Semisolid rheological forming technique method for forming high-performance three-dimensional variable section high-temperature structural parts

A semi-solid rheological and structural parts technology, applied in the field of semi-solid forming, can solve the problems of high production cost, high energy consumption, pores, segregation, bubbles and other defects that are difficult to eliminate, and achieve high production cost, long process flow, and convenient The effect of smooth separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

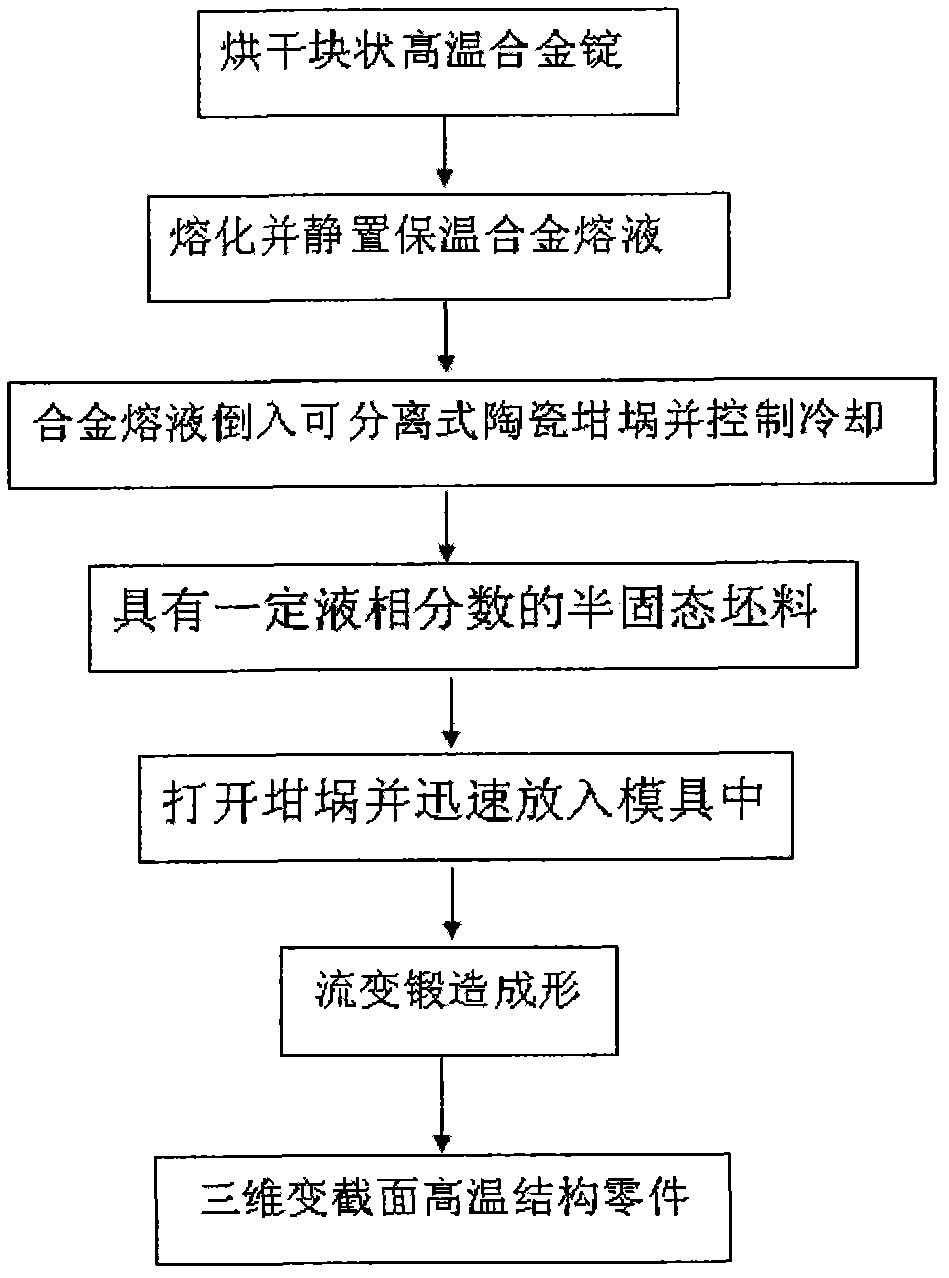

[0025] ① Preparation of semi-solid slurry

[0026] In order to realize semi-solid rheological forming, the preparation of semi-solid slurry with uniform composition, structure and performance and round and fine solid particles is the prerequisite. First use a resistance furnace to heat the dried blocky commercial high-temperature alloy ingot. To prevent oxidation, use argon as a protective gas. After reaching the complete melting temperature, keep it warm for 10-20 minutes.

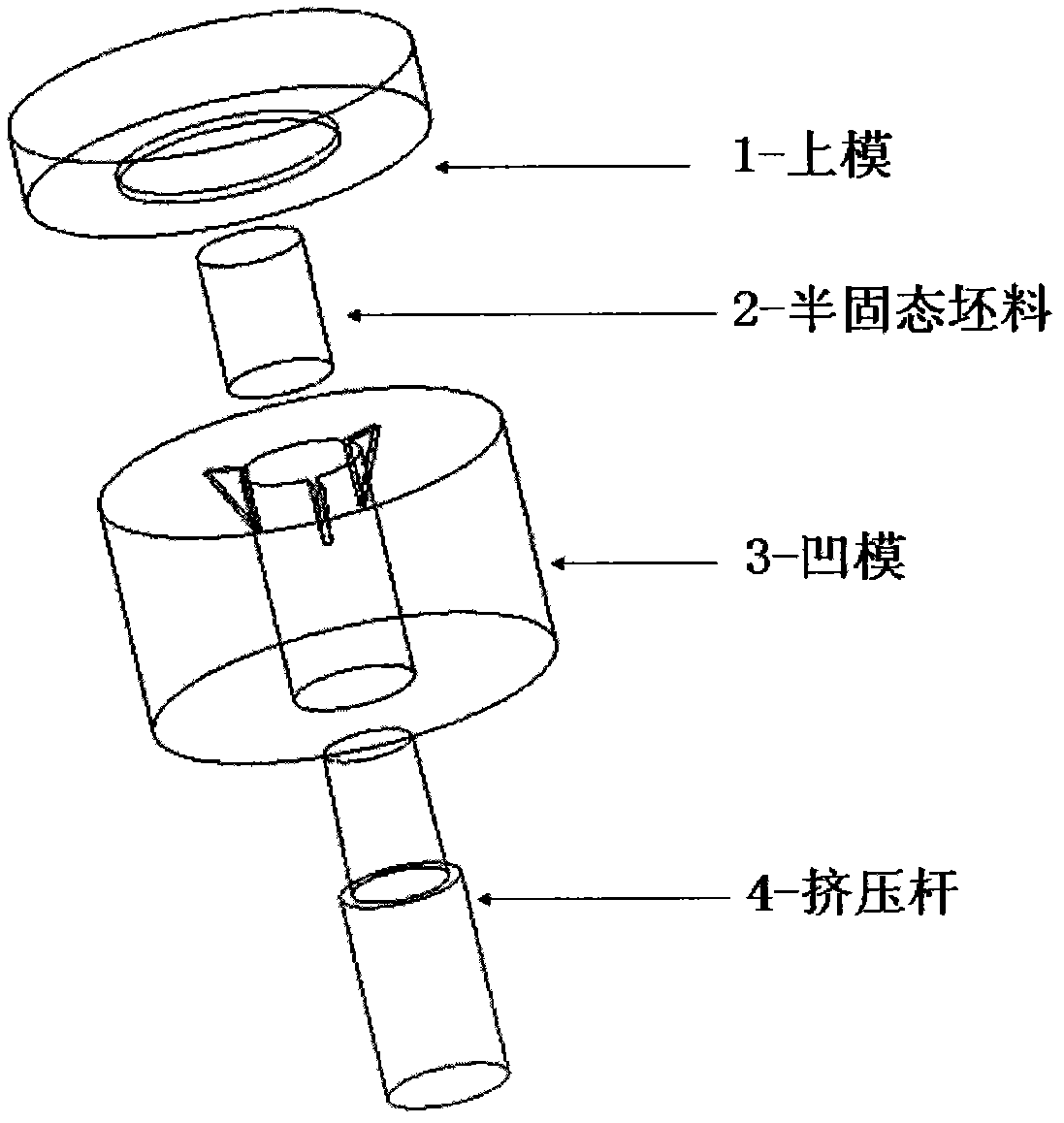

[0027] ②Design of fast quantitative delivery device for semi-solid slurry

[0028] Design and process a ceramic crucible that can be half-opened. The volume of the crucible is equal to the volume of the target part. Two pairs of half-open ceramic crucibles are respectively fixed on both sides of a clamp that is convenient for manual operation, which can solve the rapid and quantitative delivery of slurry, and also facilitate the smooth separation of semi-solid blanks and crucibles, and facilitate the cru...

Embodiment 1

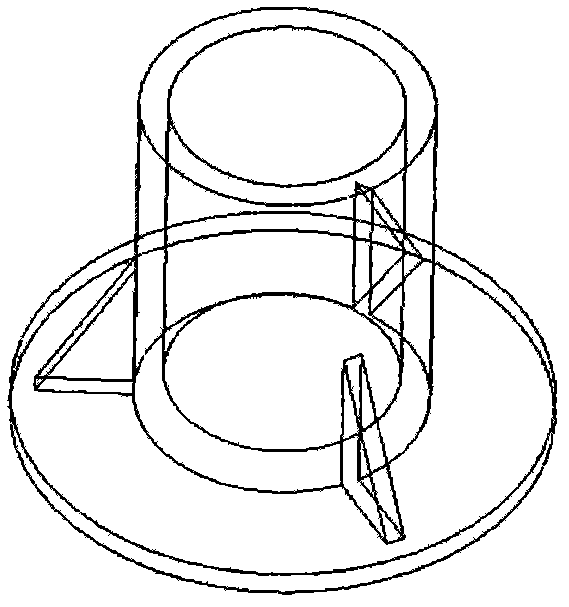

[0036] Using 718 superalloy for semi-solid rheological forging to form the three-dimensional variable cross-section structural parts in Figure-1

[0037] Firstly, heat and melt the massive commercial 718 superalloy ingot that has been dried (dried at 100° C.) in a resistance furnace, and after it is completely melted in the high temperature resistance furnace, keep it for 12 minutes. Design and process a split-type ceramic crucible for storing superalloy slurry, whose volume is equal to that of the target part. In order to ensure uniform heat dissipation of the slurry, the inner diameter of the ceramic crucible is approximately equal to its depth. Fix the two halves of the split crucible on both sides of a clamp that is convenient for manual operation, and use an electric heating device to preheat the crucible to 350 °C. After the superalloy melt was poured into the crucible and controlled to cool for 5 seconds, the crucible was opened, and the semi-solid billet was quickly p...

Embodiment 2

[0039] Using 718 superalloy for semi-solid rheological forging to form the three-dimensional variable cross-section structural parts in Figure-1

[0040] First, heat and melt the block commercial 718 superalloy ingot that has been dried (dried at 100° C.) in a resistance furnace. After melting completely in the high-temperature resistance furnace, keep it warm for 15 minutes. Design and process a split-type ceramic crucible for storing superalloy slurry, whose volume is equal to that of the target part. In order to ensure uniform heat dissipation of the slurry, the inner diameter of the ceramic crucible is approximately equal to its depth. Fix the two halves of the split crucible on both sides of a clamp that is convenient for manual operation, and use an electric heating device to preheat the crucible to 370°C. After the superalloy melt was poured into the crucible and controlled to cool for 7 seconds, the crucible was opened, and the semi-solid billet was quickly poured fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com