Double-link and double-flywheel transmission device

A transmission device and double flywheel technology, which is applied in the direction of rider driving, transportation and packaging, machine/engine, etc., can solve the problems of high precision of crankshaft and crank coordination, difficult to achieve the pedal motion of the car, and large power loss. , to achieve the effect of simple structure, lower center of gravity and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

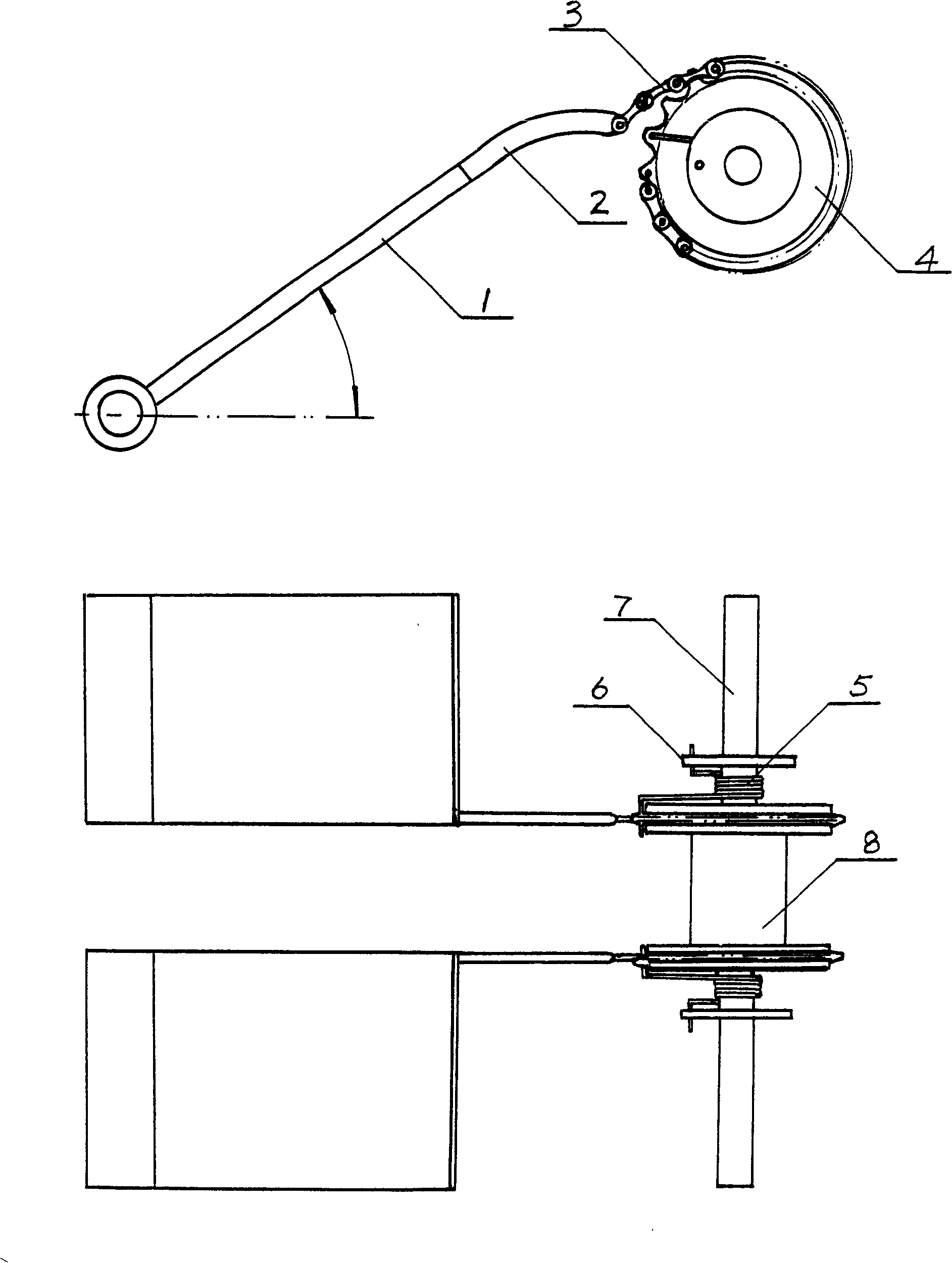

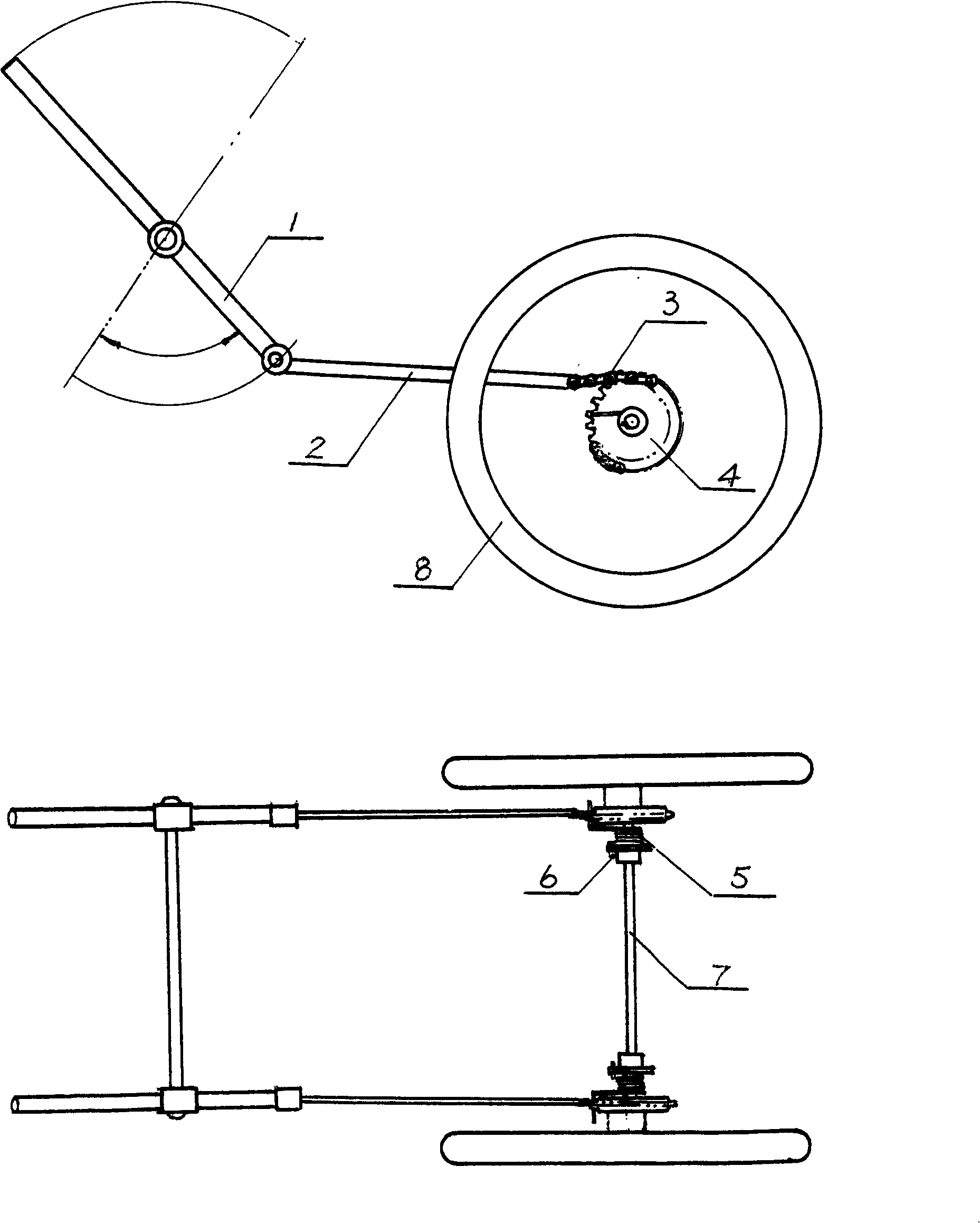

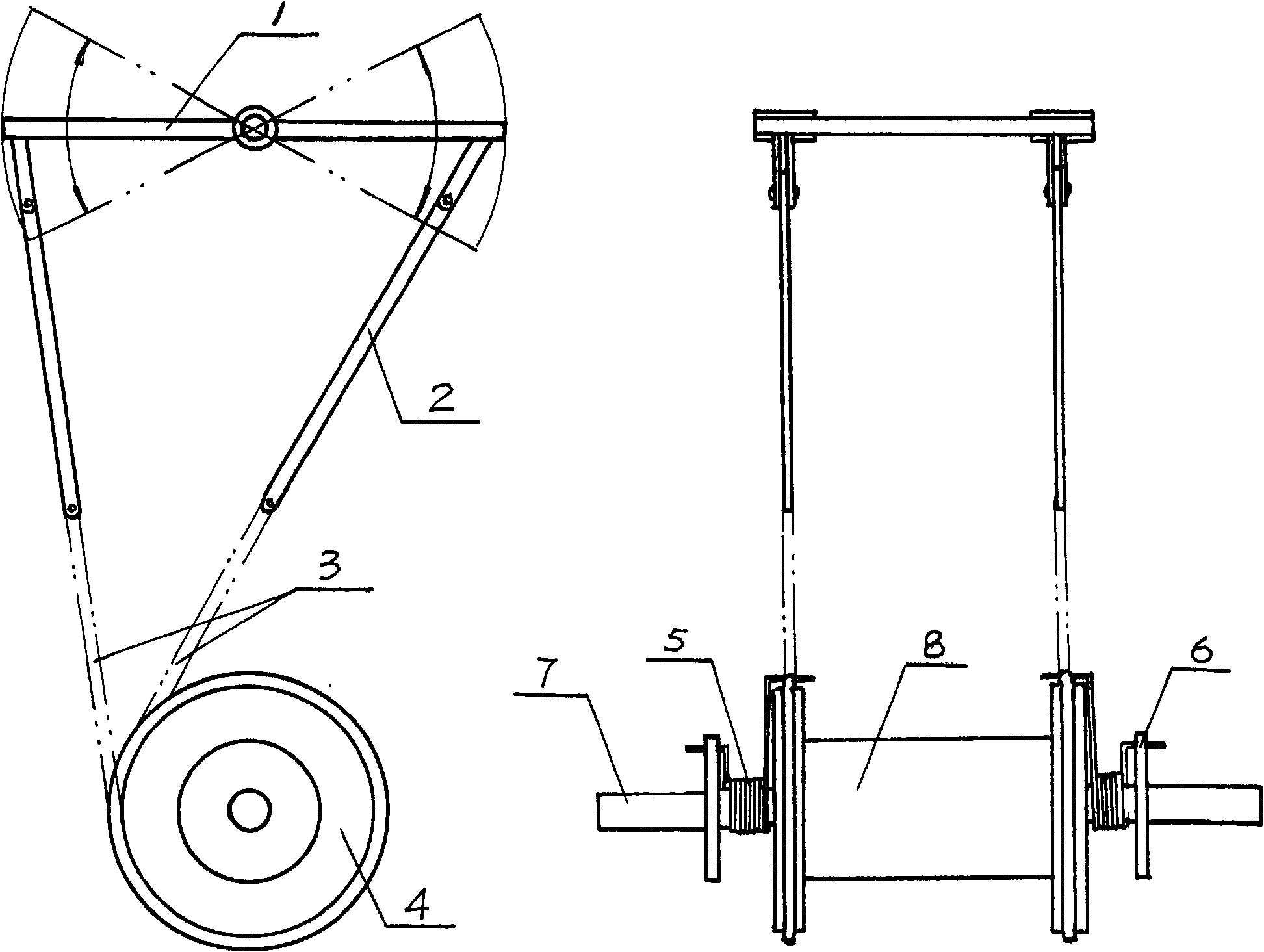

[0011] In the first embodiment of figure 1 Among them, there is a connecting rod (2) behind the pedal (1), the connecting rod (2) is connected with the chain (3), and the other end of the chain (3) is fixed on a tooth of the flywheel (4), and the two flywheels (4) fixed on the flywheel sleeve (8), the flywheel sleeve (8) is fixed on the axle (7), the axle (7) is covered with two springs (5), and one end of the spring (5) is fixed on the spring sleeve (6) , and the other end is inserted into a tooth of the flywheel (4). In this way, when the pedal (1) is pressed down, it will drive the connecting rod (2) and the chain (3) to move down, and the chain (3) will drive the flywheel (4) to rotate forward, and the flywheel (4) will drive the wheel shaft (7) to rotate At the same time, the spring (5) is tightened. When the pedal (1) reaches the limit position, under the twisting of the spring (5), the flywheel (4) is idling negatively, and the chain (3) is wound back to the flywheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com