A method of electronic shell package for preparing SiC particle reinforced composite material by using a semi-solid-state technology

An electronic packaging and particle reinforcement technology, which is applied in the field of preparing SiC particle reinforced composite electronic packaging shell technology, can solve the problems of long processing routes and high production costs, and achieve the effects of reducing energy consumption, improving product quality, and expanding application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

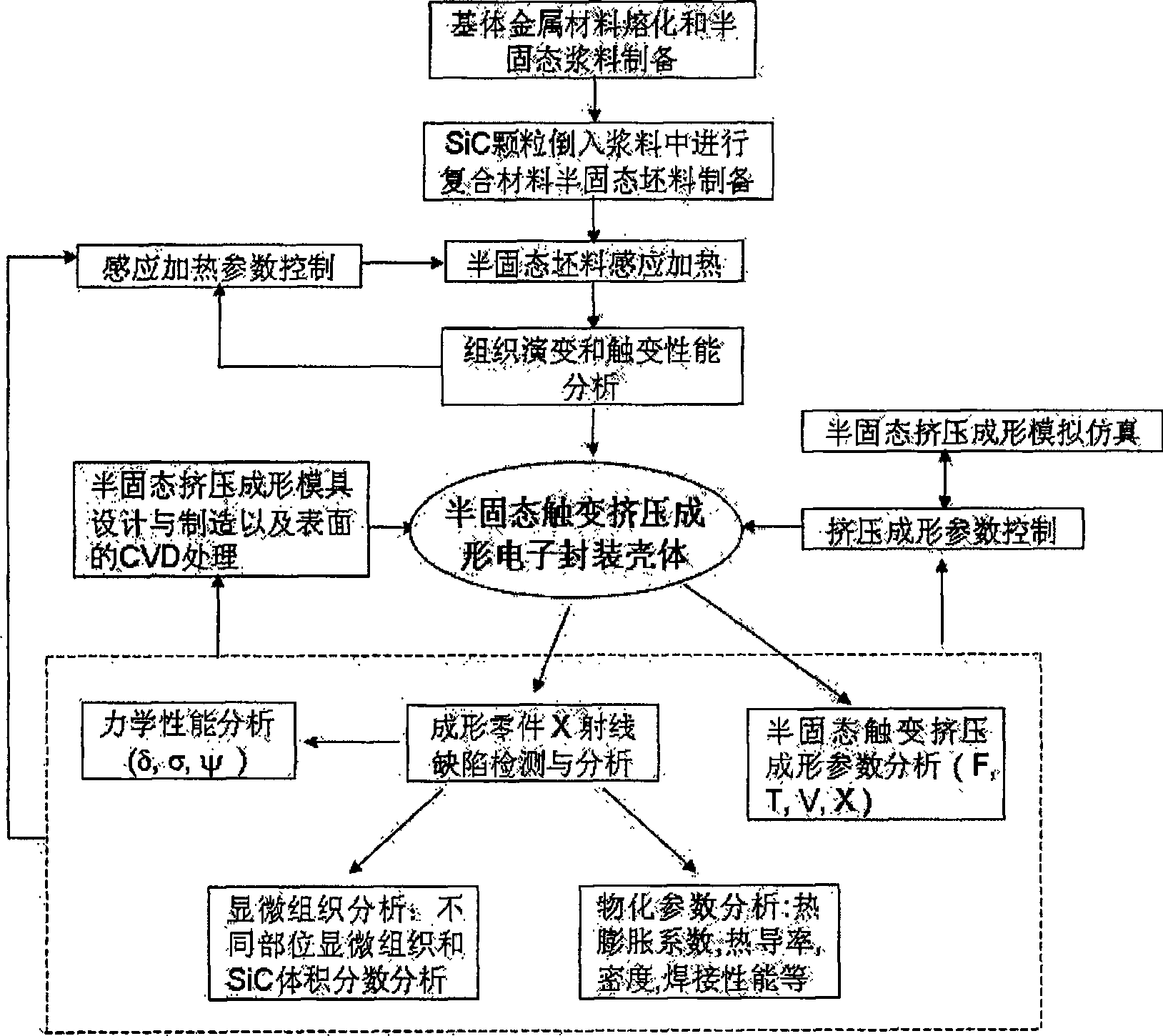

Method used

Image

Examples

Embodiment 1

[0027] Example 1: A semi-solid thixotropic extrusion molding method was used to prepare SiC particle-reinforced A356 aluminum alloy composite electronic packaging shell parts.

[0028] SiC particle (20% volume fraction) reinforced A356 aluminum alloy composite material with a diameter of φ56mm was purchased from Duralcan company (Duralcan company). After distance cutting, the billet is firstly heated rapidly and uniformly to the semi-solid temperature: 580°C with an induction heating furnace. Designing a mold for back-extruding a cup-shaped piece, and processing a forming cavity for an electronic package housing in the horizontal direction at the bottom edge of the die cavity. The heated semi-solid billet is quickly put into the die of the extrusion die with a clamp (the preheating temperature of the die is set to 200° C.). The extrusion speed of the press is adjusted to 120mm / s, a graphite release agent is used, the forming pressure is set to 600KN, and the holding time is s...

Embodiment 2

[0029] Example 2: SiC particles reinforced A356 aluminum alloy composite material electronic package casing parts were prepared by semi-solid rheological extrusion molding method.

[0030] After drying the bulk base metal aluminum alloy A356 at 100°C, it was heated and melted in a resistance furnace. The melting temperature was set at 640° C., and the alloy was kept for 30 minutes after it was completely melted. Add fine SiC particles with a volume fraction of 25% to the alloy liquid after heat preservation and standing. In order to prevent the aggregation of SiC particles, it should be added gradually in several times during the adding process, and sprinkled on the surface of the molten metal, stirring evenly while adding, and controlling the cooling to a semi-solid temperature of 579°C. Designing a mold for back-extruding a cup-shaped piece, and processing a forming cavity for an electronic package housing in the horizontal direction at the bottom edge of the die cavity. T...

Embodiment 3

[0031] Example 3: SiC particle-reinforced brass alloy CuZn31Al2 composite material electronic package shell parts were prepared by semi-solid rheological extrusion molding method.

[0032] After the bulk matrix metal brass alloy CuZn31Al2 is dried at 100°C, it is heated and melted in a resistance furnace. The melting temperature was set at 970°C, and the alloy was kept for 30 minutes after it was completely melted. Add fine SiC particles with a volume fraction of 26% to the alloy liquid after heat preservation and standing. In order to prevent the aggregation of SiC particles, it should be added gradually in several times during the adding process, and sprinkled on the surface of the molten metal, stirring evenly while adding, and controlling the cooling to a semi-solid temperature of 960°C. Designing a mold for back-extruding a cup-shaped piece, and processing a forming cavity for an electronic package housing in the horizontal direction at the bottom edge of the die cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com