Connector

A technology for connectors and connection objects, which is applied in the direction of connection, electrical components, coupling devices, etc., can solve the problems of low height, small displacement of the first contact part 301 and the second contact part 302, and no contact pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

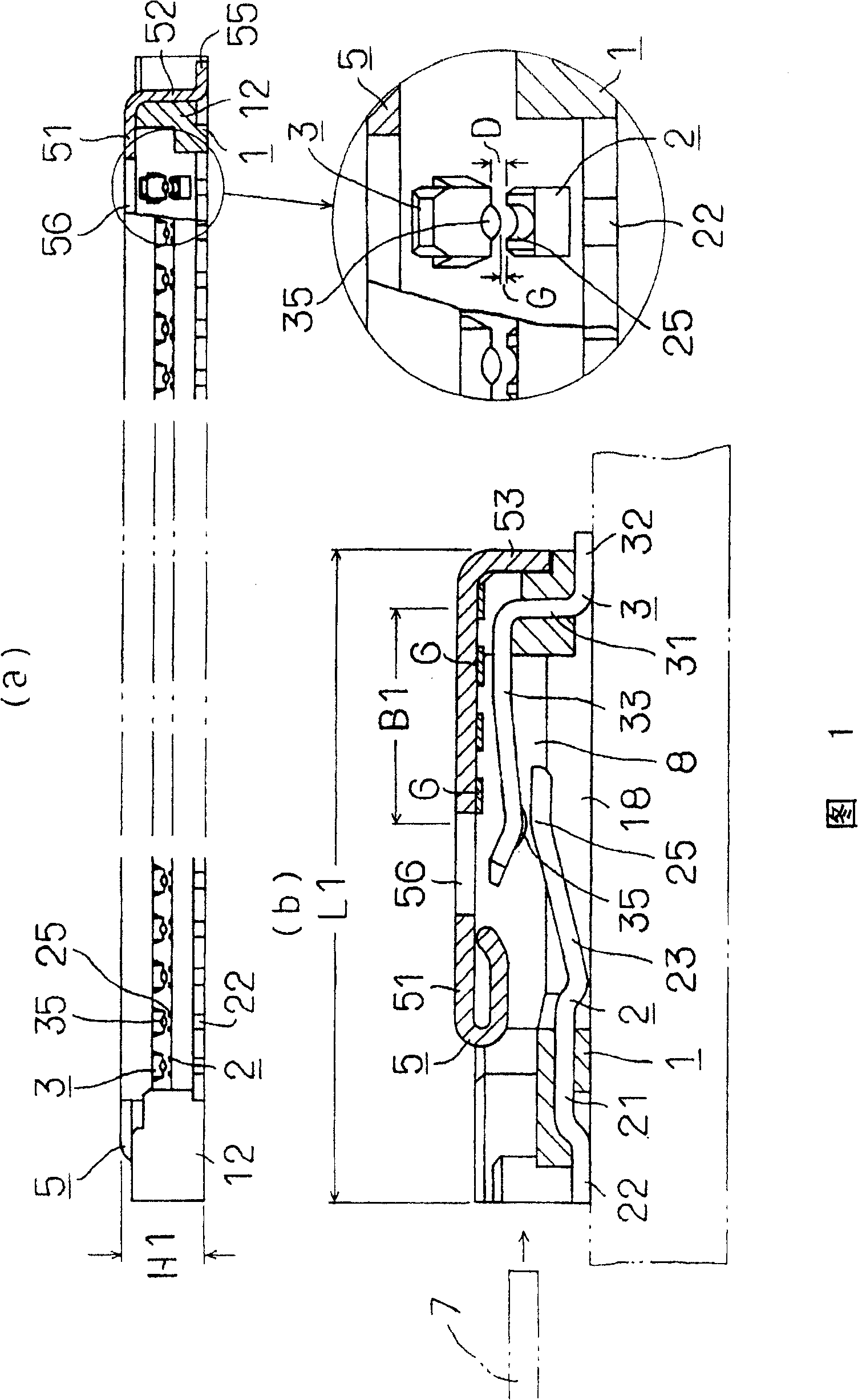

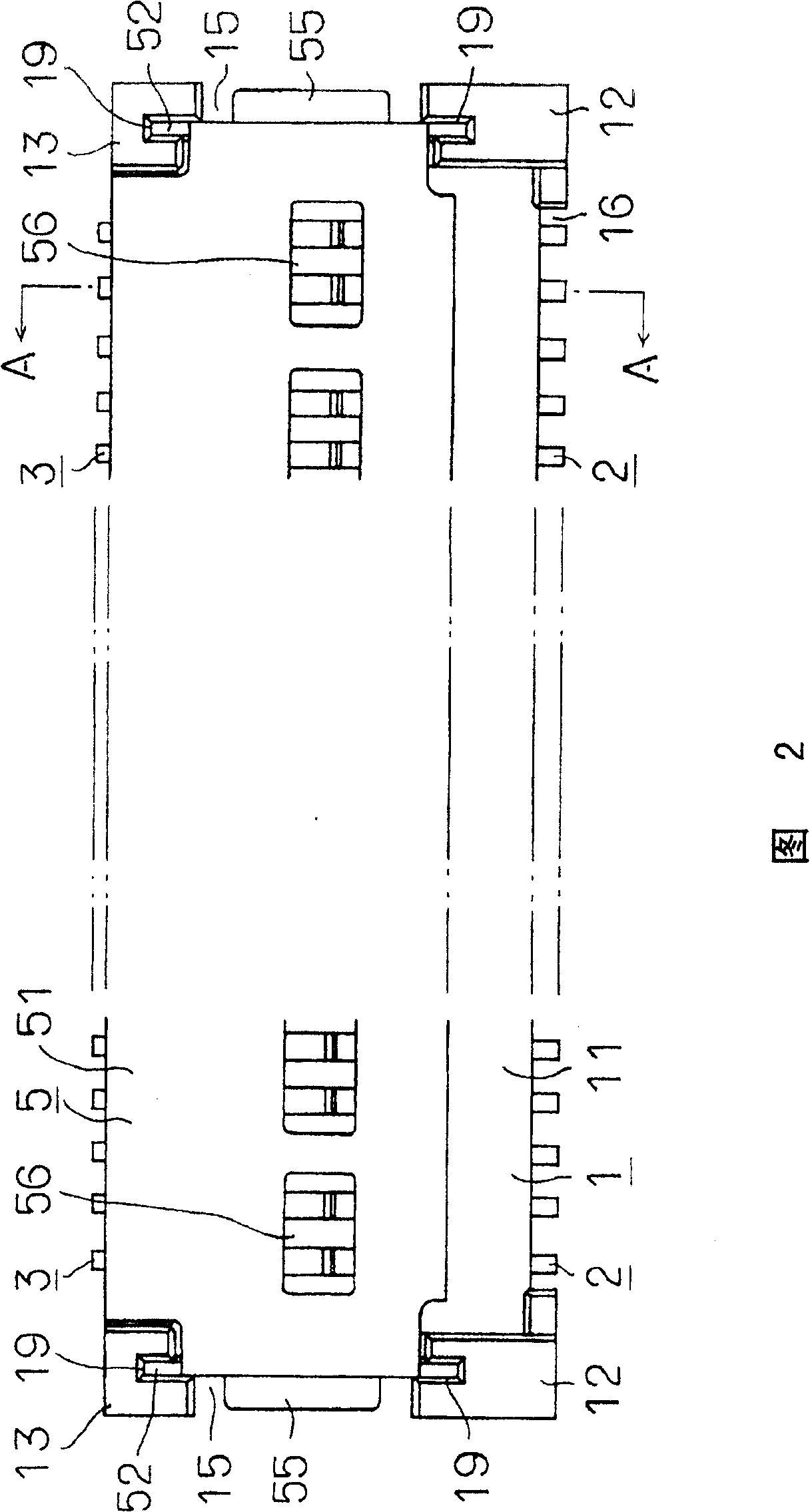

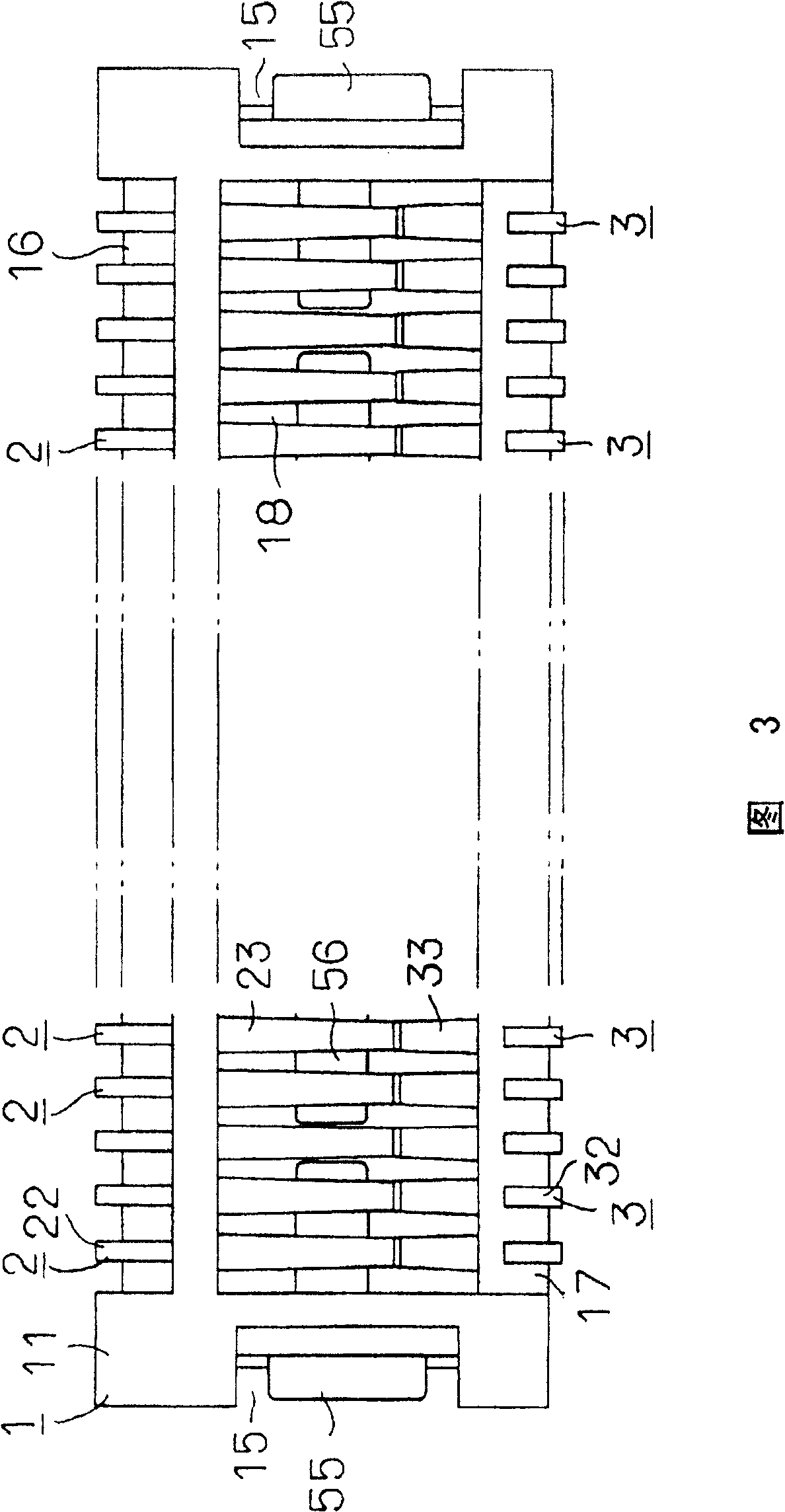

[0050] 1 to 7 show one embodiment of the connector of the present invention, that is, a connector for a flexible substrate. Contacts, 5 refer to shield fittings, 6 to 6 refer to insulating tapes, and 7 refer to FPC as an example of a flexible substrate.

[0051] The first contacts 2-2 and the second contacts 3-3 are insert-molded together with the housing 1, as shown in Figures 1 to 3, the first contacts 2 and the second contacts 3 form a group The multi-group configuration is arranged at predetermined intervals in the longitudinal direction of the housing 1 and fixed on the housing 1 .

[0052] A substrate insertion recess 8 for inserting the FPC 7 is formed between the housing 1 and the shield fitting 5 .

[0053] The casing 1 has: a base portion 11 integrally formed of an insulating synthetic resin such as LCP resin, and formed in a substantially rectangular plate shape; The two ends (the near front side of FIG. 2 ) are integrally erected, and are roughly prism-shaped; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com