Process used for spray forming Si-Al alloy solid-liquid two-phase region hot working molding encapsulating parts

A thermal forming and spray forming technology, applied in metal processing equipment, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of low material utilization rate, high production cost, long processing route, etc. Improve performance and overcome the effect of long processing routes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

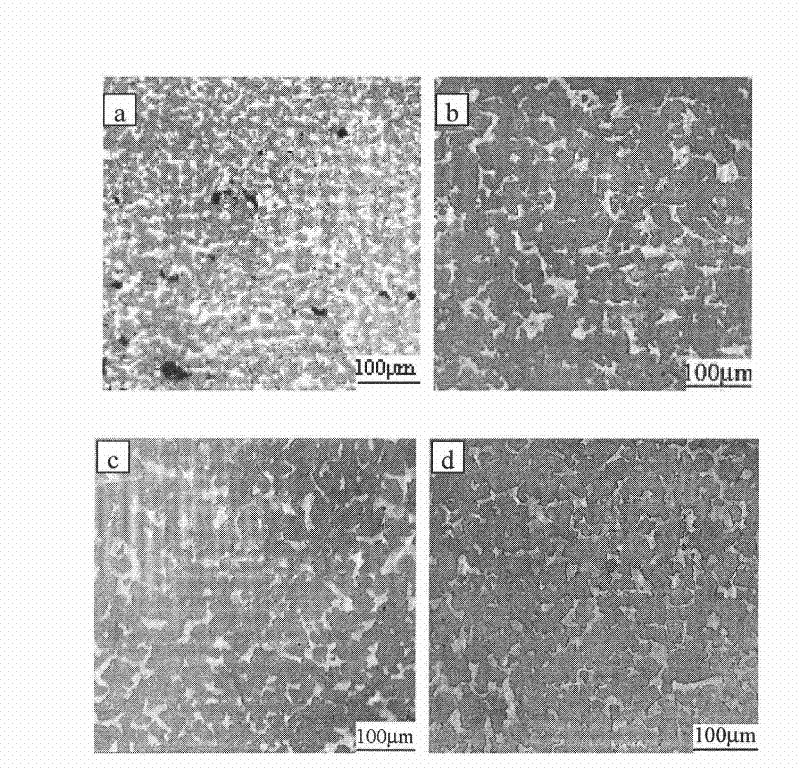

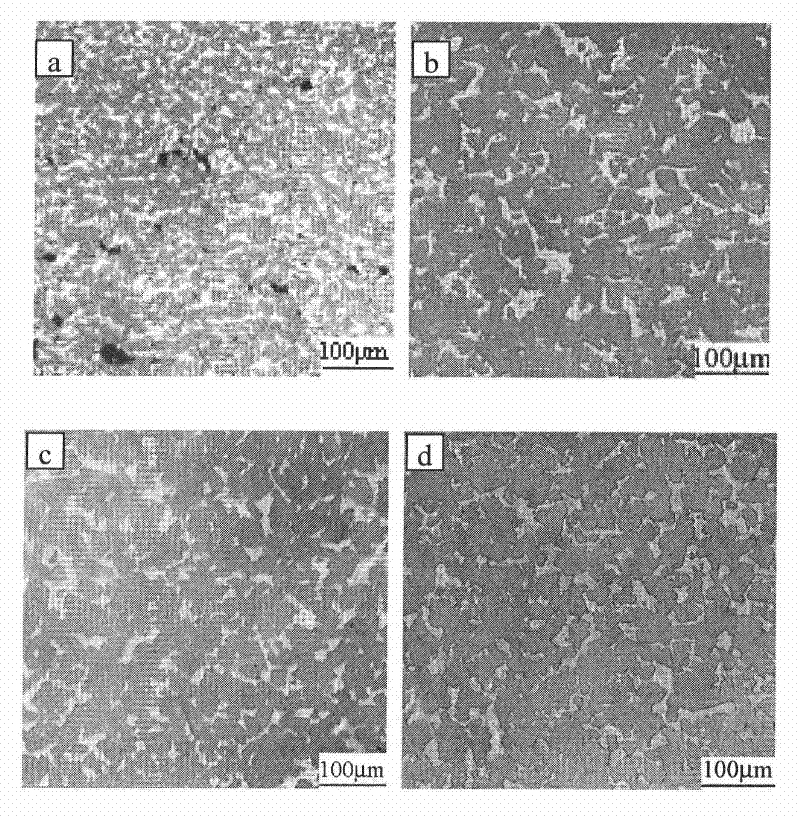

[0032] According to the mold size requirements, the 60wt% Si-Al alloy (the content of the alloy is: 60wt% Si and 40wt% Al) deposition blank prepared by spray forming is processed into the corresponding workpiece blank, 60wt% Si-Al alloy The photo of the microstructure of the deposited blank is shown in figure 1As shown in a, put the blank into the mold; place the assembled mold and workpiece together in a high-temperature hot-press furnace to heat up to 720°C, and apply a constant pressure to the mold during the heating process, and the pressure is 120MPa , heat preservation and pressure holding for 30 minutes, the mold with the workpiece is taken out of the furnace for air cooling, and after cooling, the workpiece is demoulded and the subsequent parts are finished into usable packaged parts. The microstructure of the 60wt% Si-Al alloy packaging part (made by the process of processing the solid-liquid two-phase region) of this embodiment is as follows figure 1 shown in d.

Embodiment 2

[0034] According to the mold size requirements, the prepared 60wt% Si-0.2wt% Mg-0.35wt% Mn-Al alloy (the content of this alloy is: 60wt% Si, 0.2wt% Mg, 0.35wt% Mn and 39.45wt% Al) deposition blanks are processed into corresponding workpiece blanks, and the blanks are packed into moulds; the assembled molds and workpieces are placed in a high-temperature hot-press furnace and heated to 695 ° C. During the process, a constant pressure is applied to the mold, the pressure is 150MPa, heat preservation and pressure holding for 25 minutes, the mold with the workpiece is taken out of the furnace for air cooling, and after cooling, the workpiece is demoulded and the subsequent parts are finished into usable packaged parts .

Embodiment 3

[0036] According to the mold size requirements, the 70wt% Si-0.45wt% Mg-0.15wt% Mn-0.22wt% Zr-Al prepared by spray forming (the content of the alloy is: 70wt% Si, 0.45wt% Mg, 0.15 Wt% Mn, 0.22wt% Zr and 29.18wt% Al) alloy deposition blanks are processed into corresponding workpiece blanks, and blanks are packed into moulds; the assembled molds and workpieces are placed in a high-temperature hot-press furnace Heating to 745°C, applying a constant pressure on the mold during the heating process, the pressure is 90MPa, heat preservation and pressure holding for 45min, take the mold with the workpiece out of the furnace for air cooling, and demould the workpiece after cooling And subsequent parts are finished into usable packaged parts.

[0037] figure 1 It is a microstructure comparison diagram of spray-formed 60wt% Si-Al alloy packaging parts obtained by different subsequent processing techniques. From figure 1 In a, it can be seen that the spray-formed silicon-aluminum alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com