Making process of binaural connector for contact network

A manufacturing method and connector technology, which is applied in the manufacturing field of steel double-ear connectors, can solve problems such as difficulty in ensuring internal quality, low process yield, and impact on reliability, so as to reduce the risk of dust pollution and silicosis , smooth surface, easy to automatically control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

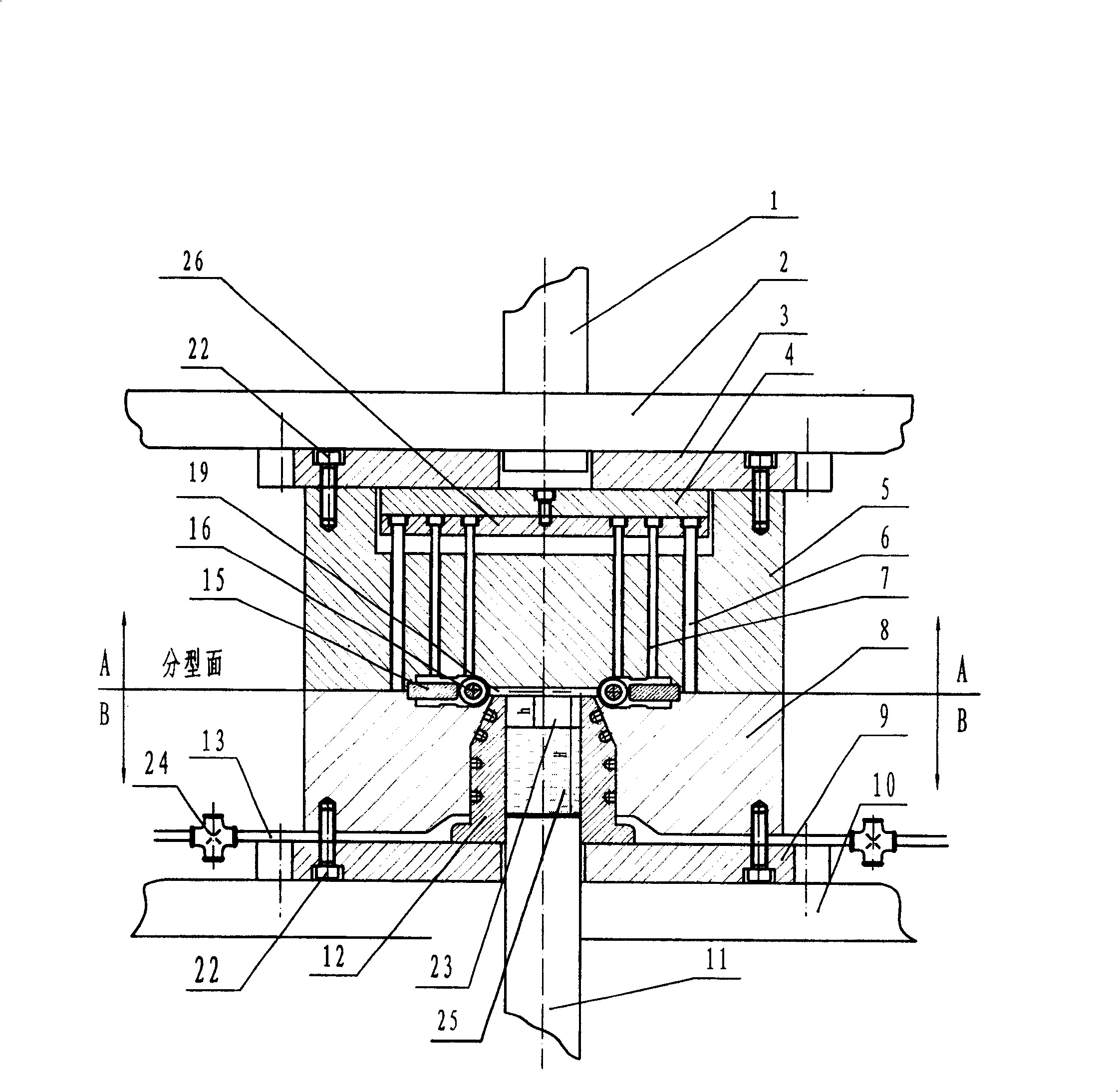

[0042] Firstly, the manufacturing mold used to realize the method is introduced.

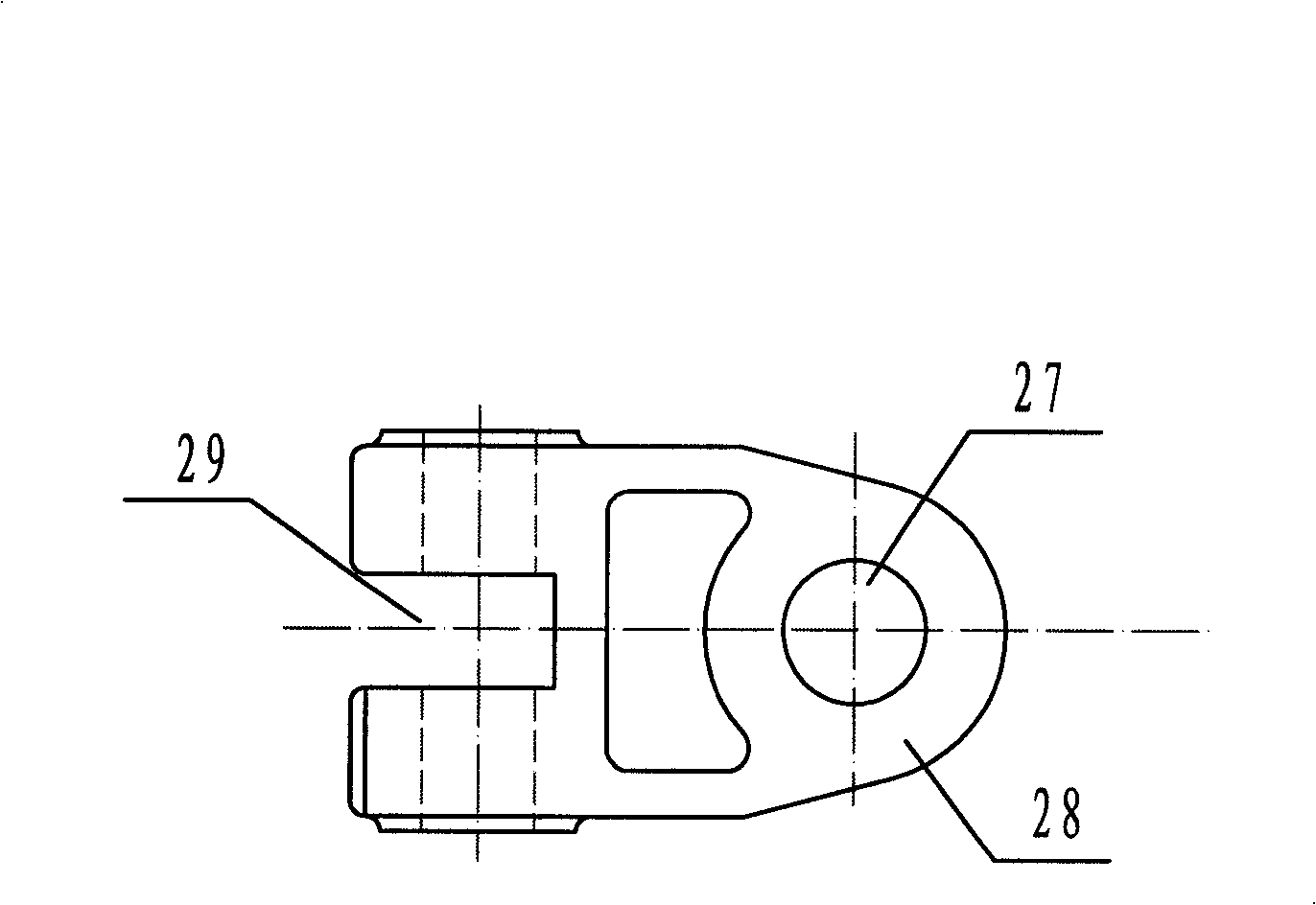

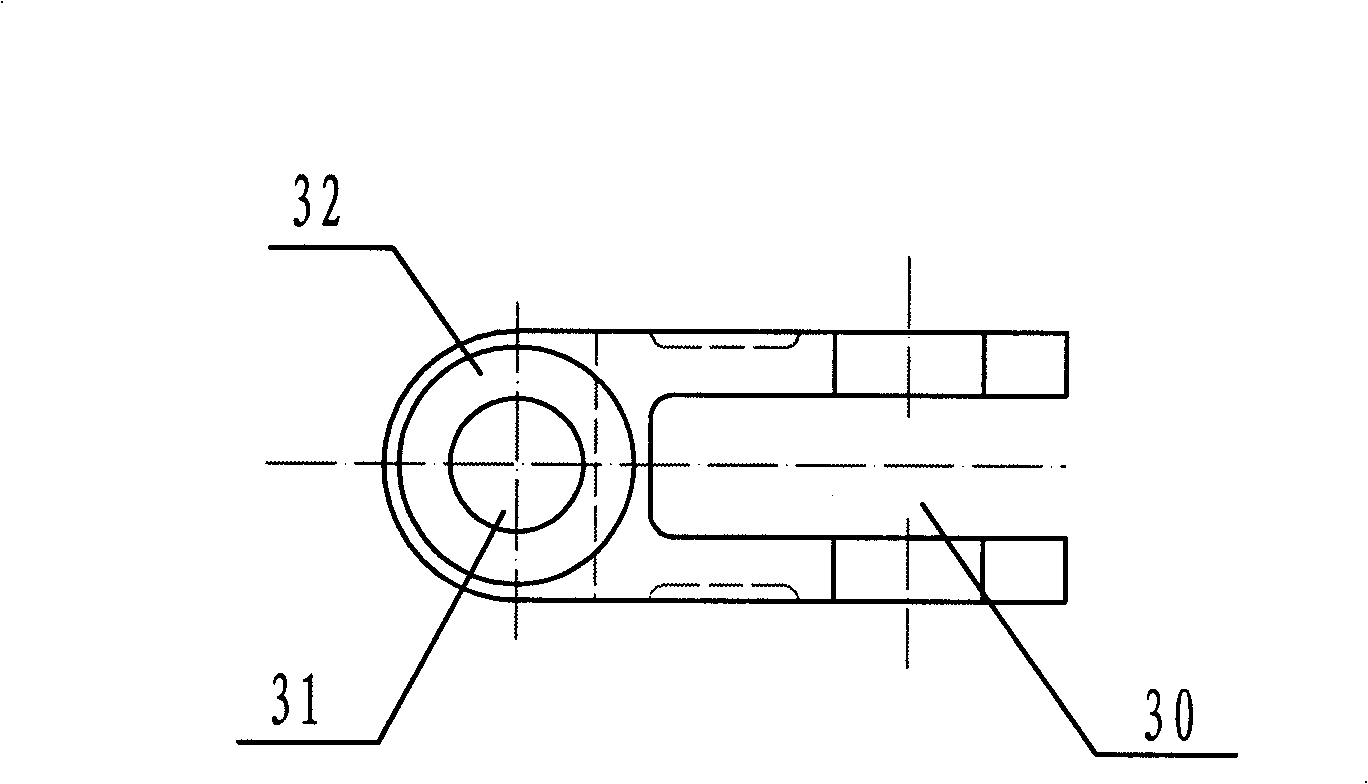

[0043] The mold in this invention includes six parts: upper mold, lower mold, punch, feeding device, side pumping device and mold temperature regulating device, see the attached Figure 3-6 . in figure 1 Parts diagram of the two-ear connector; image 3 , Figure 4 , Figure 5 , Image 6 Several views of the mold are used to better describe the manufacturing method of the catenary double lug connector.

[0044] The upper mold comprises two parts, the upper mold body 5 and the upper mold fixing plate 3 . There are 4 cavities with the same shape and size on the upper mold body 5, which form the upper half of the double ear connector. The shape is the same as that of the upper half of the double ear connector, and the dimensions in each direction are corresponding The size of the part is 1.3% larger to compensate for the size reduction caused by cooling shrinkage. A cylindrical boss 14 with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com