Electric contact

A technology of electric contacts and contacts, which is applied in the field of electric contacts, can solve the problems of high cost and large amount of silver consumption, and achieve the effects of ensuring quality and service life, reducing product costs, and saving silver-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

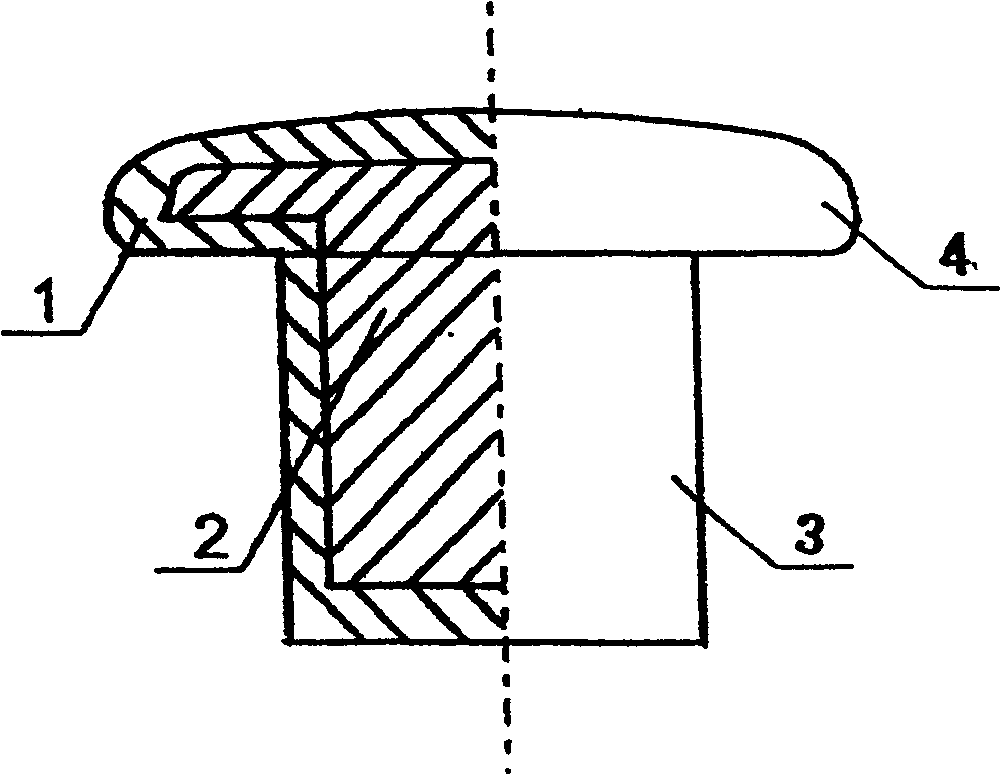

[0015] Embodiment 1, an electrical contact of the present invention includes an electrical contact neck 3 ( figure 1 ) and head 4, the whole electric contact is made of copper base 2, silver alloy composite layer 1 on the surface of copper base; , Titanium element mixture, its thickness is 250 microns.

[0016] The chemical composition weight percent of the silver alloy composite layer is 0.1-0.2% of the mixture of rare earth metal cerium and lanthanum, 0.05-0.2% of the mixture of zirconium, bismuth, indium and titanium elements with their own characteristics, and the balance is silver metal.

[0017] This product can be used on AC electrical appliances such as machine tools, communications, home appliances and various high-power relays within 30A / 220V-380V.

Embodiment 2

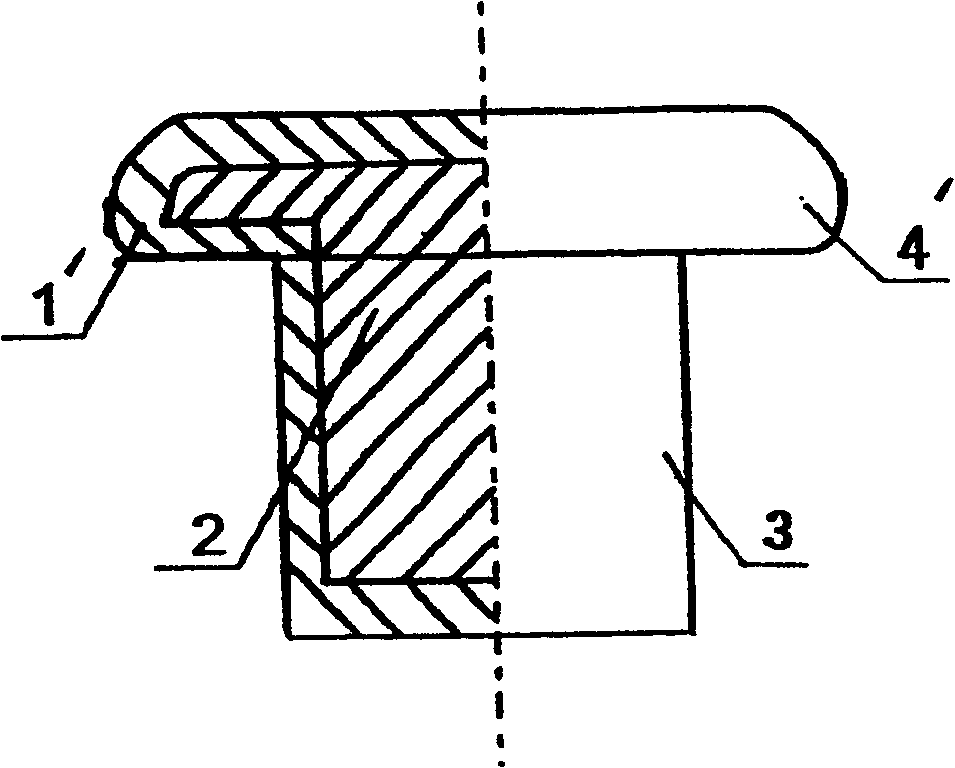

[0018] Embodiment 2, the electrical contact includes an electrical contact neck 3 and a head 4' ( figure 2 , with a flatter top). The entire contact is composed of a copper base 2 and a silver alloy composite layer 1' on the surface of the copper base; the silver alloy composite layer is mainly composed of silver, a mixture of rare earth metals cerium and lanthanum, and a mixture of zirconium, bismuth, indium, and titanium elements with their own characteristics. Its thickness is 150 microns.

[0019] The chemical composition weight percent of the silver alloy composite layer is 0.25-0.3% of the mixture of rare earth metal cerium and lanthanum, 0.2-0.25% of the mixture of zirconium, bismuth, indium and titanium elements with their own characteristics, and the balance is silver metal.

[0020] This product can be applied to all kinds of 5-12A / 3-24V relays, machine tools, communications, automobiles, ships, household appliances and other DC and AC electrical appliances.

Embodiment 3

[0021] Embodiment 3, the electrical contact includes an electrical contact neck (as shown in the figure figure 1 , 2 ). The entire electrical contact is composed of a copper matrix and a silver alloy composite layer on the surface of the copper substrate; the silver alloy composite layer is mainly composed of silver, a mixture of rare earth metals cerium and lanthanum, and a mixture of zirconium, bismuth, indium, and titanium elements with their own characteristics. is 8 microns.

[0022] The chemical composition weight percent of the silver alloy composite layer is 0.3-0.5% of rare earth metal cerium and lanthanum mixture, 0.25-0.3% of zirconium, bismuth, indium and titanium element mixture with their own characteristics, and the balance is silver metal.

[0023] This product can be applied to electric toys, telephones, miniature low-power relays and other DC and low-voltage electrical appliances with electrical contacts. There is also a wide range of application values ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com