Carbon nanotube hydrogen-storing and coating method

A carbon nanotube, hydrogen storage technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problem of inability to solve the problem of hydrogen energy storage, inability to accurately calculate the amount of hydrogen adsorbed by carbon nanotubes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

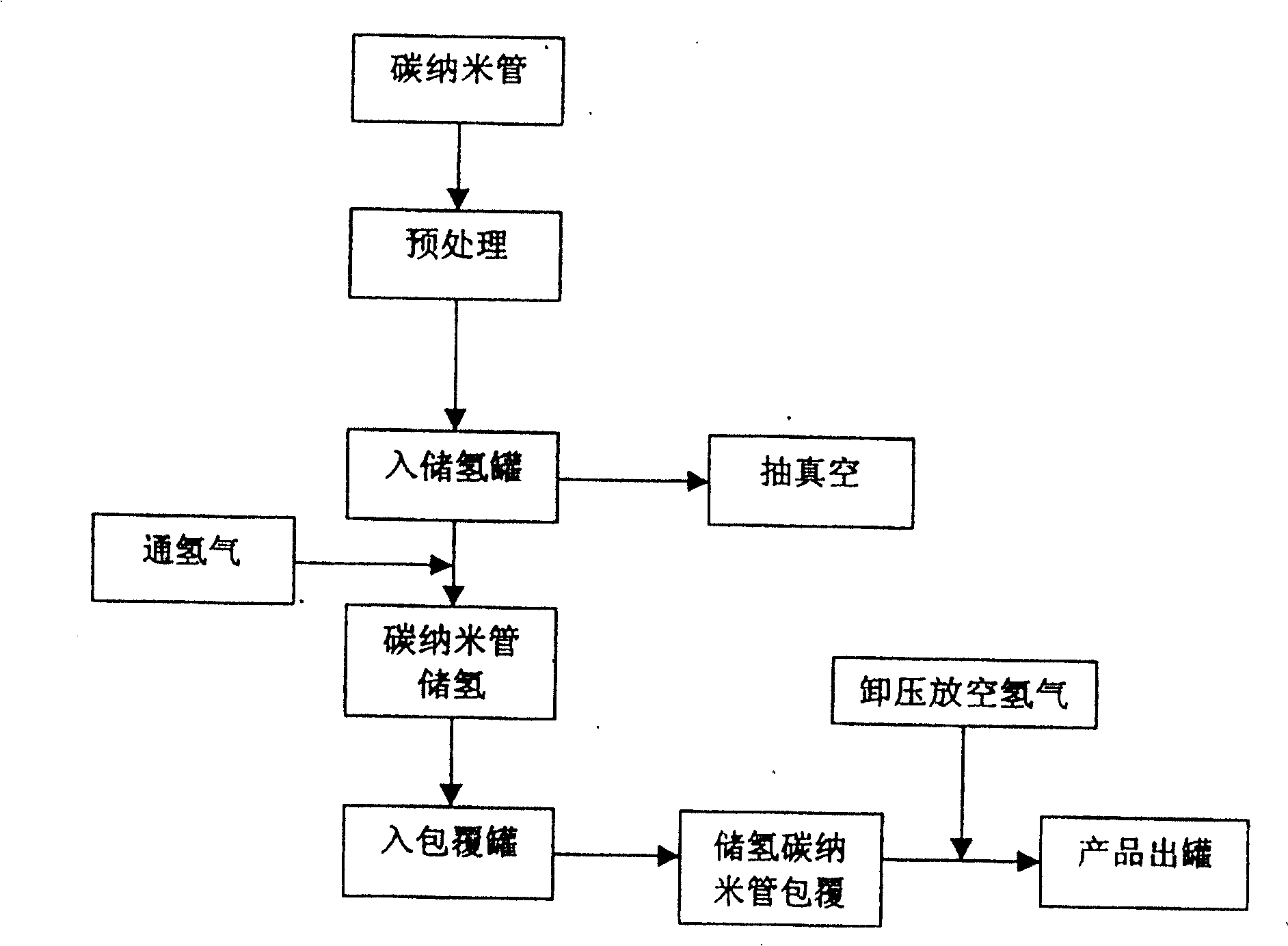

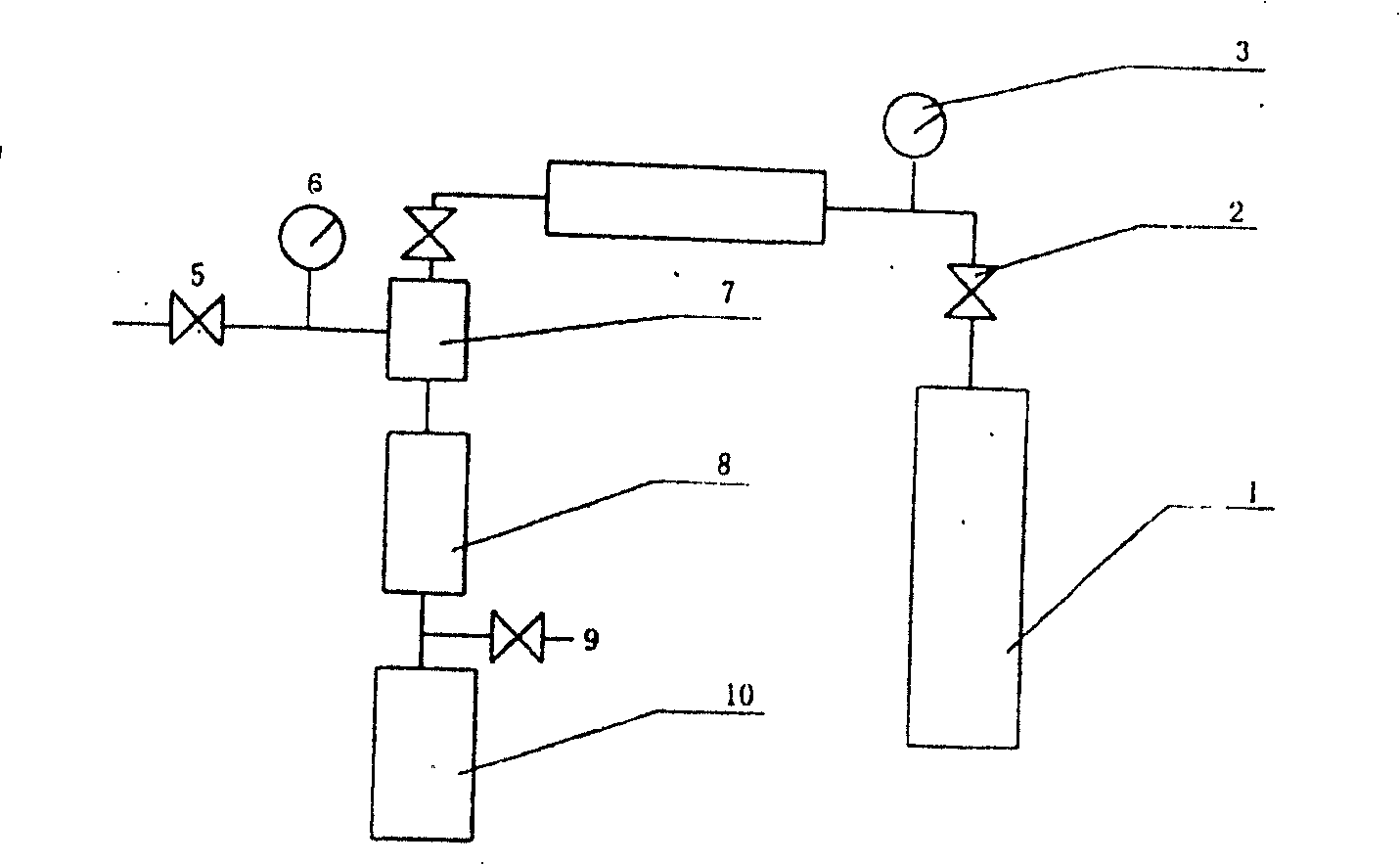

[0017] to combine figure 1 , figure 2 , a specific embodiment of the present invention is:

[0018] The first step: pretreatment of carbon nanotubes, including purification, washing, drying, shearing and dispersion of carbon nanotubes;

[0019] The second step: observe the pressure gauge 3 and pressure gauge 6, check the air tightness of the system, and prevent the system from being poorly connected;

[0020] The third step: close valve 2, relief valve 5, pressure valve 9 and three-way valve 7, and relief valve 5 and feeding valve on hydrogen storage tank 8 and coating tank, and open the vacuum on hydrogen storage tank and coating tank respectively The valve evacuates the system;

[0021] Step 4: open the feed valve on the hydrogen storage tank 8 and quickly add carbon nanotubes to the hydrogen storage tank and close the feed valve; open the feed valve on the coating tank to quickly add the coating agent and close the feed valve;

[0022] Step 5: Open the valve 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com