A kind of sintered NdFeB magnet with composite film layer and its preparation method

A composite film layer, NdFeB technology, applied in the coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of poor corrosion resistance, affecting the performance of sintered NdFeB magnets, etc., to improve the durability The effect of high temperature oxidation resistance and erosion resistance, reducing the internal stress of the film layer and enhancing the bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

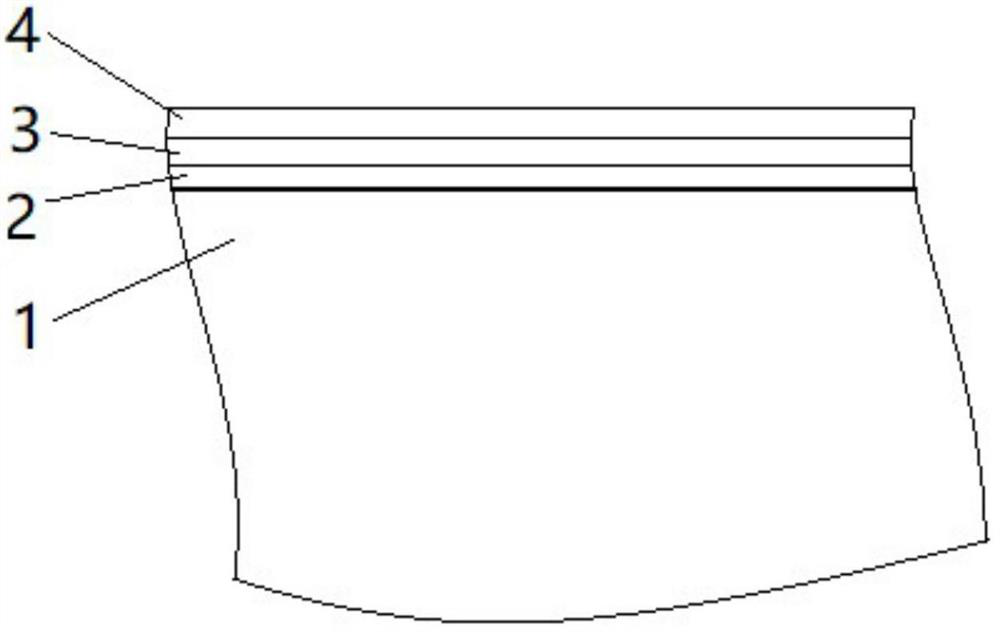

[0041] The embodiment of the present invention also provides a method for preparing a sintered NdFeB magnet with a composite film layer, which may include the following steps, see figure 1 .

[0042] s1: Grinding, polishing and cleaning the surface of the magnet body 1;

[0043] s2: An aluminum film layer 2, an aluminum oxide film layer 3 and a titanium nitride film layer 4 are sequentially deposited on the surface of the magnet body 1 by physical vapor deposition.

[0044] In step s1, grinding, polishing and cleaning the surface of the magnet body 1 can effectively remove impurities on the surface of the magnet, so that the deposited composite film can be more firmly combined with the magnet body 1 to prevent falling off and avoid The inclusion of impurities in the composite film will affect the corrosion resistance of the composite film.

[0045] In step s2, the physical vapor deposition method deposits a film layer, which has the characteristics of uniform and dense film ...

Embodiment 1

[0059] Fill the vacuum chamber with argon gas to a pressure of 0.5 Pa, energize the aluminum target, adjust the power of the aluminum target to 80W, and deposit an aluminum film layer 2 on the magnet body 1 after the pretreatment process and pre-coating treatment; The vacuum chamber is filled with argon gas to a pressure of 0.7Pa, and the radio frequency power is 250W, and the aluminum oxide film layer 3 is deposited on the aluminum film layer 2 of the magnet body 1 by radio frequency sputtering; finally, the gas in the vacuum chamber is exhausted, and the argon gas The flow rate is 30sccm and the nitrogen flow rate is 4sccm. Fill the vacuum chamber with argon and nitrogen until the vacuum chamber pressure is 0.7Pa, adjust the titanium target power to 100W, deposit a titanium nitride film layer 4 on the aluminum oxide film layer 3 of the magnet body 1, and complete Finally, turn off the power supply of the titanium target. After testing, the performance of the composite film ob...

Embodiment 2

[0061] Fill the vacuum chamber with argon gas to a pressure of 0.5Pa, energize the aluminum target, adjust the power of the aluminum target to 100W, and deposit an aluminum film layer 2 on the magnet body 1 after the pretreatment process and pre-coating treatment; The vacuum chamber is filled with argon gas to a pressure of 1.0Pa, and the radio frequency power is 350W. An aluminum oxide film layer 3 is deposited on the aluminum film layer 2 of the magnet body 1 by radio frequency sputtering; Fill the vacuum chamber with argon and nitrogen at 30sccm and nitrogen flow rate of 4sccm until the vacuum chamber pressure is 1.0Pa, adjust the titanium target power to 150W, and deposit a titanium nitride film 4 on the aluminum oxide film 3 of the magnet body 1. After completion Turn off the power supply of the titanium target. After testing, the performance of the composite film obtained under this condition is as follows: the total thickness of the film is 2.3 μm; the hardness of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com