Guide wheel charging device of electric spark wire cutting machine tool

A technology for cutting machine tools and EDM wires, which is applied in electrode manufacturing, electric processing equipment, metal processing equipment, etc. , The effect of improving processing performance and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

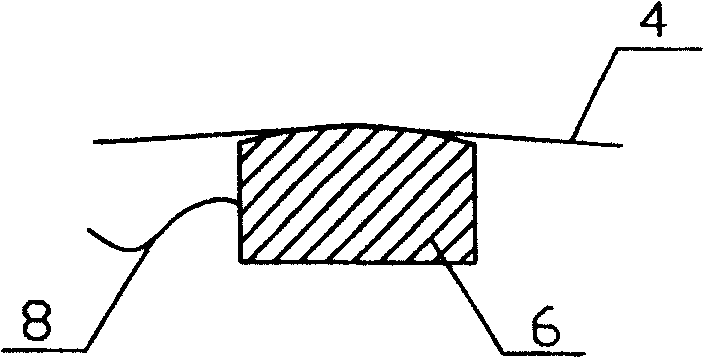

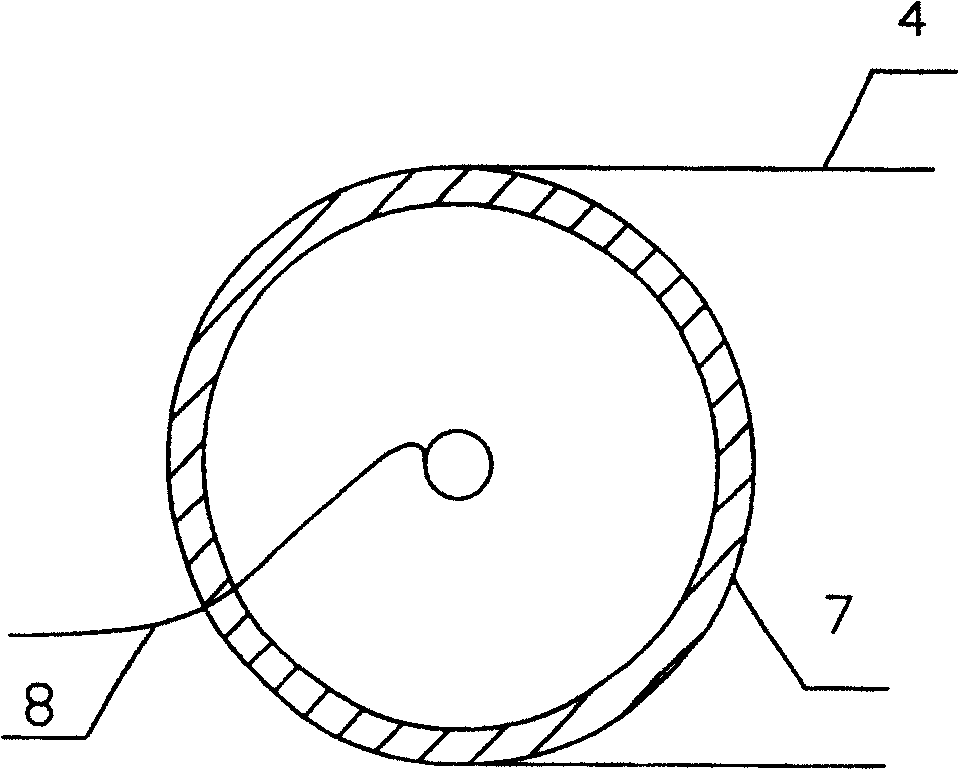

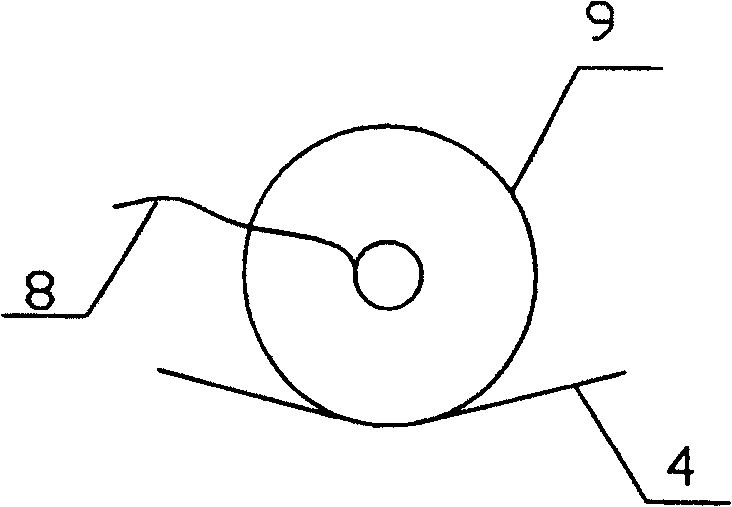

[0031] Such as Figure 4 , 5 As shown in . 32. The elastic fixing piece 33 and the static feeding body 34 are composed of the spring 32 in the cavity of the terminal body 31, the elastic fixing piece 33 is installed on the terminal body 31, the static feeding body 34 is embedded in the elastic body 32, and the feeding guide wheel 2 Both ends of the main shaft 23 are embedded with a moving electric body 21.

[0032] The main shaft of above-mentioned feeder guide wheel 2 can only be provided with above-mentioned feeder at one end, also can establish identical two sets of feeder at two ends.

[0033] The external power supply 8 is connected to the terminal main body 31 of the power-feeding terminal 3, and then passed to the dynamic power-feeding body 21 of the power-feeding guide wheel 2 through the static power-feeding body 34 on the elastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com