Liquid crystal display with transparent conductive film on coated formed sandwich insulation film

A liquid crystal display, transparent conductive film technology, applied in static indicators, instruments, nonlinear optics, etc., can solve problems such as total resistance change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

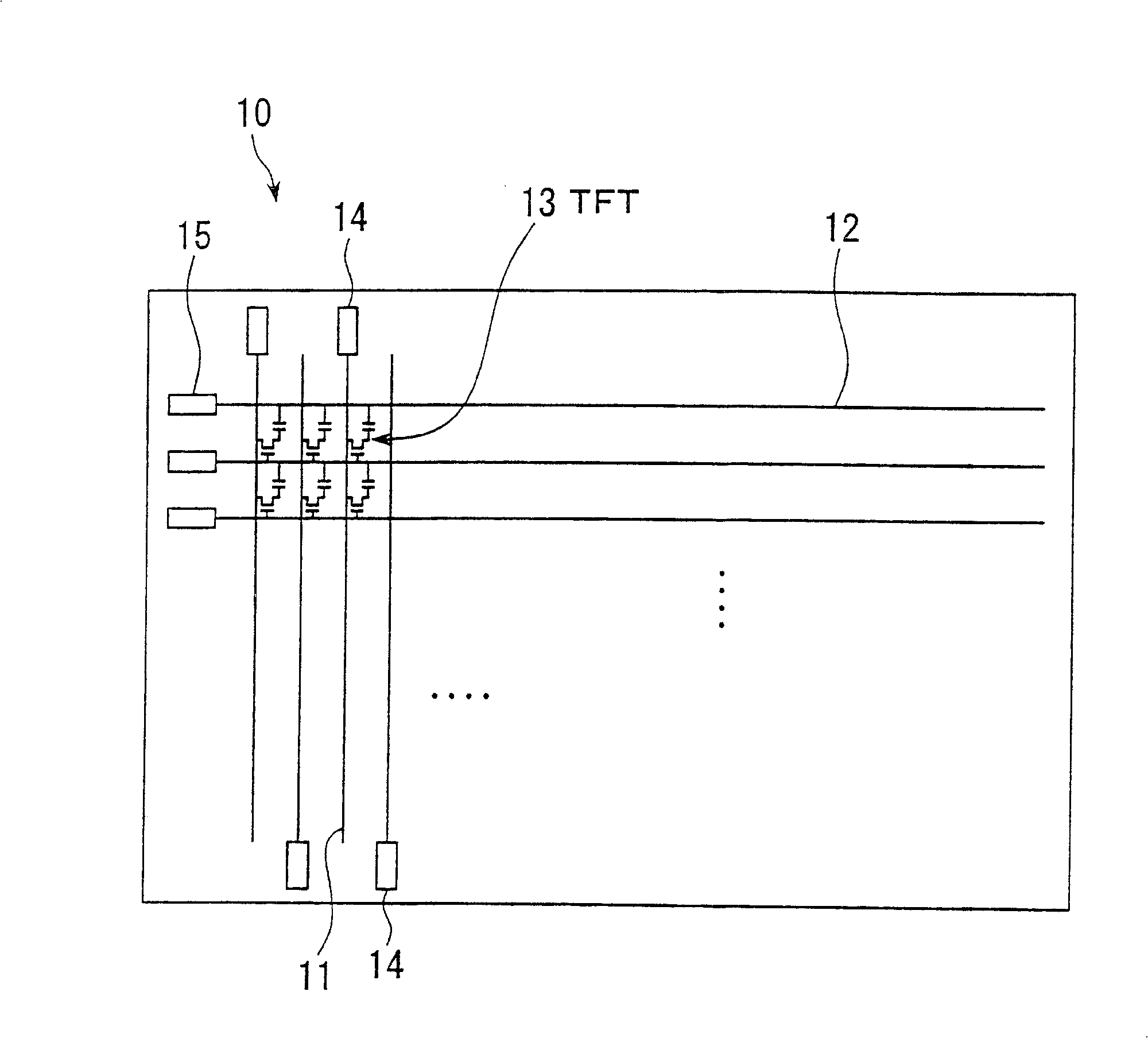

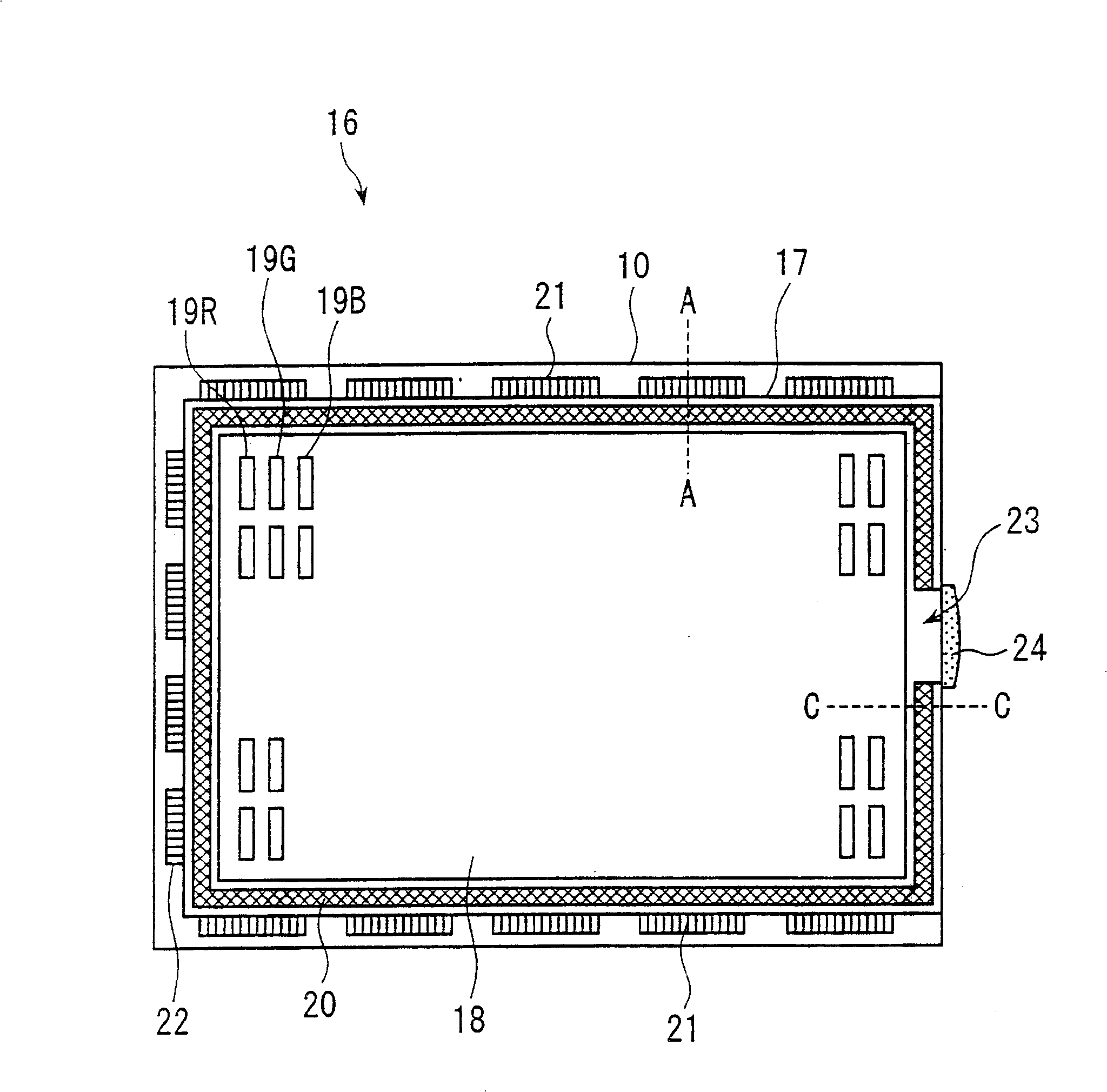

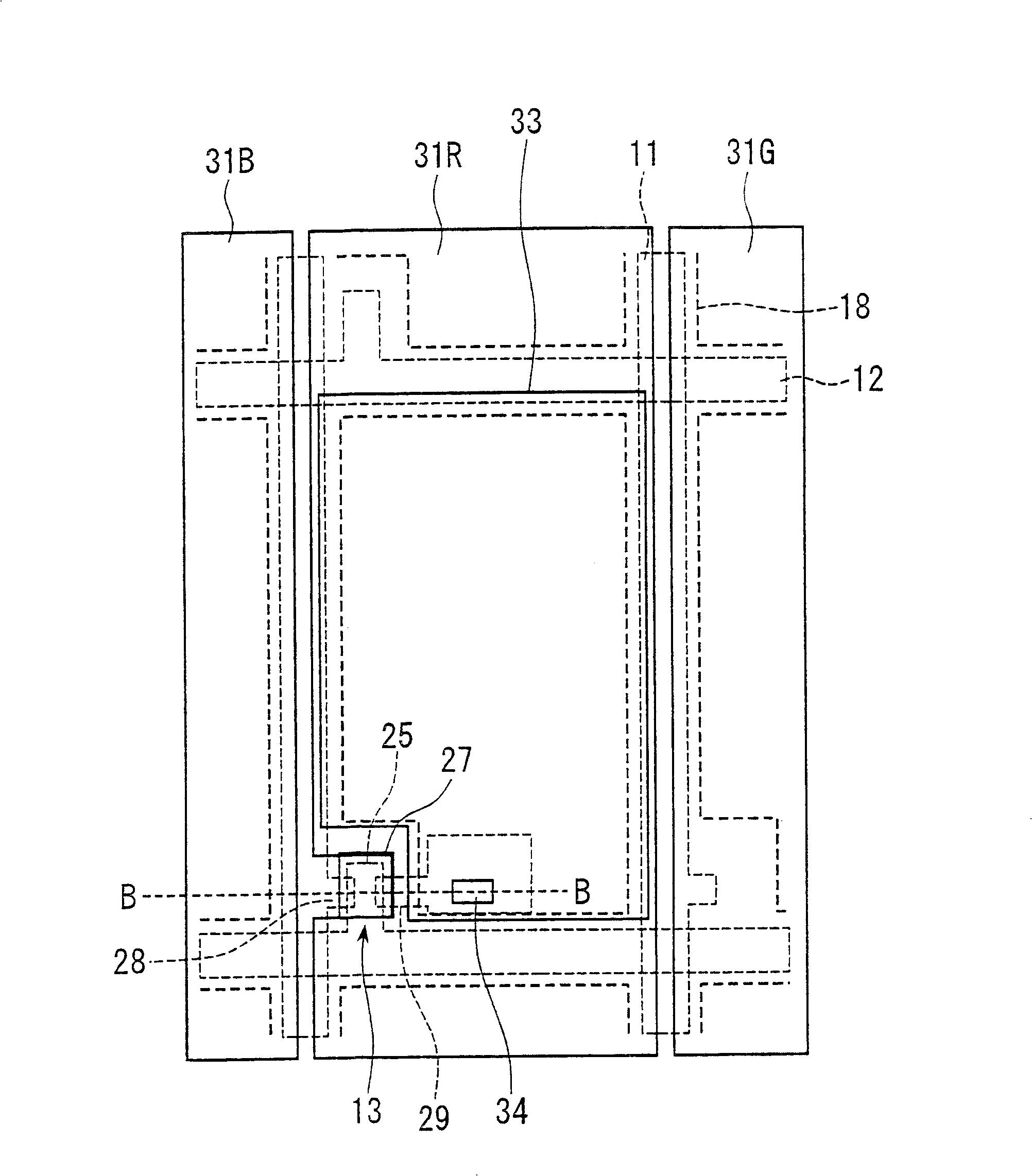

[0071] figure 1 It is a schematic plan view describing the TFT substrate structure of the transmissive liquid crystal display according to the first embodiment of the present invention. Make figure 1 The TFT substrate 10 shown in FIG. 1 and the opposing substrate 17 mentioned later face each other, and a liquid crystal material is filled in the space between the TFT substrate 10 and the opposing substrate 17 to form a liquid crystal display of a liquid crystal display. Board (see figure 2 with Figure 4 ).

[0072] On the surface of the TFT substrate 10 facing the opposite substrate 17 side, a plurality of signal lines 11 and a plurality of scanning lines 12 intersecting the signal lines 11 are provided in a grid shape. In the vicinity of each intersection of one of the signal lines 11 and one of the scanning lines 12, a TFT 13 is formed. Therefore, the TFT 13 is arranged in a matrix.

[0073] In this embodiment, the TFT13 constitutes a high-resolution liquid crystal display p...

no. 2 example

[0117] Picture 10 It is a schematic plan view describing the structure of the TFT substrate 50 in the transmissive liquid crystal display according to the second embodiment of the present invention. Such as Picture 10 As shown, on the surface of the TFT substrate 50 on the opposite substrate side not shown in the drawings, a plurality of signal lines 11 and a plurality of scanning lines 12 intersecting the signal lines 11 are arranged in a grid-like arrangement. . In the vicinity of the intersection of one of the signal lines 11 and one of the scanning lines 12, a TFT 13 is formed. Thus, the TFTs 13 are arranged in a matrix.

[0118] A common wiring conductor, that is, a common wiring 51 is also provided between adjacent scan lines 12. In the common storage type liquid crystal display, the common wiring conductor 51 and the pixel electrode form a storage capacitor.

[0119] The common wiring conductors 51 are coupled to each other, and a common potential is applied thereto. So,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com