Auxiliary start device

A starting device and grinding machine technology, applied in the direction of grinding drive device, transmission device control, grinding machine tool parts, etc., can solve the problems of enlarging the headstock of the machine tool, restricting the development of the machine tool manufacturing industry, shortening the life of the belt, etc., and achieving the goal of overcoming Large static friction and large moment of inertia ensure smooth start and large transmission torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

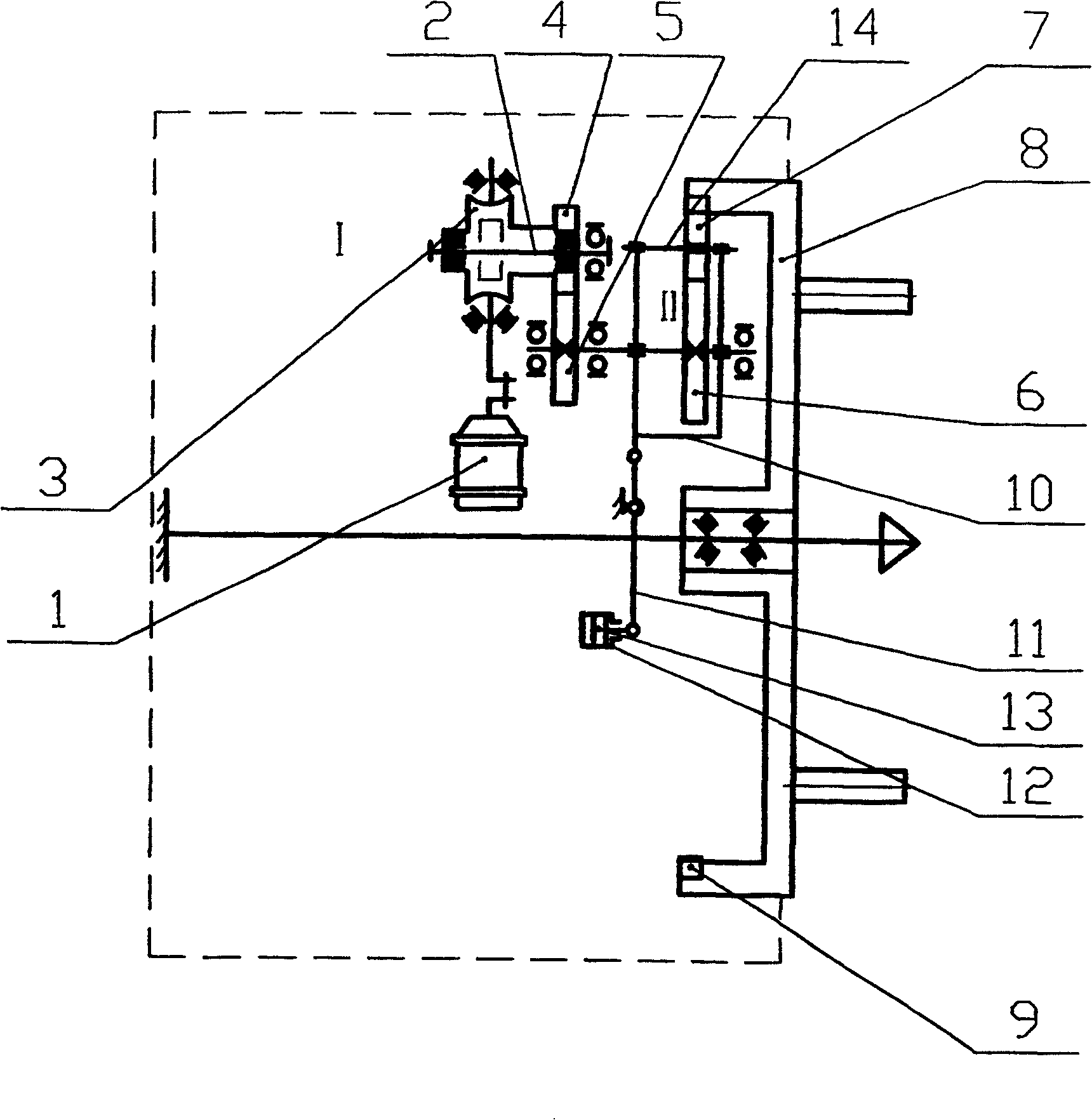

[0008] As shown in the figure: an auxiliary start-up device for a heavy-duty grinding machine, including the main drive final stage large pulley 8, it also includes a starter motor 1, a set of worm gears 3, the first pair of column gears 4, the second pair of column gears 6 and The pendulum control mechanism, the final large pulley 8 is provided with an inner ring gear 9; the output shaft of the starter motor 1 is connected to the worm, one end of the worm gear shaft 2 is connected to the first pair of column gears 4, and the driven wheel shaft 5 of the first pair of column gears 4 is connected to The second pair of column gears 6, the driven wheel 7 of the second pair of column gears 6 is used as a starting gear and the ring gear 9 can be disengaged from meshing, and the driven wheel shaft 14 of the second pair of column gears is connected with the pendulum control mechanism; the pendulum control mechanism It consists of a pendulum 10, a lever 11 and a piston cylinder 12. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com