Method for extracting indium tin from ito waste target through reduction electrolysis

A technology of electrolytic extraction and indium tin, which is applied in the direction of photography technology, equipment, photography auxiliary technology, etc., can solve the problems of complicated recycling process and high cost, and achieve the effect of simple operation, low production cost and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A waste target of 5 kg of ITO is used as a raw material, and the composition of the raw material is: 90% by weight of indium oxide and 10% by weight of tin oxide.

[0063] 1. Crushing and ball milling step S1

[0064] The raw material is crushed and ball milled to obtain more than 80% of the powder with a particle size below -120 mesh.

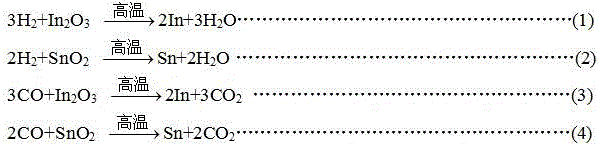

[0065] 2. Indium tin reduction step S2

[0066] Put the pulverized ITO waste target powder into the hydrogen reduction furnace, pass in hydrogen, then control the reduction temperature to 200°C, and the reduction reaction time to 60 minutes, and reduce indium oxide and tin oxide to metal indium and metal tin, indium and The recovery rate of tin is more than 99.5%.

[0067] 3. Anode casting step S3

[0068] Metal indium and tin are melted and cast under the cover of solid potassium hydroxide, soaked in 8% hydrochloric acid for 5 minutes, then washed with hot distilled water at 80°C for 2 minutes, and put on an acid-resistant bag to ob...

Embodiment 2

[0072] A waste target of 5 kg of ITO is used as a raw material, and the composition of the raw material is: 90% by weight of indium oxide and 10% by weight of tin oxide.

[0073] 1. Crushing and ball milling step S1

[0074] The raw material is crushed and ball milled to obtain more than 85% of the powder with a particle size below -120 mesh.

[0075] 2. Indium tin reduction step S2

[0076] Put the pulverized ITO waste target powder into the hydrogen reduction furnace, pass in hydrogen, then control the reduction temperature to 290°C, and the reduction reaction time is 50 minutes, and reduce indium oxide and tin oxide to metal indium and metal tin, indium and The recovery rate of tin is more than 99.5%.

[0077] 3. Anode casting step S3

[0078] Metal indium and tin are melted and cast under the cover of solid potassium hydroxide, soaked in 9% hydrochloric acid for 4 minutes, then washed with hot distilled water at 70°C for 3 minutes, and put on an acid-resistant bag to obta...

Embodiment 3

[0082] A waste target of 5 kg of ITO is used as a raw material, and the composition of the raw material is: 90% by weight of indium oxide and 10% by weight of tin oxide.

[0083] 1. Crushing and ball milling step S1

[0084] The raw material is crushed and ball milled to obtain more than 88% of the powder with a particle size below -120 mesh.

[0085] 2. Indium tin reduction step S2

[0086] Put the pulverized ITO waste target powder into the hydrogen reduction furnace, pass in hydrogen, then control the reduction temperature to 400°C, and the reduction reaction time is 30 minutes to reduce indium oxide and tin oxide to metal indium and metal tin, indium and The recovery rate of tin is more than 99.5%.

[0087] 3. Anode casting step S3

[0088] Metal indium and tin are melted and cast under the cover of solid sodium hydroxide, soaked in 12% hydrochloric acid for 3 minutes, then washed with hot distilled water at 50°C for 2 minutes, and put on an acid-resistant bag to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com