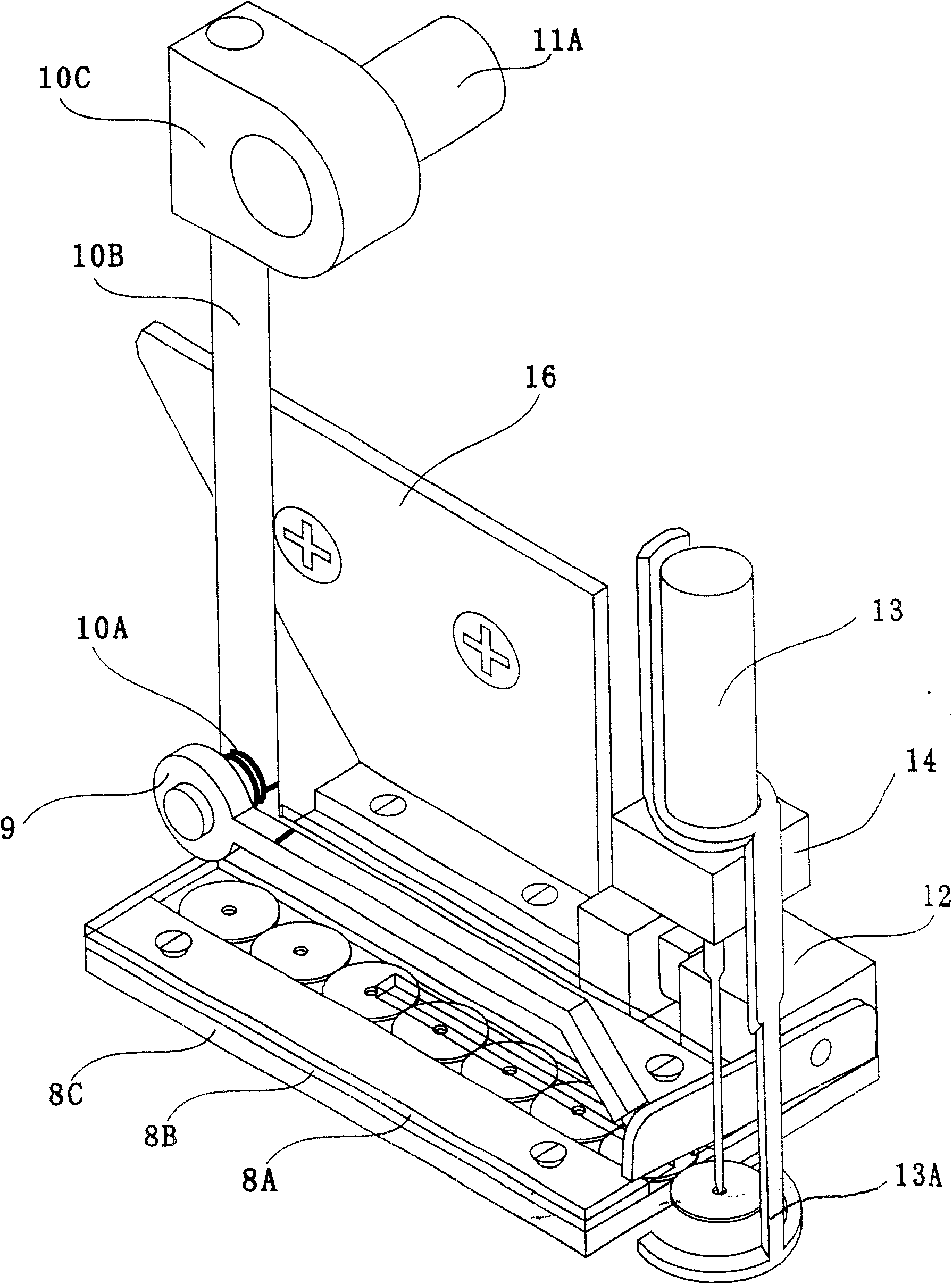

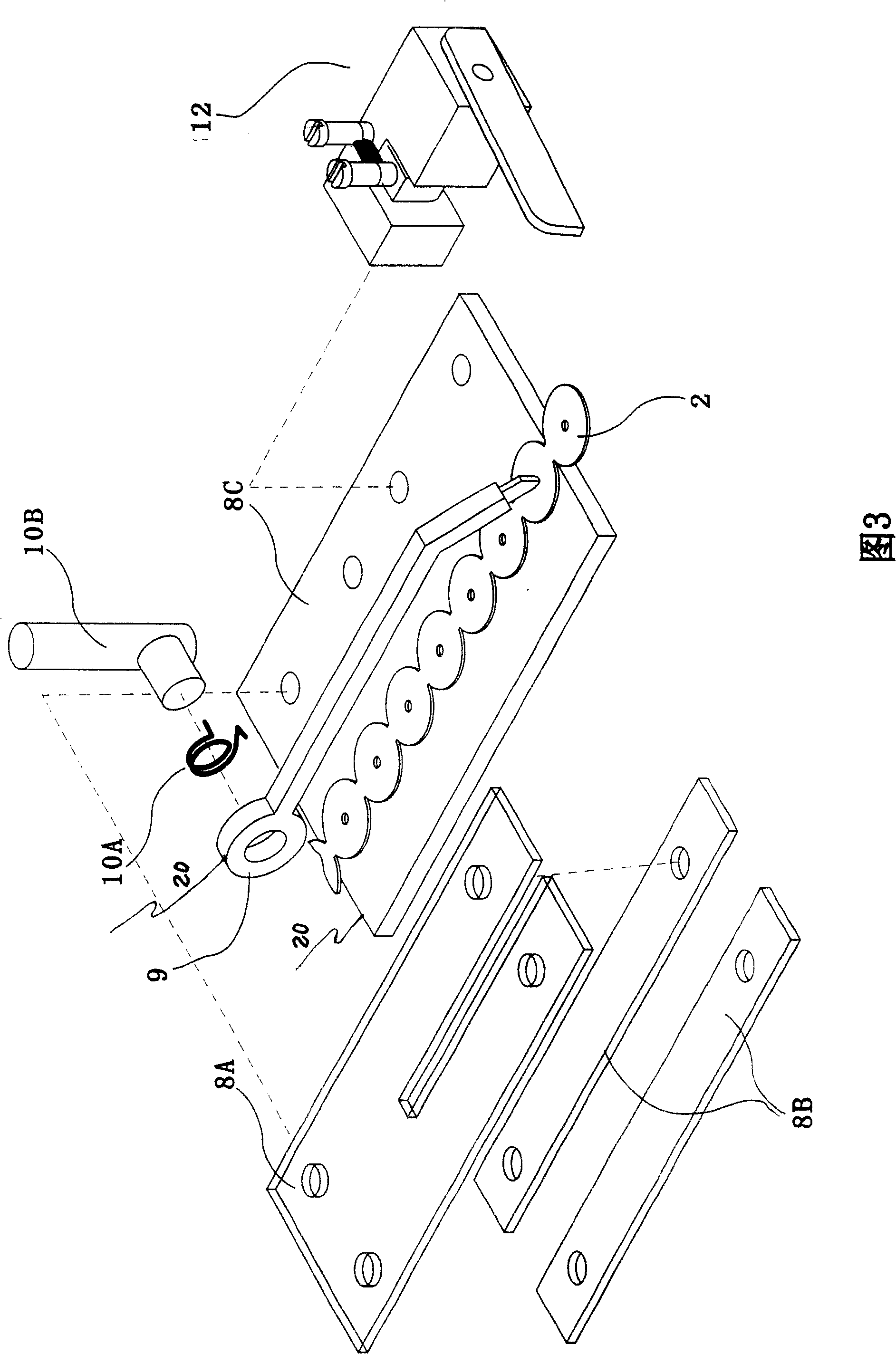

[0029] Example 2. A sequin drive device for sewing equipment, as shown in Fig. 1 to Fig. 7 . It includes a frame, a platen and a machine head installed on the frame, a power and transmission system installed between the frame and the machine head, and a computer control system installed on the machine head. One side of the machine head is also equipped with a sequin drive mechanism. It includes a chassis assembly (8) mounted on the platform, an adjusting part (16) fixed on the chassis (8), a connecting plate (5) fixed on the adjusting part (16), a connecting plate (5) fixed on the connecting plate (5) The sequin disc support (3), the sequin disc (1) installed on the sequin disc support (3), the upper and lower tension pulleys (4) installed on the sequin disc support (3), fixed on the sequin disc support The guide plate (6) and the centering mechanism (7) on (3) are wrapped in the sequin disc (1) and its ends successively go around the upper and lower two tensioning wheels (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com