Magnetic recording medium and method for manufacturing same

A technology for magnetic recording medium and production method, applied in magnetic recording, magnetic recording layer, data recording, etc., can solve problems such as insufficient coercive force of magnetic particles, excessive media noise, low recording density media noise, etc., to achieve Suppresses magnetic transition noise, suppresses media noise, and improves recording density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

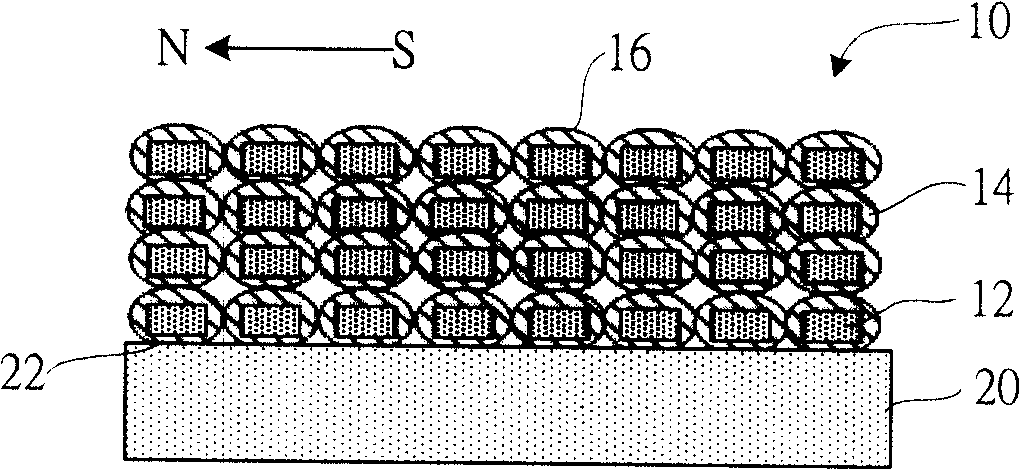

[0022] see figure 1 , the horizontal magnetic recording medium provided by the first embodiment of the present invention includes a magnetic recording layer 10, and the magnetic recording layer 10 includes: a plurality of carbon nanospheres 14; For the magnetic particles 12 in a separated state, the magnetic field orientations of the magnetic particles 12 are substantially consistent, and are substantially parallel to the surface 16 of the magnetic recording layer.

[0023] Magnetic particles 12 can be selected iron, cobalt, nickel or alloys thereof used in the prior art; as CoPtCr, CoCrTa, CoCrPtB, CoCrPtNi, CoCrPtTa, CoCrPtW, CoCrPtNb, CoCrPtC or CoCrPtTaNb etc., it is a hexagonal lattice structure, easy magnetization axis is the c-axis ( figure 1 where the length direction of the magnetic particles represents the c-axis). Depend on figure 1 It can be seen that the orientations of the easy magnetization axes of the magnetic particles 12 are basically the same, and they ar...

no. 2 example

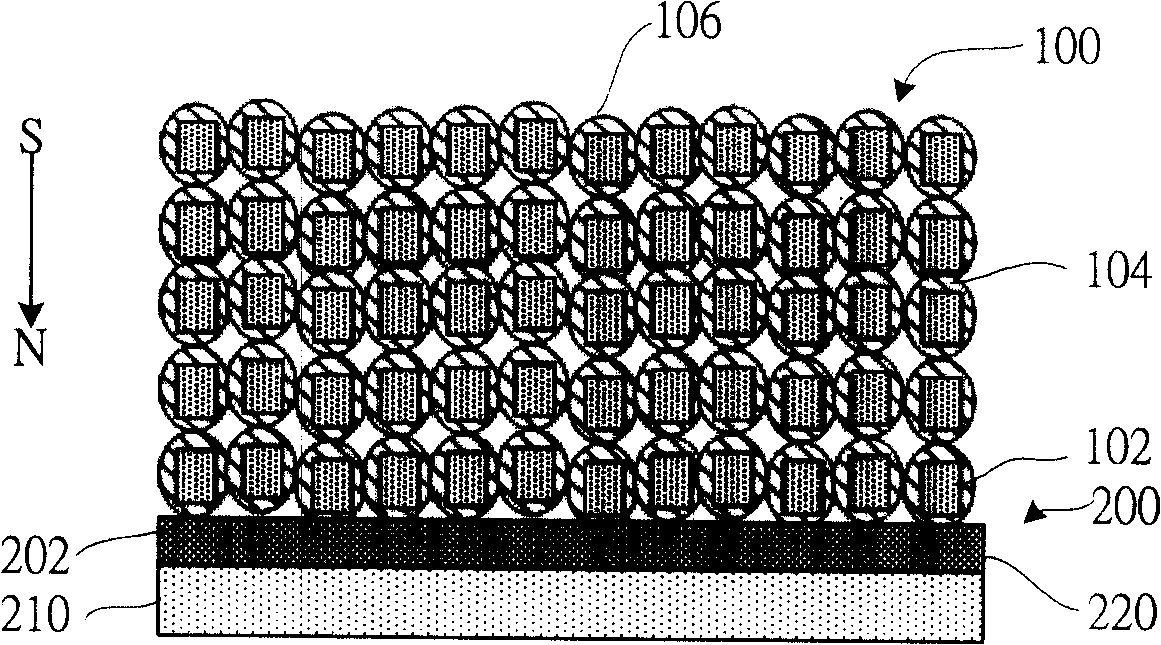

[0031] see figure 2 , the perpendicular magnetic recording medium provided by the second embodiment of the present invention includes a magnetic recording layer 100, and the magnetic recording layer 100 includes: a plurality of carbon nanospheres 104; For the magnetic particles 102 in a separated state, the magnetic field orientations of the magnetic particles 102 are basically the same, and they are basically perpendicular to the surface 106 of the magnetic recording layer.

[0032]Magnetic particles 102 can be selected iron, cobalt, nickel or alloys thereof used in the prior art; as CoPtCr, CoCrTa, CoCrPtB, CoCrPtNi, CoCrPtTa, CoCrPtW, CoCrPtNb, CoCrPtC or CoCrPtTaNb etc., it is a hexagonal lattice structure, easy magnetization axis is the c-axis ( figure 2 where the length direction of the magnetic particles represents the c-axis). Depend on figure 2 It can be seen that the orientations of the easy magnetization axes of the magnetic particles 102 are basically the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com