Modified epoxy resin for solvent-free fireproof coating and preparation method of modified epoxy resin

A technology of epoxy resin and fireproof coatings, which is applied in fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems of unseen polyhedral silsesquioxane research, achieve improved flame retardant efficiency, and make raw materials cheap and easy to use The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

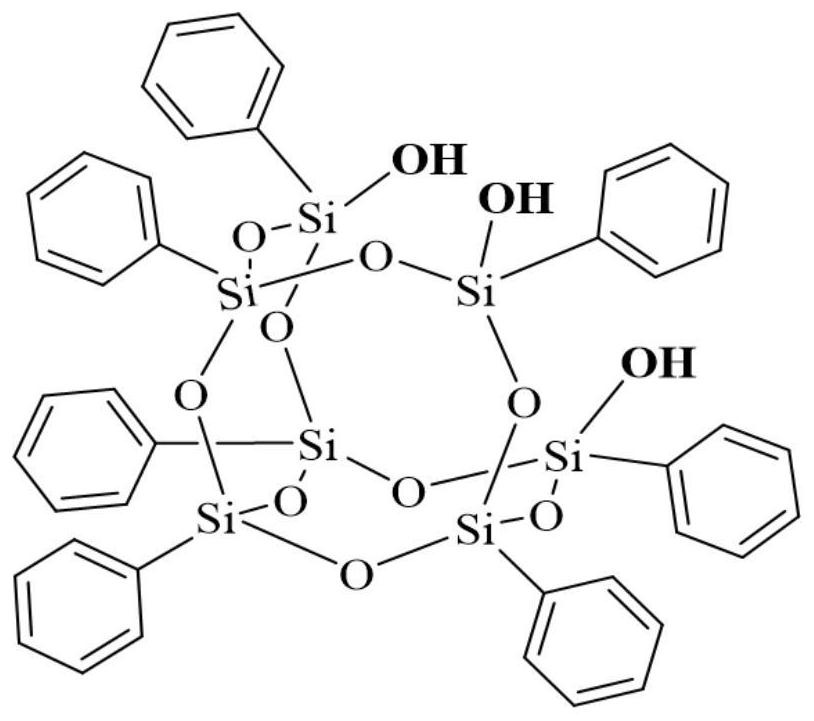

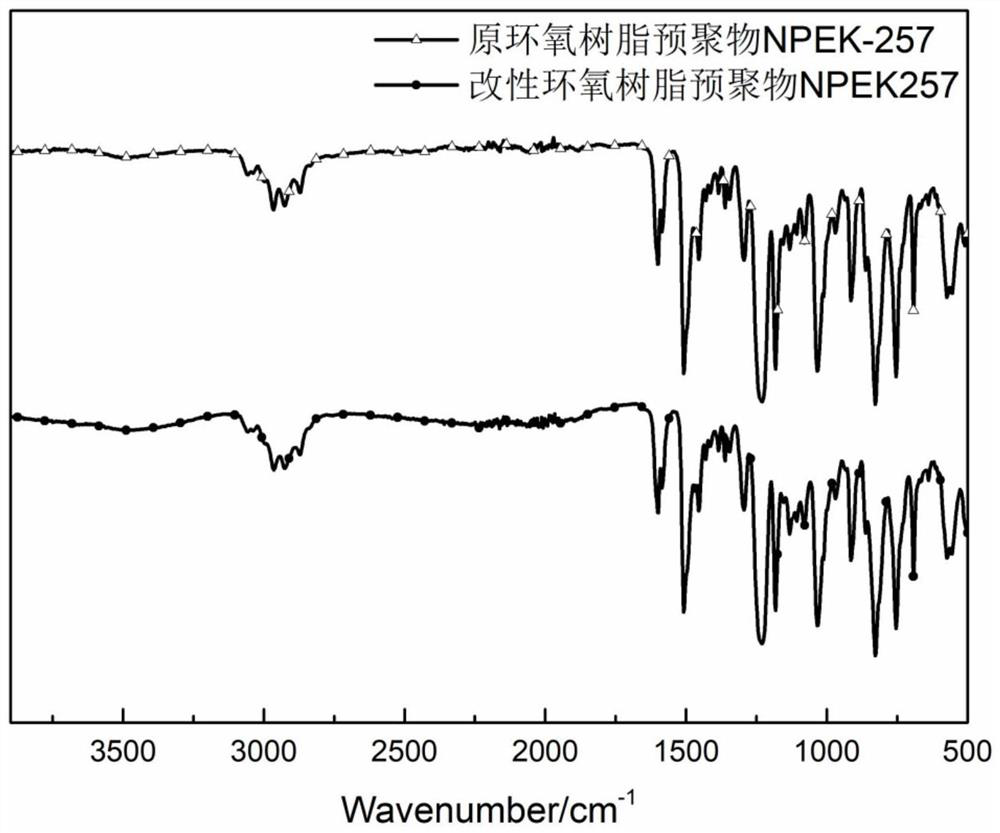

[0046] A modified epoxy resin for solvent-free fireproof coatings, the preparation method is: at room temperature, after mixing 2.5g heptaphenylsilsesquioxane trisilanol and 72.5g epoxy resin prepolymer NPEK-257, put Stir and disperse in the dispersing equipment for 120min until uniform, obtain the modified epoxy resin prepolymer; at room temperature, after mixing 2.5g heptaphenylsilsesquioxane trisilanol and 22.5g curing agent isophoronediamine, Put into the dispersing equipment and stir and disperse for 30 minutes until it is uniform to obtain a modified curing agent; at room temperature, put the modified epoxy resin prepolymer and modified curing agent obtained in the above steps into the dispersing equipment and stir for 15 minutes until uniform, Curing at room temperature for 8 hours and continuing curing at 80° C. for 30 minutes to obtain the modified epoxy resin for the solvent-free fireproof coating.

[0047] Test result: the limiting oxygen index is 24%. Cone calorim...

Embodiment 2

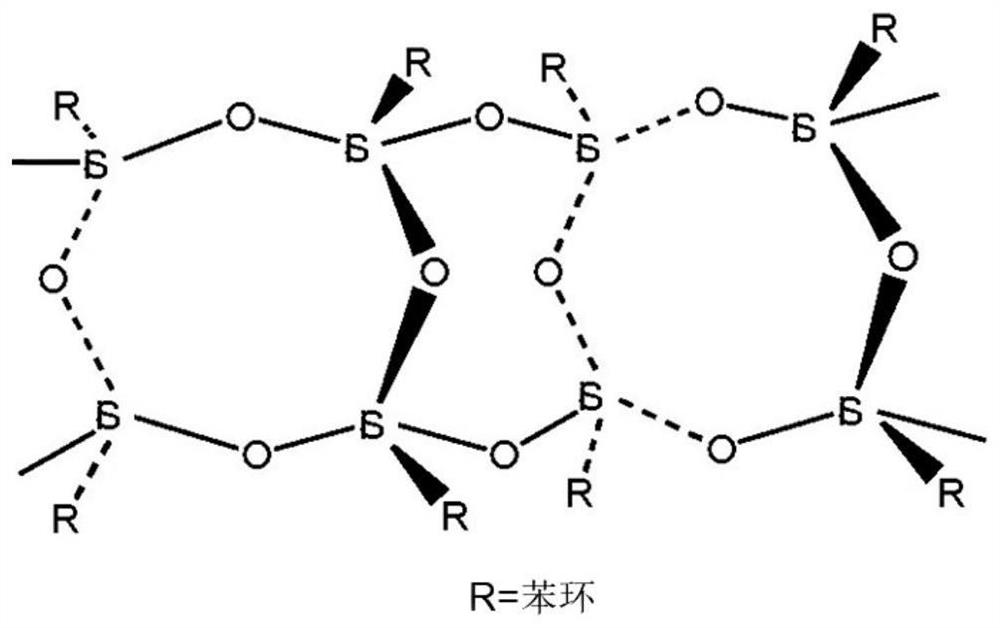

[0049] A modified epoxy resin for solvent-free fireproof coatings, the preparation method is: at room temperature, after mixing 5g of trapezoidal phenylsilsesquioxane and 25g of curing agent isophoronediamine, put it into a dispersion device and stir Disperse for 30 minutes until uniform to obtain a modified curing agent; at room temperature, put 75g of epoxy resin prepolymer NPEK-257 and the modified curing agent obtained in the above steps into a dispersion device and stir for 15 minutes until uniform, and cure at room temperature for 8 hours , continue curing at 80° C. for 30 minutes to obtain the modified epoxy resin cured product for the solvent-free fireproof coating.

[0050] Test result: the limiting oxygen index is 24.2%. Cone calorimeter combustion test results show that the peak heat release rate is 912kW / m 2 , when the test time is 525s, the total smoke release is 2622m 2 / m 2 , the mass loss rate is 96%.

Embodiment 3

[0052] A modified epoxy resin for solvent-free fireproof coatings, the preparation method is: at room temperature, 2g heptaphenylsilsesquioxane trisilanol, 2g trapezoidal phenylsilsesquioxane and 71g epoxy resin After the polymer NPEK-257 is mixed, put it into the dispersing equipment and stir and disperse for 120min until it is uniform to obtain the modified epoxy resin prepolymer; Phoronediamine was put into a dispersing device, stirred and dispersed for 30 minutes until uniform, cured at room temperature for 8 hours, and continued to be cured at 80° C. for 60 minutes to obtain the modified epoxy resin cured product for the solvent-free fireproof coating.

[0053] Test result: the limiting oxygen index is 23.9%. Cone calorimeter combustion test results show that the peak heat release rate is 878kW / m 2 , when the test time is 525s, the total smoke release is 2631m 2 / m 2 , The mass loss rate is 96%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com