Electrothermal ring

An electric heating coil and electric heating wire technology, applied in the direction of the shape of the heating element, can solve the problems of cumbersome production process, assembly process, inconvenient installation and use, unreliable performance, etc., and achieves simple structure, prolonged service life, and enhanced thermal insulation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

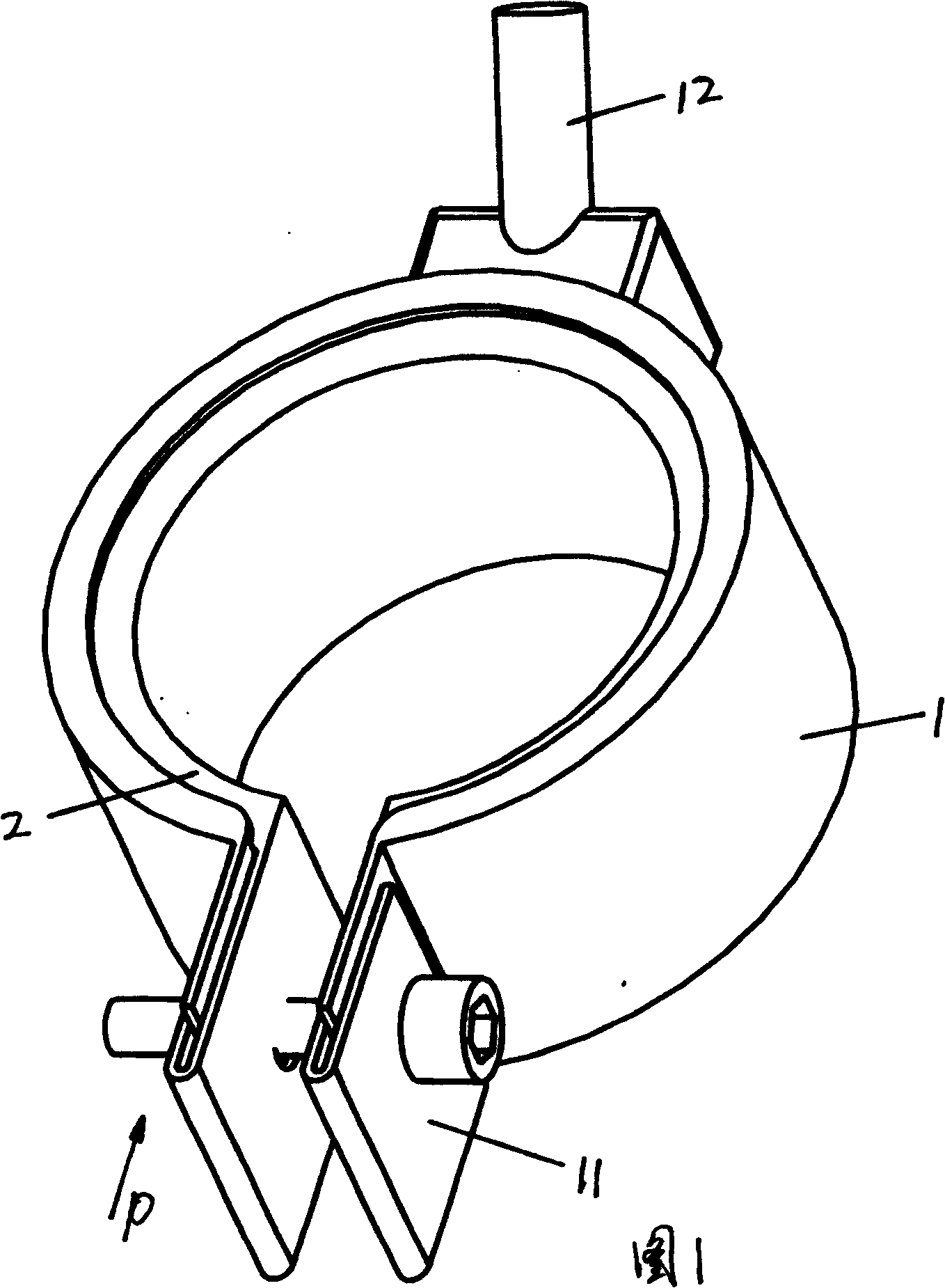

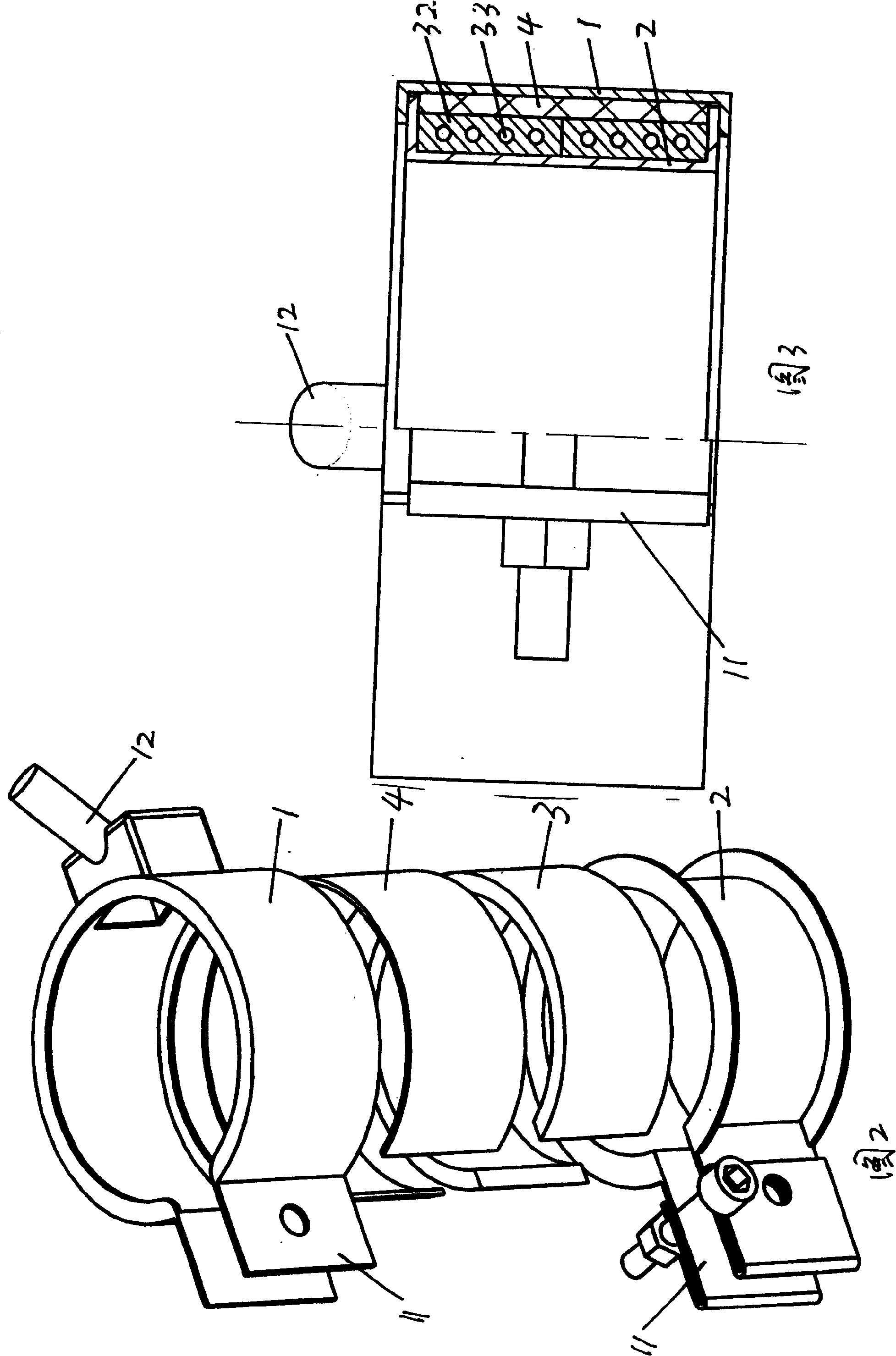

[0018] Embodiment: an electric heating coil, the structure of which includes an outer ring 1 and an inner ring 2 that play a supporting and fixing role, and a heating coil 3 and a heat insulation layer 4 are arranged between the two.

[0019] Among them, the outer ring 1 and the inner ring 2 are made of stainless steel by one-step stamping, and are in a "C" shape. The opening is provided with a fastening handle 11, and the side opposite to the opening is provided with an electrical connection on the outer ring 1. 12; Both rings are provided with side edges, the thickness of the side edge is equal to the thickness of the bottom edge, the side edge of the inner ring 2 is slightly smaller than the side edge of the outer ring 1, and the two are fastened together. See Figures 1, 2 and 3.

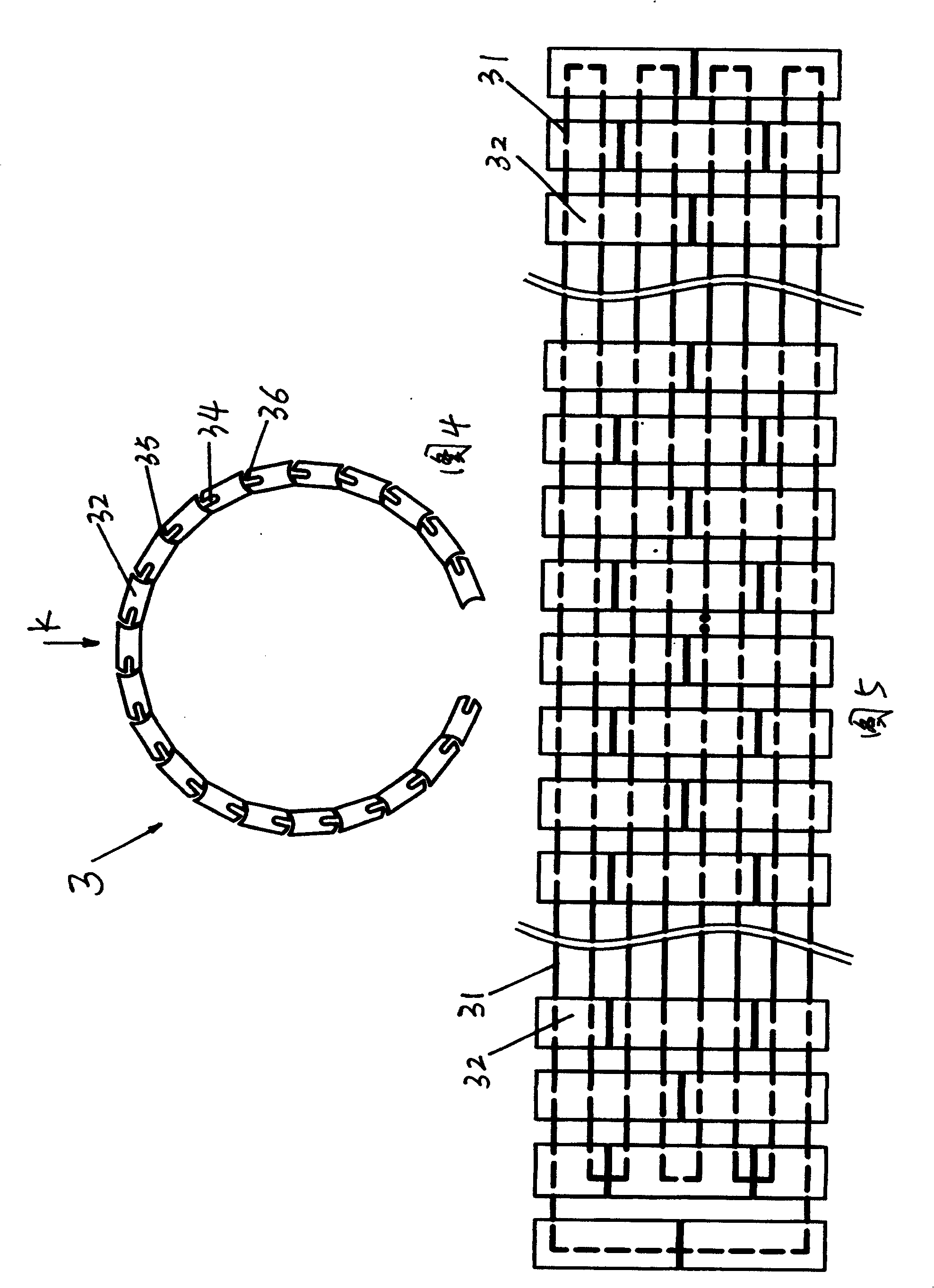

[0020] The heating coil 3 is composed of a plurality of ceramic skeletons 32 which are formed by a spring-like electric heating wire 31 threaded through. The ceramic skeleton is made of light-we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com