Method and apparatus for removing dust from a workpiece

A technology for working elements and exit devices, applied in the attachments of sawing machines, metal processing machinery parts, manufacturing tools, etc., can solve the problems of hindering the users of the jig saw, hindering the visibility of the cutting line, and low efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

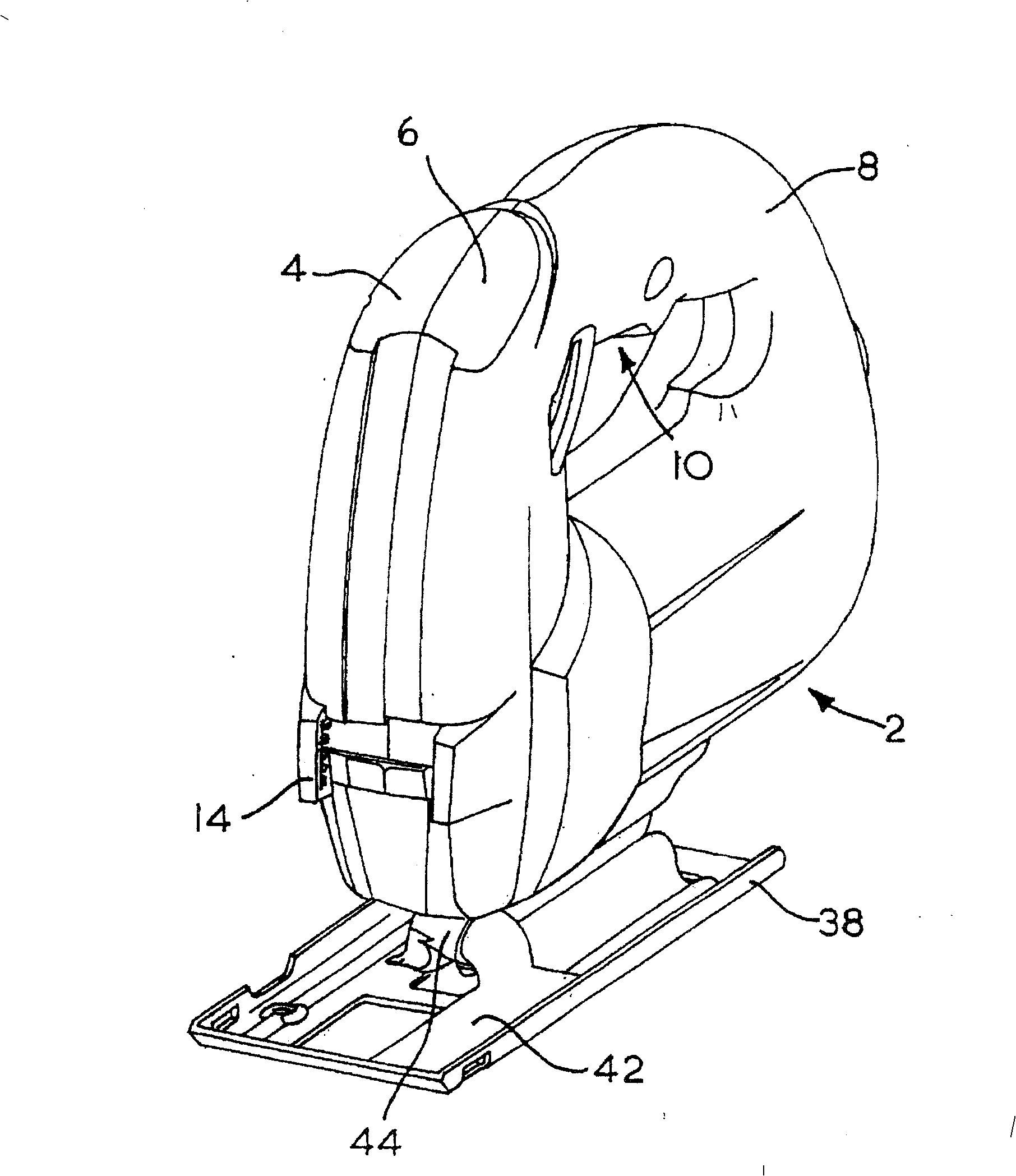

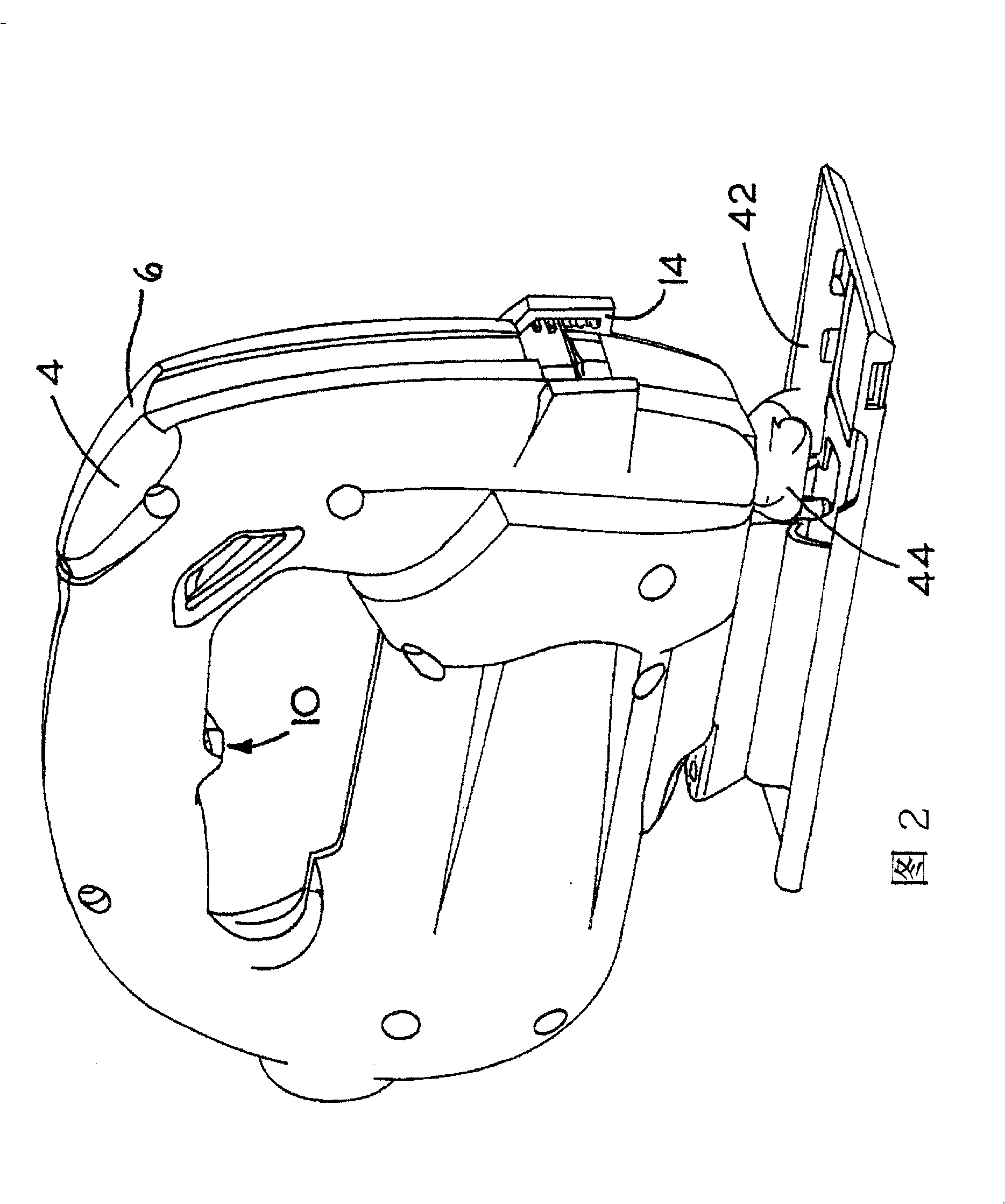

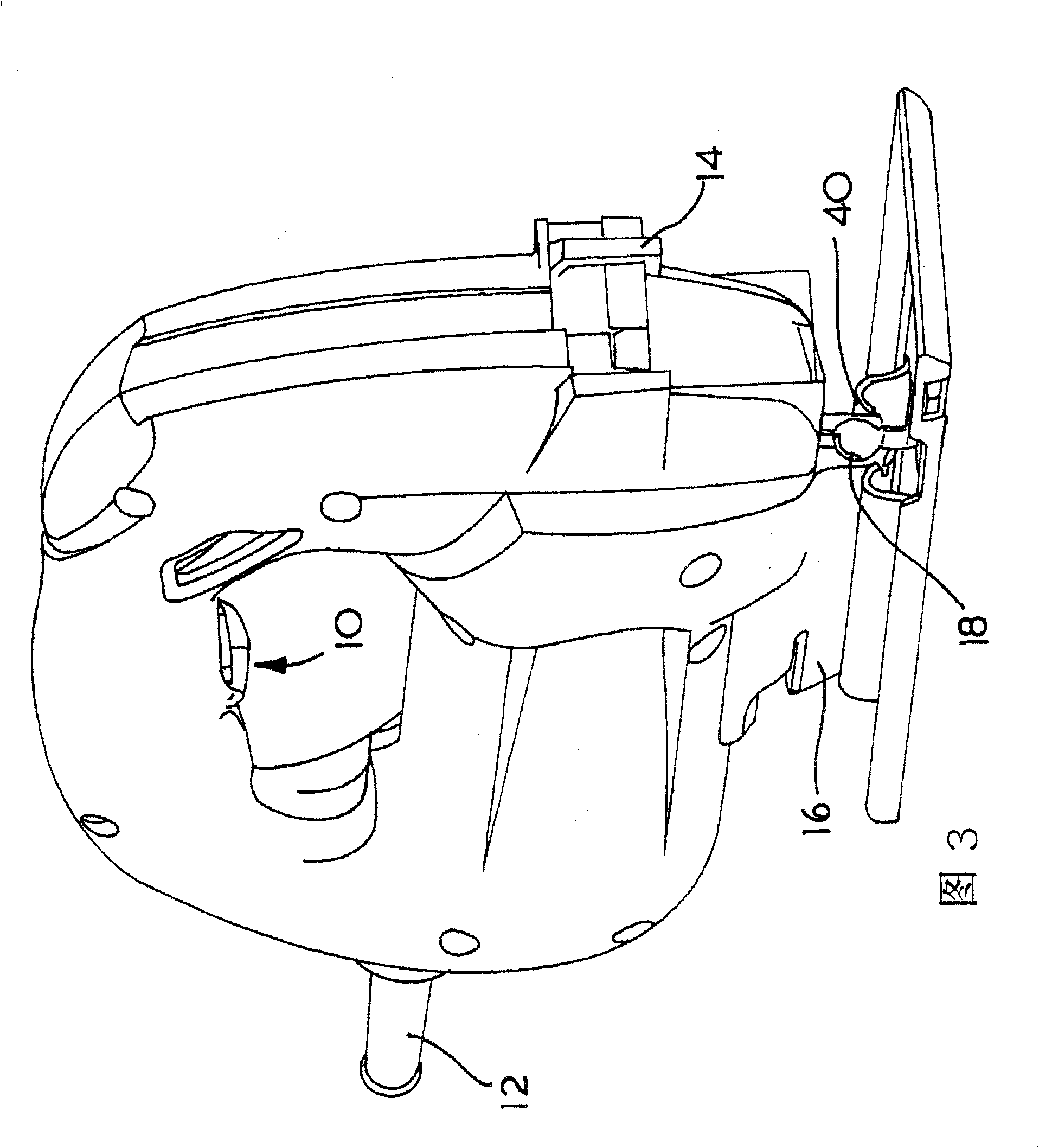

[0039] refer to Figure 1 to Figure 4 , the jigsaw 2 has a housing in the form of a clamshell consisting of two halves 4 , 6 . The jigsaw 2 forms a handle portion 8 to be grasped by the user and defines an area 10 in which a trigger (Fig. 7) is formed enabling the user to activate the jigsaw 2 to cut a workpiece (not shown).

[0040] Power is supplied to the jigsaw 2 via a power cord 12 (FIG. 3). The saw blade protection clamping mechanism 14 is arranged at the front of the jigsaw.

[0041] refer to Figure 4 Turning to Figure 7, it can be seen that the underside of the two clamshell halves 4, 6 forms a lower part 16, which provides a duct 18 through which air can be blown. As best seen in FIG. 5, the duct 18 is formed by slotting the clamshell half 6, thus forming a continuous slot 20, enabling the duct 18 to communicate with the jigsaw fan 22 (FIG. 7), as in the present invention. As is known to those skilled in the art, this fan is also used to cool the jigsaw motor dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com