Accumulating conveyor for shield segment

A technology for storage and transportation machines and segments, which is applied in underground transportation, transportation and packaging, earthwork drilling and mining, etc., and can solve problems such as construction accidents, potential safety hazards of segments, and reduced construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

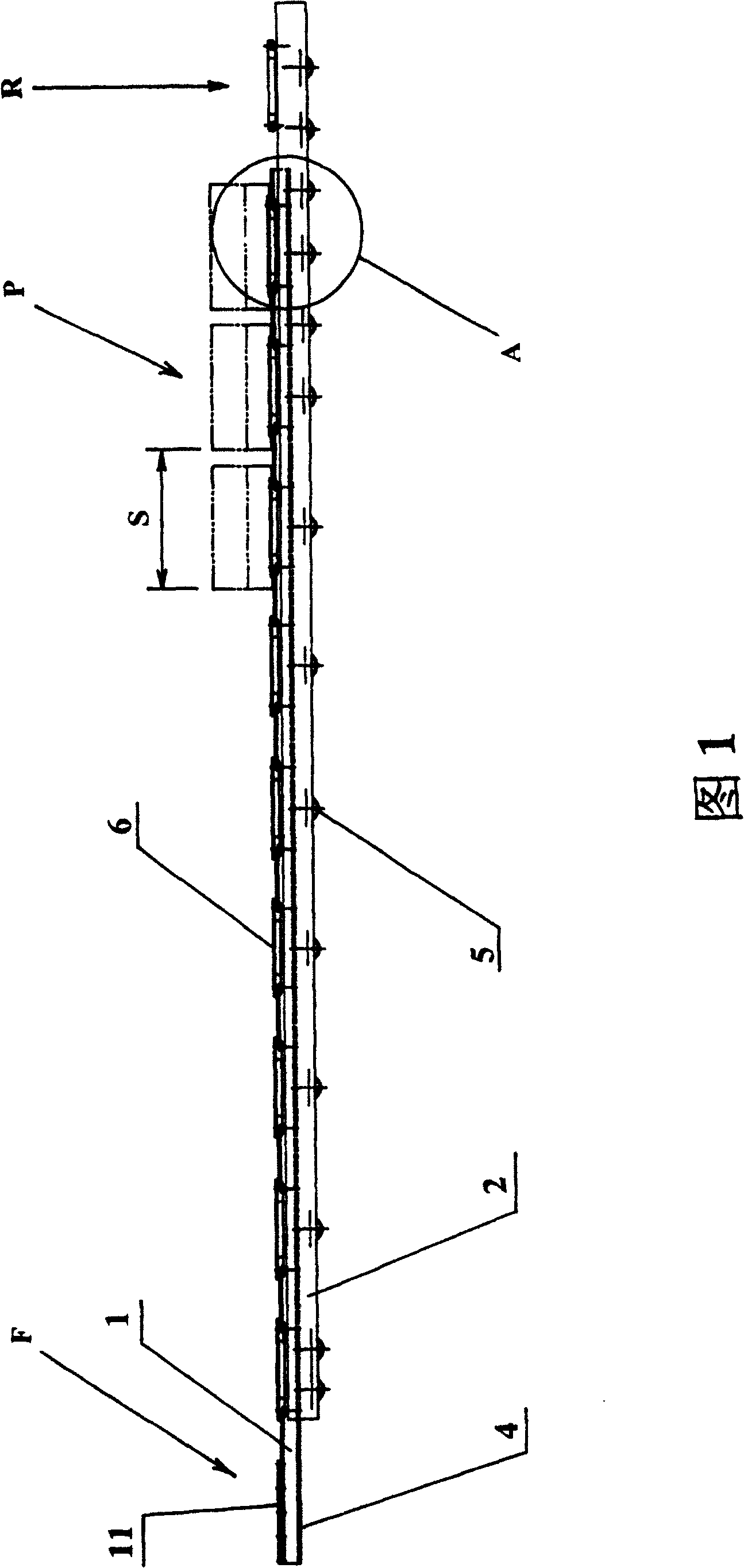

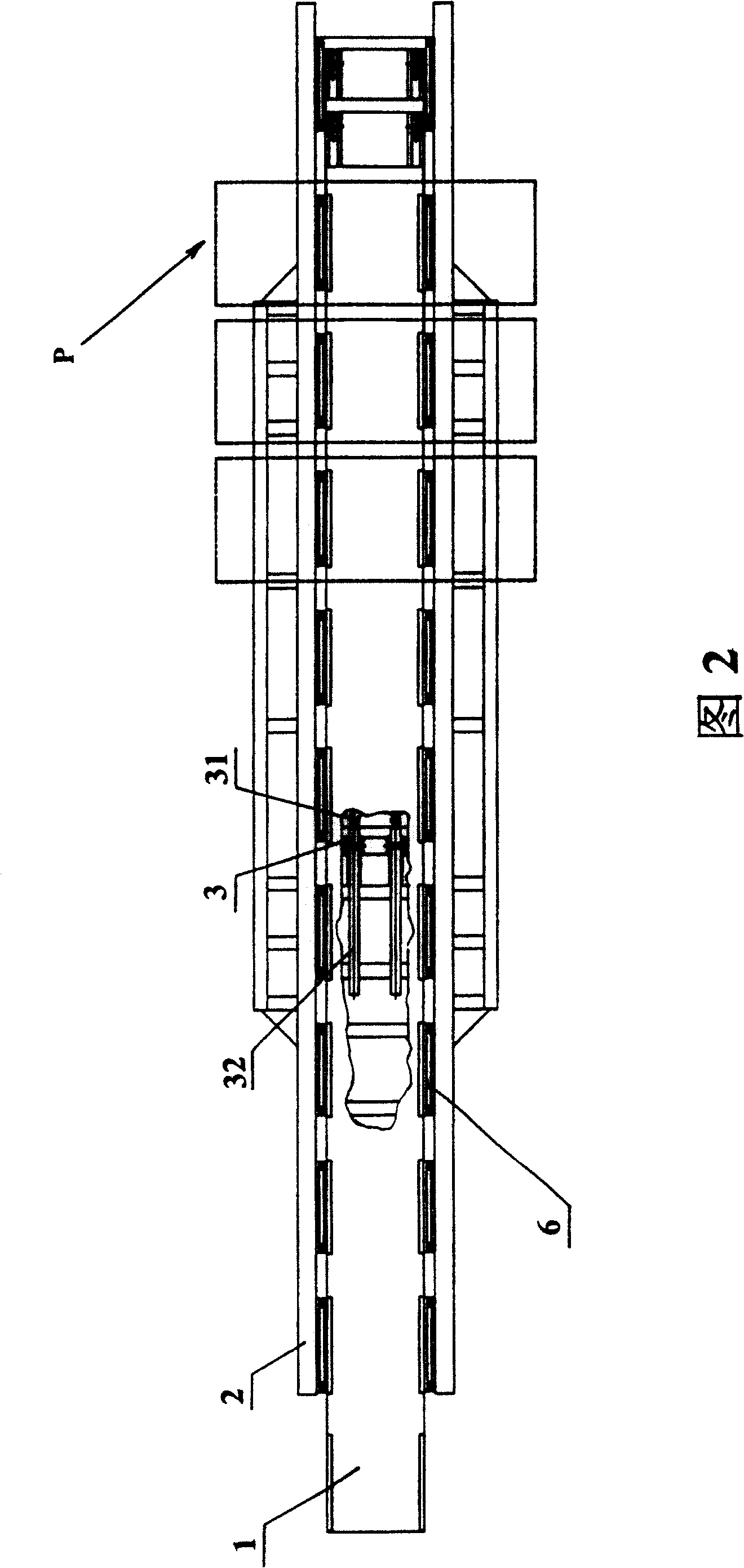

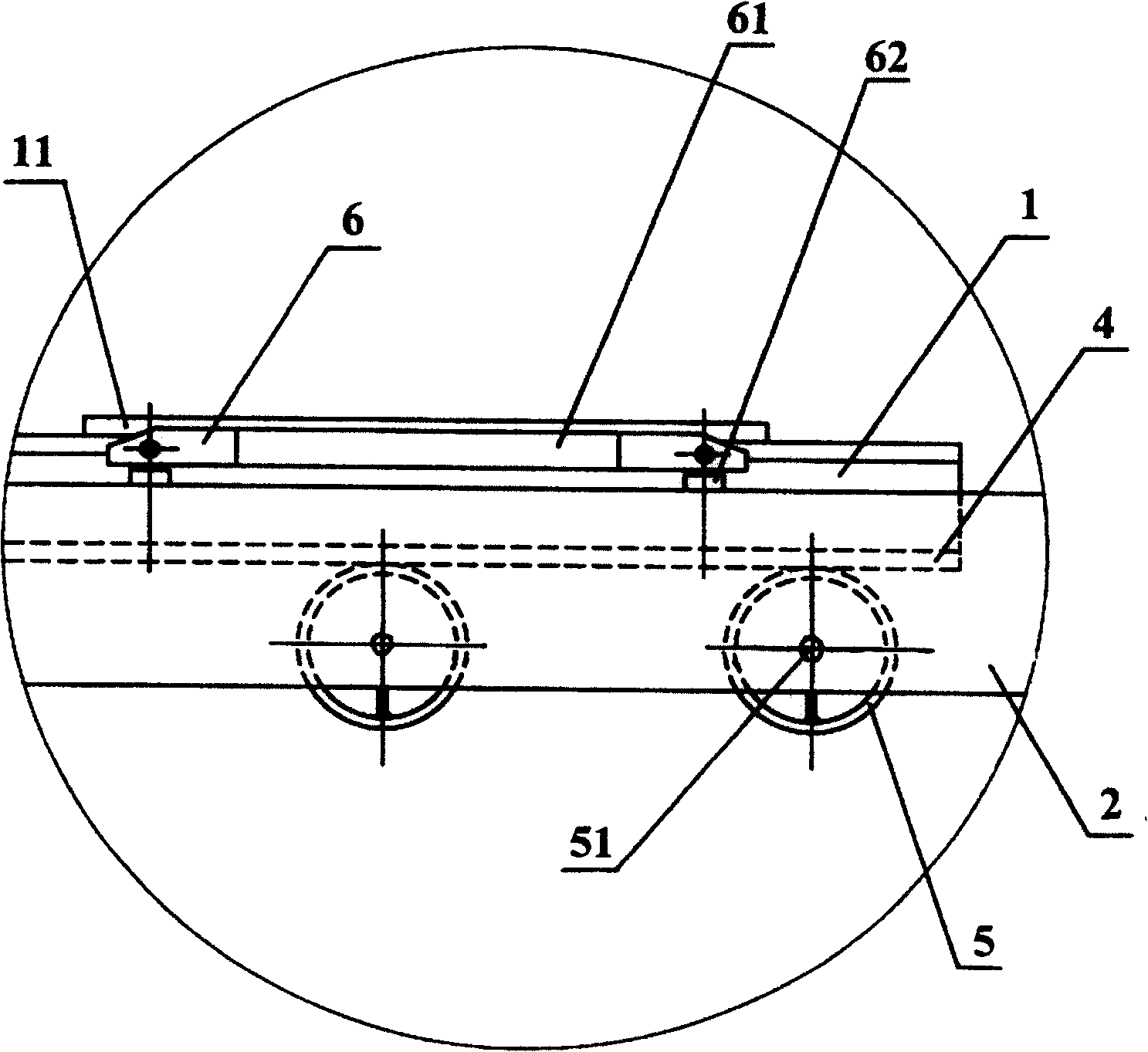

[0013] Please refer to Figure 1, Figure 2 and image 3 Structural schematic diagram of the present invention. The segment storage and transportation machine for shield tunneling shown in the figure is installed on the shield tunneling machine and advances together with the tunneling of the shield tunneling machine. It includes a mobile platform 1, a support platform 2, a group of traction hydraulic cylinders 3 and several jacking Hydraulic cylinder group 6. The support platform 2 is a steel structure with a certain length, which is a fixed support part of the entire shield segment storage and transportation machine, and it is longitudinally arranged on the subsequent frame of the shield machine, so that the shield machine segment The sheet storage and transportation machine is installed on the shield tunneling machine; the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com