Technique for preparing furnace coal combined coking with coals

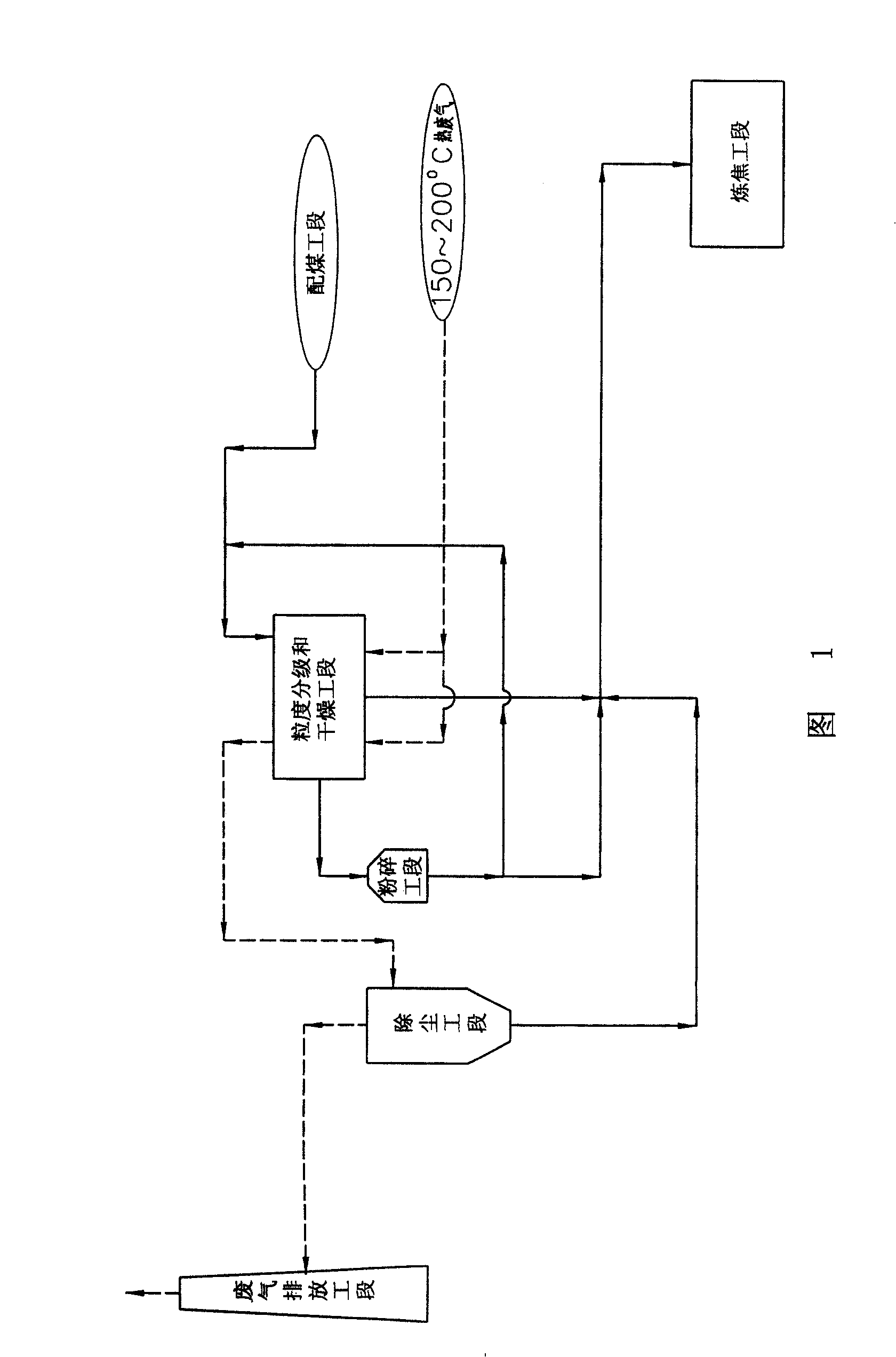

A technology for mixing coal and charging furnaces, which is applied in coking ovens, petroleum industries, etc., can solve the problems of large processing capacity of pulverizers, high power consumption of motors, and failure to meet fineness requirements, so as to increase bulk density and prolong service life , to ensure the effect of production operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

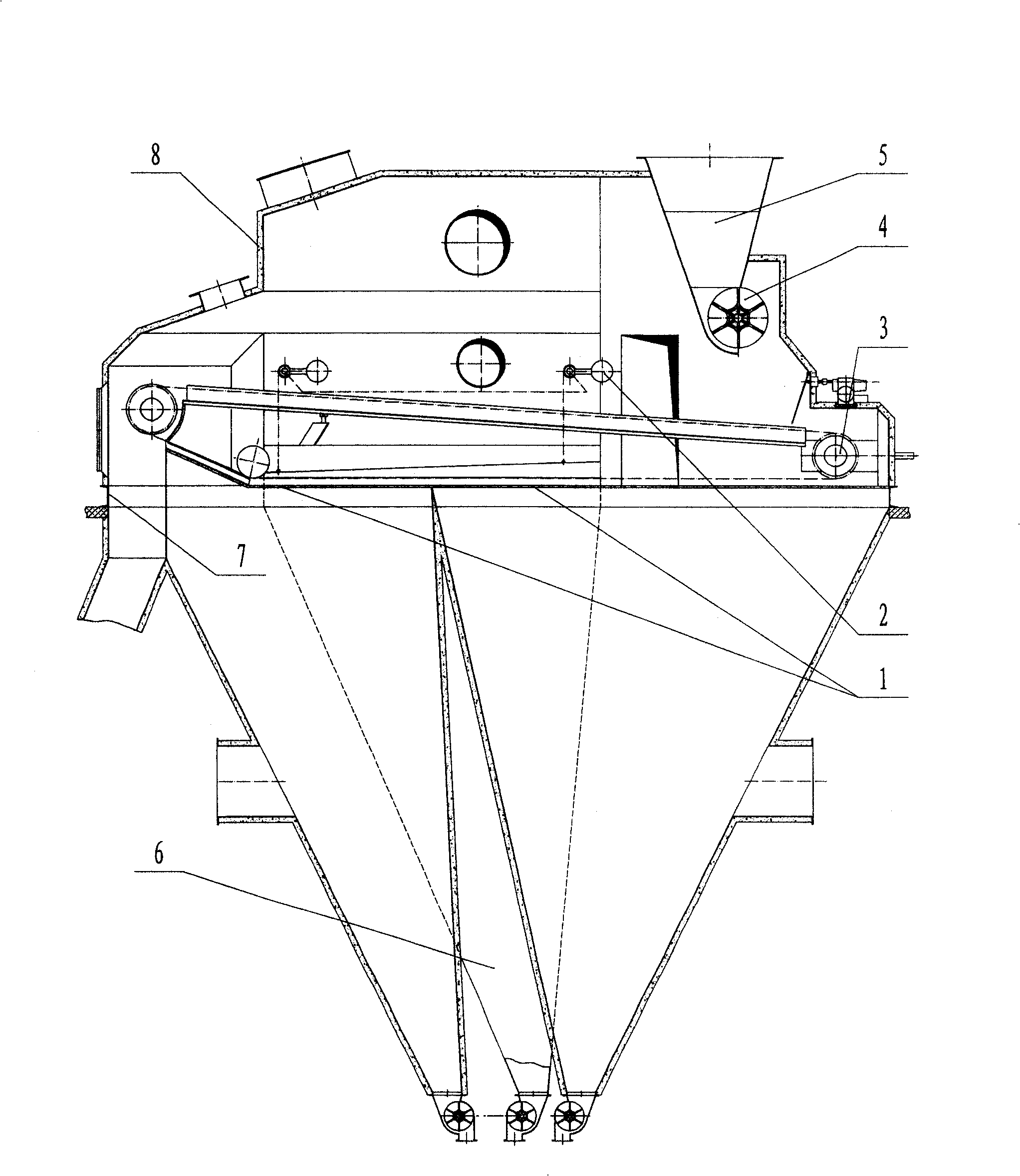

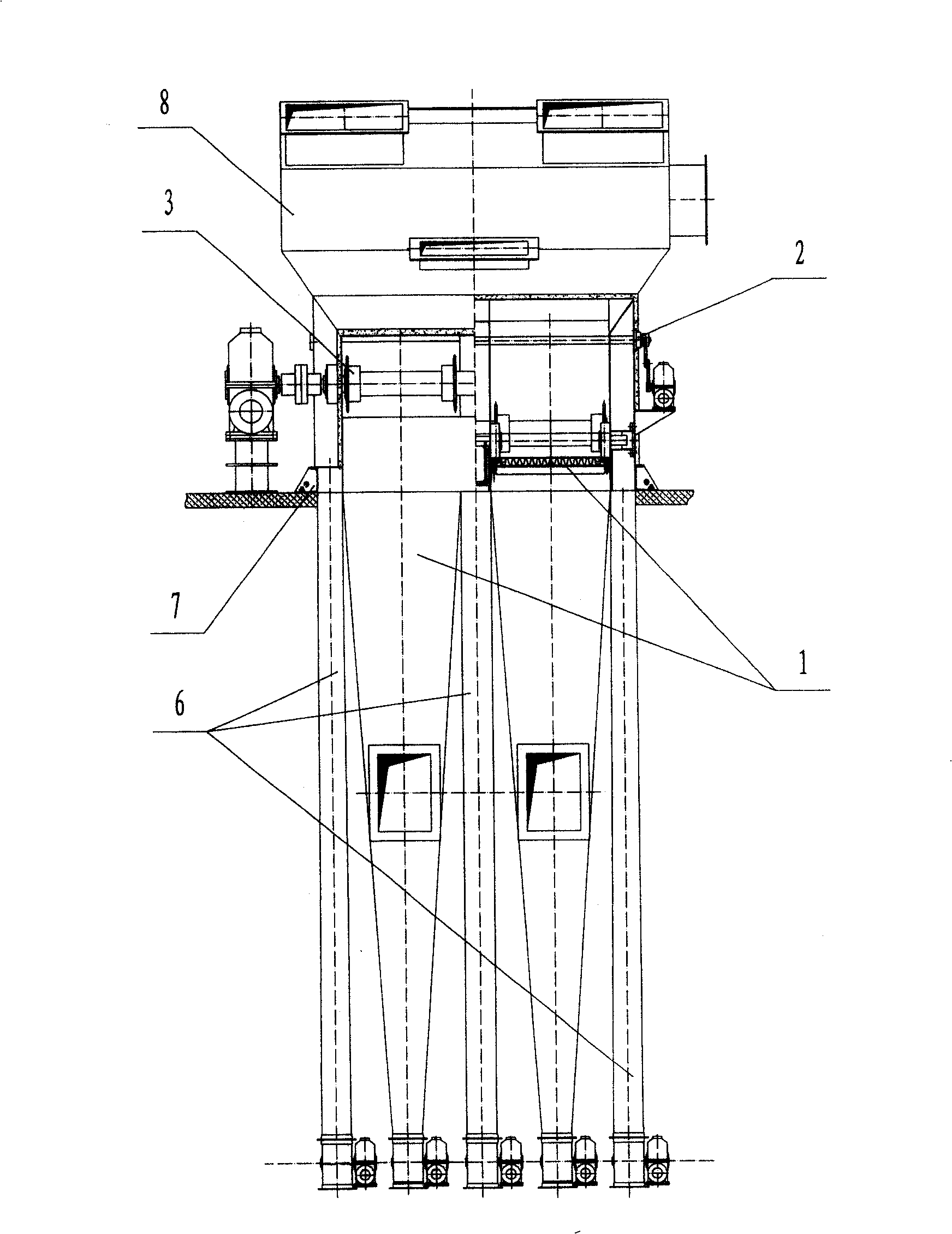

[0071] Example 1: Each single type of coking coal is blended into blended coal by an automatic coal blending device in the coal blending section according to the coal blending ratio determined by the coal blending test. The mixed coal is sent to the semi-boiling fluidized bed pneumatic separation dryer through the belt conveyor for particle size classification and moderate drying treatment. Dynamic grading and moderate drying treatment, the blended coal is divided into ≤3mm and >3mm grades; at the same time, the moisture content of the blended coal is reduced to 7.2% to 7.5%. Among them: ≤3mm grade furnace coal is discharged from the lower part of the semi-boiling fluidized bed pneumatic separation dryer, and is sent to the top of the coal tower by a belt conveyor for coking production in the coke oven; >3mm grade coal is discharged from the semi-boiling flow The discharge from the front of the fluidized bed pneumatic separation dryer is sent to the supporting pulverizer room ...

Embodiment 2

[0072] Example 2: Each single type of coking coal is blended into blended coal by an automatic coal blending device in the coal blending section according to the coal blending ratio determined by the coal blending test. The mixed coal is sent to the semi-boiling fluidized bed pneumatic separation dryer through the belt conveyor for particle size classification and moderate drying treatment. Dynamic grading and moderate drying treatment, the blended coal is divided into ≤3mm and >3mm grades; at the same time, the moisture content of the blended coal is reduced to 6.8% to 7.2%. Among them: ≤3mm grade furnace coal is discharged from the lower part of the semi-boiling fluidized bed pneumatic separation dryer, and is sent to the top of the coal tower by a belt conveyor for coking production in the coke oven; >3mm grade coal is discharged from the semi-boiling flow The discharge from the front of the fluidized bed pneumatic separation dryer is sent to the supporting pulverizer room ...

Embodiment 3

[0073] Embodiment 3: Each single type of coking coal is blended into blended coal by an automatic coal blending device in the coal blending section according to the coal blending ratio determined by the coal blending test. The mixed coal is sent to the semi-boiling fluidized bed pneumatic separation dryer through the belt conveyor for particle size classification and moderate drying treatment. Dynamic grading and moderate drying treatment, the blended coal is divided into ≤3mm and >3mm grades; at the same time, the moisture content of the blended coal is reduced to 6.5% to 6.8%. Among them: ≤3mm grade furnace coal is discharged from the lower part of the semi-boiling fluidized bed pneumatic separation dryer, and is sent to the top of the coal tower by a belt conveyor for coking production in the coke oven; >3mm grade coal is discharged from the semi-boiling flow The discharge from the front of the fluidized bed pneumatic separation dryer is sent to the supporting pulverizer ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com