Dust-proof plug, feeding pipe joint, feeding pipe and its bulk packing machine

The technology of feeding pipe and plug is applied in the field of dry powder material processing equipment, which can solve the problems of environmental pollution and other problems, and achieve the effect of increasing the amount of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

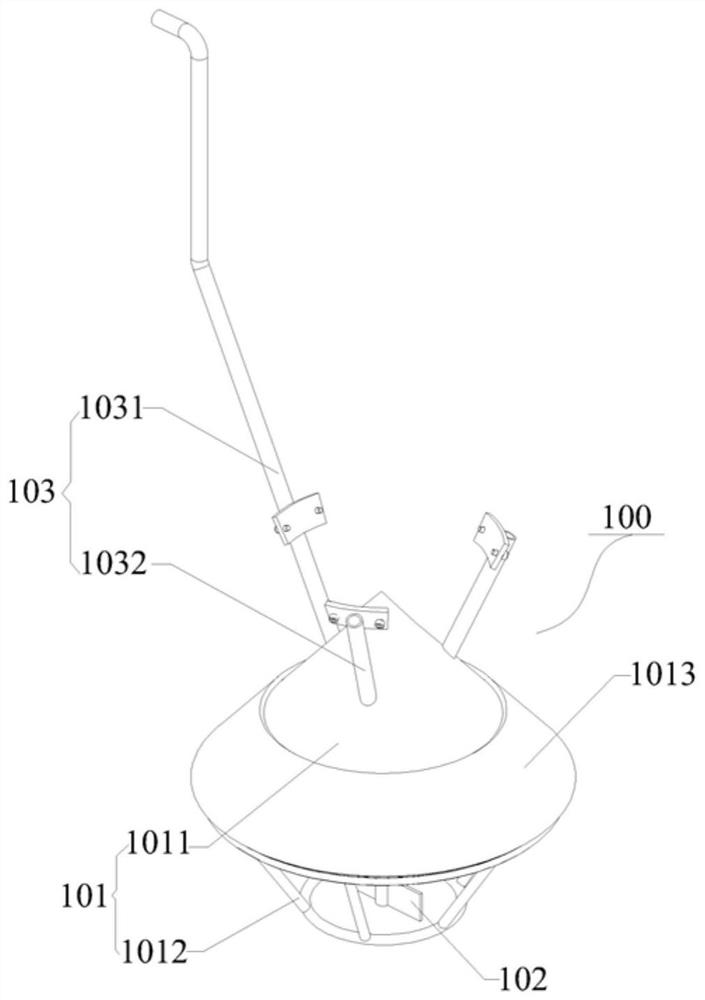

[0051] The dust-proof plug 100 provided by the present invention, such as figure 1 As shown, it includes a plug body 101 , a level gauge 102 and a connecting member 103 .

[0052] The plug body 101 is mainly used to block the bottom opening of the outer connector 202 of the feeding pipe 300. After the feeding of the feeding pipe 300 is completed, due to the connection between the outer connector 202 and the flexible connector 203, the outer connector 202 The plug body 101 is just sealed to the bottom opening of the outer connector 202 due to the gravitational force to move one end downward.

[0053] The material level gauge 102, the same as the traditional material level gauge 102, is mainly used to measure the loading capacity of the bulk truck. The material level sensor is also installed on the material level gauge 102. The material level sensor detects the amount of material in the bulk truck. When the material reaches When the content is certain, the material level sensor...

Embodiment 2

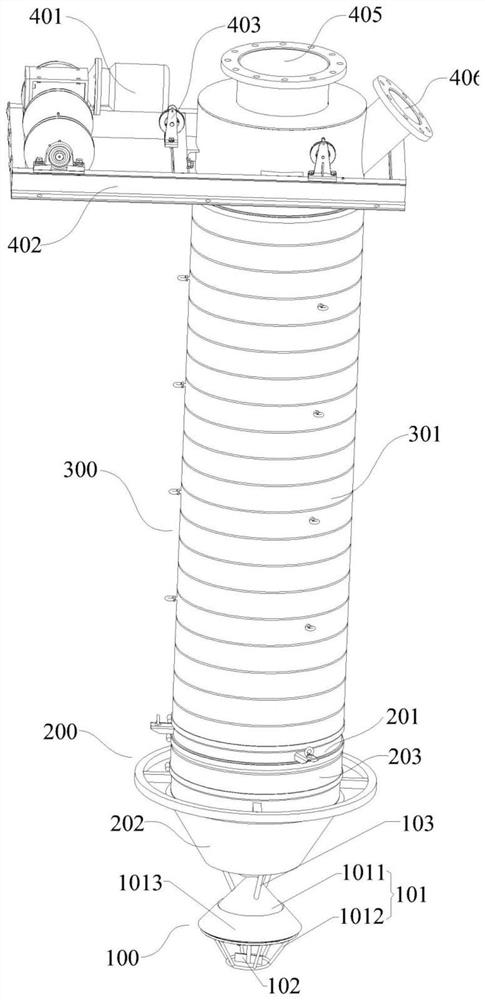

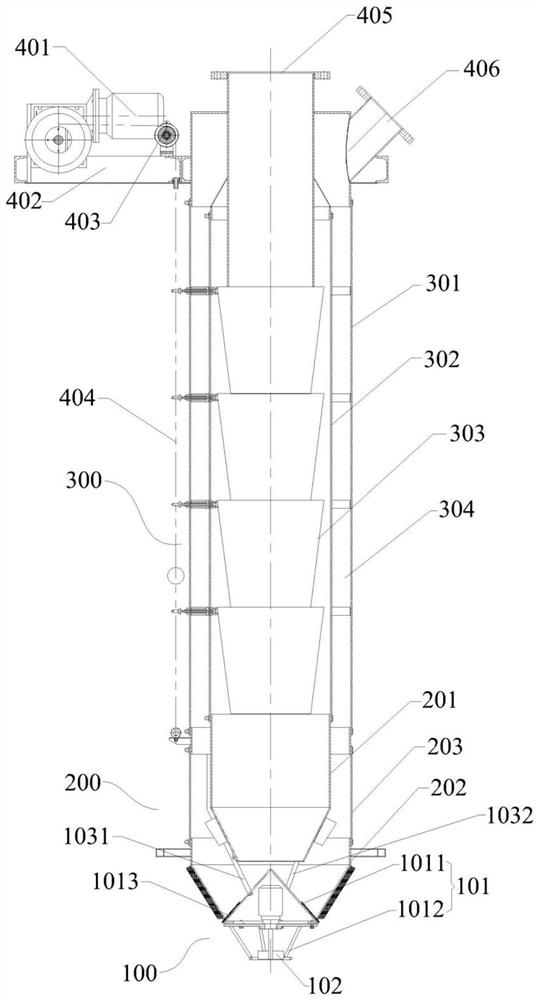

[0070] The feeding pipe joint 200 provided by the present invention includes the dust-proof plug 100 of Embodiment 1, and also includes an inner connector 201, an outer connector 202 and a flexible connector 203, such as figure 2 and image 3 As shown, the inner connector 201 is installed inside the outer connector 202 and can move relative to the outer connector 202. The outer connector 202 is connected to the outer flexible bag 301 through a flexible connector 203, and the dust-proof plug 100 is hoisted Below the inner connector 201 , as the inner connector 201 moves up and down, the dust-proof plug 100 and the outer connector 202 move relative to each other to seal and open the bottom opening of the outer connector 202 .

[0071] In this embodiment, through the cooperation of the inner connector 201, the outer connector 202, the flexible connector 203 and the dust-proof plug 100, in addition to realizing the plugging of the bottom opening of the outer connector 202 in Embo...

Embodiment 3

[0073] The feeding pipe 300 provided by the present invention includes the feeding pipe joint 200 of Embodiment 2, and also includes a hopper unit 303, an inner layer flexible bag 302 and an outer layer flexible bag 301, such as figure 2 and image 3 As shown, the guide hopper unit 303 is in the shape of a truncated cone, and the guide hopper unit 303 spliced in sequence forms a guide hopper. Connect the inner connector 201, the outer flexible bag 301 is connected to the outer connector 202 through the flexible connector 203, the inner connector 201 moves up and down and the inner flexible bag 302 stretches up and down, the inner connector 201 and the inner flexible bag 302 are connected to the outer A dust circulation channel 304 is formed between the connection head 202 and the outer stretchable bag 301 , and the dust generated by the dry powder material released by the inner connection head 201 is discharged upward through the dust circulation channel 304 .

[0074] Thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com