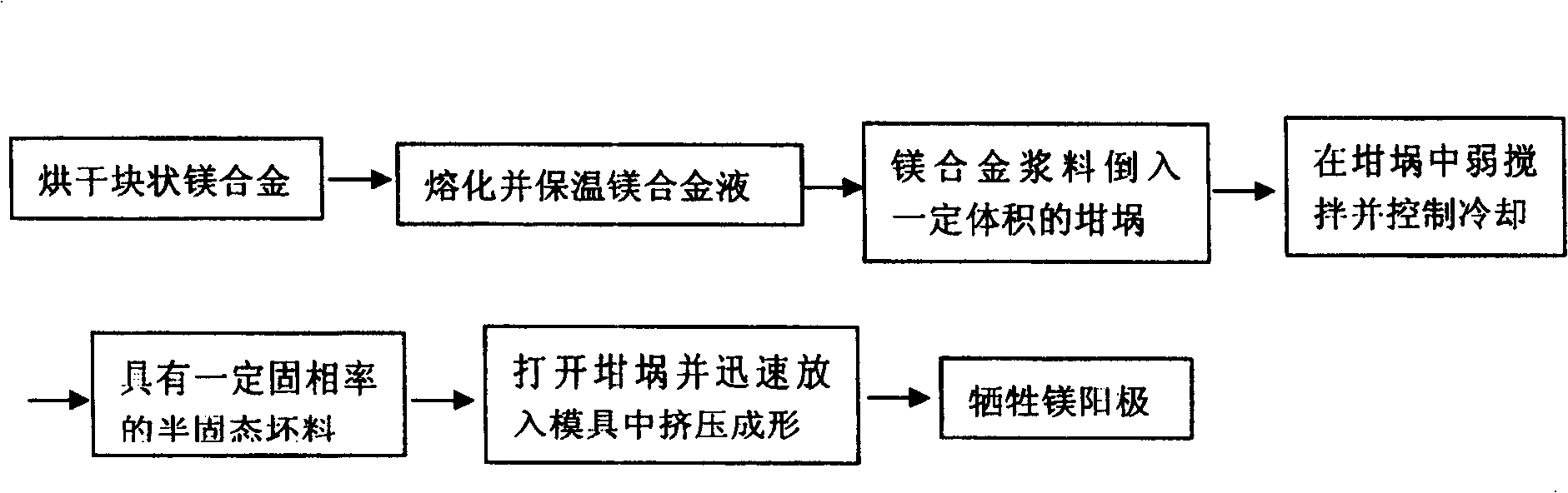

Manufacturing process for rheologic extrusion molding of sacrificial magnesium anode and device thereof

A preparation process and extrusion forming technology, which is applied in the field of rheological extrusion forming preparation technology and its devices, can solve the problems of rapid quantitative transportation of semi-solid slurry and the docking of forming equipment has not been well solved, and can expand manufacturing methods. , The effect of simple installation and low cost investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] (1) Preparation of AZ31 magnesium alloy slurry

[0038] Preparation of AZ31 magnesium alloy semi-solid billet with uniform composition, microstructure and performance, round and fine particles is the prerequisite for rheoextrusion forming sacrificial magnesium anode. The invention uses a resistance furnace to heat the dry-processed bulk commercial AZ31 magnesium alloy ingot, uses argon as a protective gas, and uses a foaming magnesium alloy covering agent to protect the molten magnesium alloy liquid. After reaching the complete melting temperature of 632°C, keep the temperature for 30 minutes.

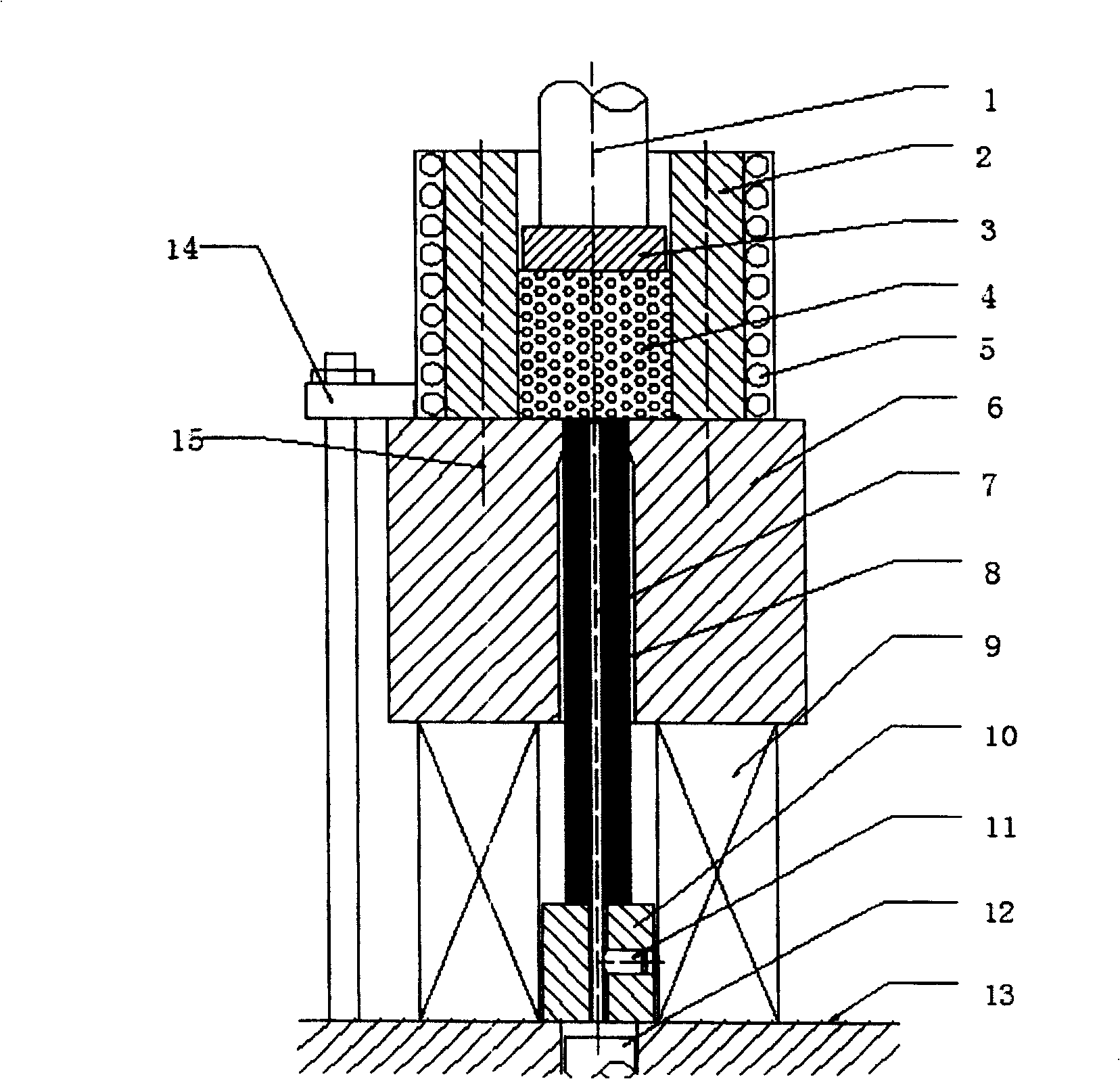

[0039] (2) Device design for rapid quantitative delivery of semi-solid slurry

[0040] Design and process a stainless steel crucible that can be opened in half. The volume of the crucible is equal to the volume of the magnesium anode. Two pairs of half-open crucibles are respectively fixed on both sides of a clamp that is convenient for manual operation, which can solve the pr...

Embodiment 1

[0048] Now the rheological extrusion diameter is ( ), AZ31 sacrificial magnesium anode with a length of 100mm is taken as an example to illustrate its production process. The inner core material is Q235C low carbon steel, the diameter size is ( ). First, the block commercial AZ31 magnesium alloy ingot that has been dried (dried at 100°C) is heated and melted in a resistance furnace, and argon is used as a protective gas at the same time, and the molten magnesium alloy liquid is protected by a foamed magnesium alloy covering agent. After reaching the complete melting temperature of 632°C, keep the temperature for 30 minutes. Design and process a stainless steel crucible for storing magnesium alloy liquid, which can be divided into two parts, and its volume is equal to the volume of the produced magnesium anode. In order to ensure uniform heat dissipation of the slurry, the inner diameter of the stainless steel crucible is approximately equal to its depth. Fix (weld) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com