Method for comprehensively utilizing acid sludge under water-free condition

An anhydrous condition, acid residue technology, applied in the direction of solid waste removal, etc., can solve problems such as secondary pollution, achieve the effect of improving asphalt quality and avoiding water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

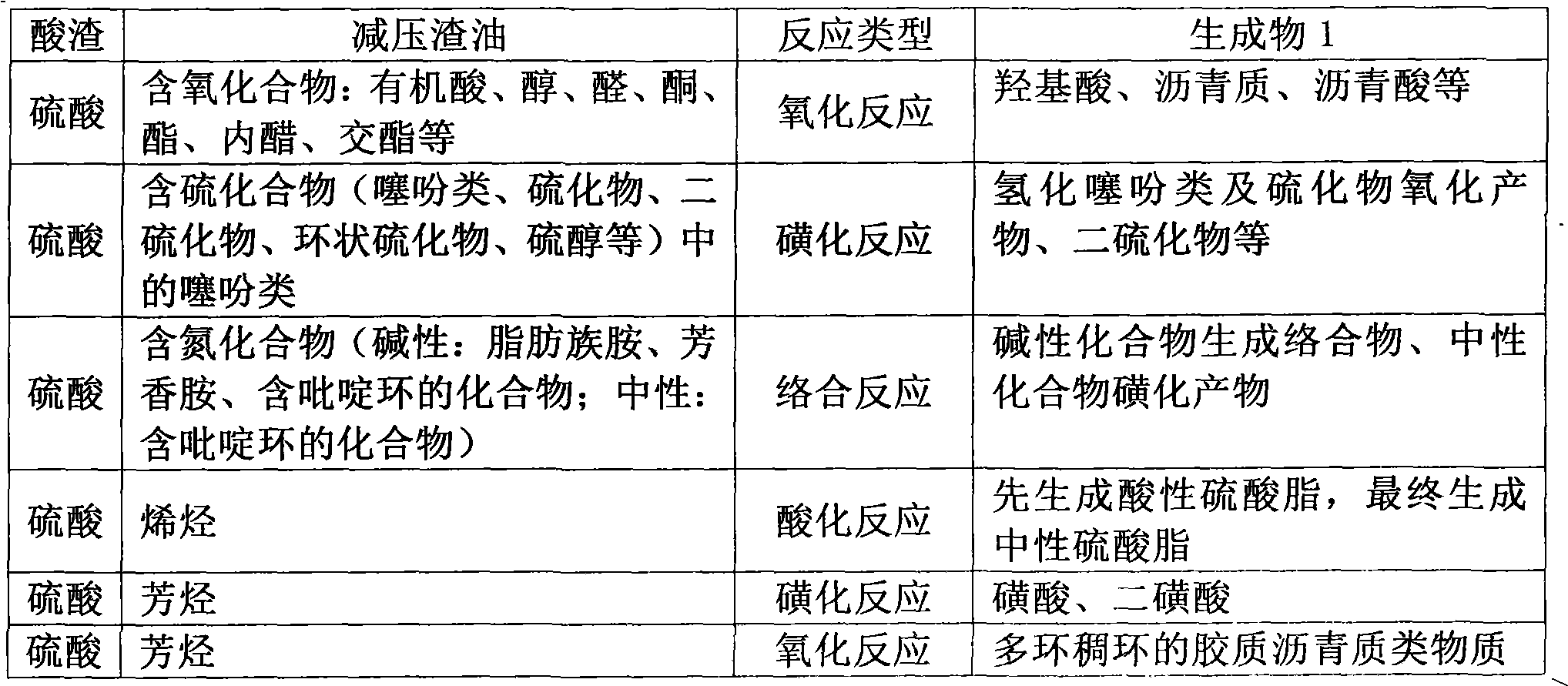

Method used

Image

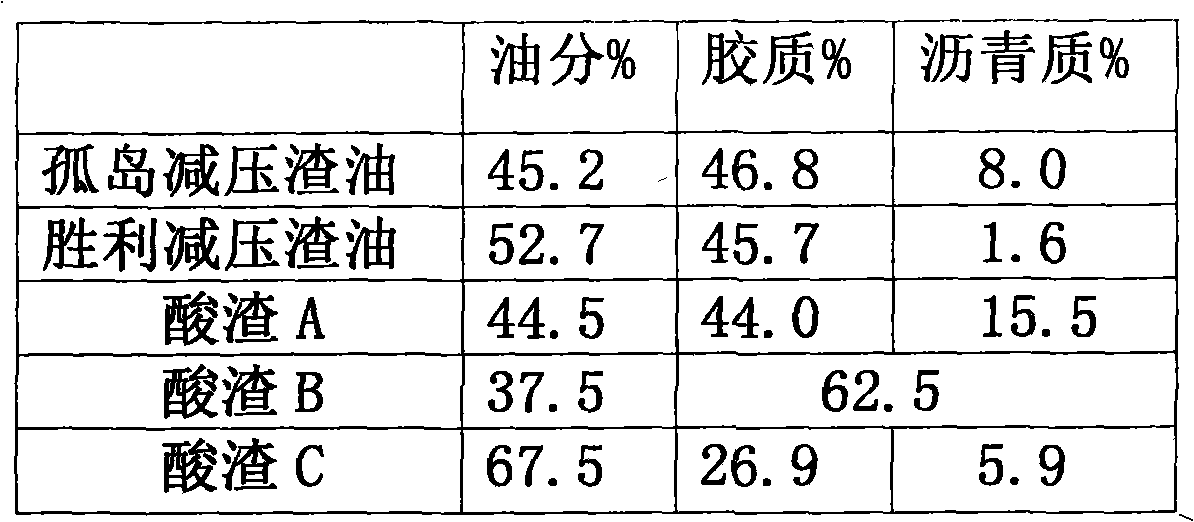

Examples

example 1

[0042] Store 50 grams of acid residue at 60°C for 4 to 6 days, remove the upper liquid, add 1000 grams of vacuum residue while stirring and heat to 180°C, then it starts to thicken, and at the same time due to SO 3 The volume of the gas expands, continue to stir, and after 10 minutes it begins to become thinner, SO 3 The amount of gas generated decreases, and after 15 minutes, the fluidity of the liquid recovers, and the volume recovers, which is regarded as the end of the reaction, and the product is a high-quality asphalt raw material. See acid slag blending experiment table.

example 2

[0044] Store 50 grams of acid residue naturally for 15 days, remove the upper liquid, add 1000 grams of vacuum residue while stirring and heat to 130 ° C, the acid residue begins to thicken after adding, and at the same time due to SO 3 The volume of the gas expands, continue to stir, and after 30 minutes it begins to become thinner, SO 3 The amount of gas generated is reduced, and after 45 minutes, the fluidity of the liquid is restored, and the volume is restored, which is regarded as the end of the reaction, and the product is a high-quality asphalt raw material. See acid slag blending experiment table.

example 3

[0046] Store 200 grams of acid residue naturally for 15 days, remove the upper liquid, and heat 1000 grams of vacuum residue to 150°C while stirring. After adding the acid residue, it begins to thicken. 3 The volume of the gas expands, continue to stir, and after 20 minutes it begins to become thinner, SO 3 The amount of gas generated is reduced, and after 30 minutes, the fluidity of the liquid is restored, and the volume is restored, which is regarded as the end of the reaction, and the product is a high-quality asphalt raw material. See the acid slag blending experiment table (Table 5) for the reaction process.

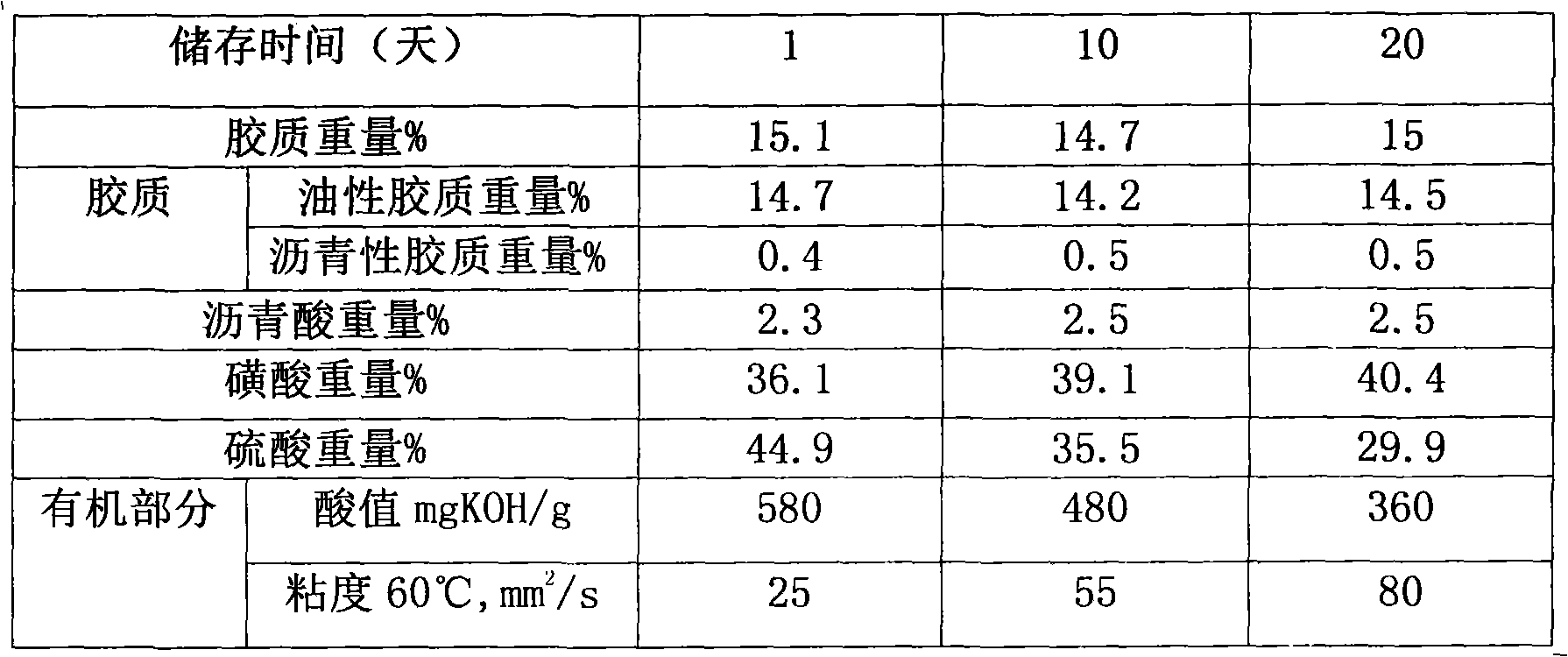

[0047] Table 5: Acid residue blending experiment table

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com