Precisive module regulating method of air conditioner

A precision air-conditioning and control method technology, applied in heating and ventilation control systems, heating methods, space heating and ventilation, etc., can solve problems such as difficult temperature and humidity control, energy waste, etc., to reduce energy consumption and improve control The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

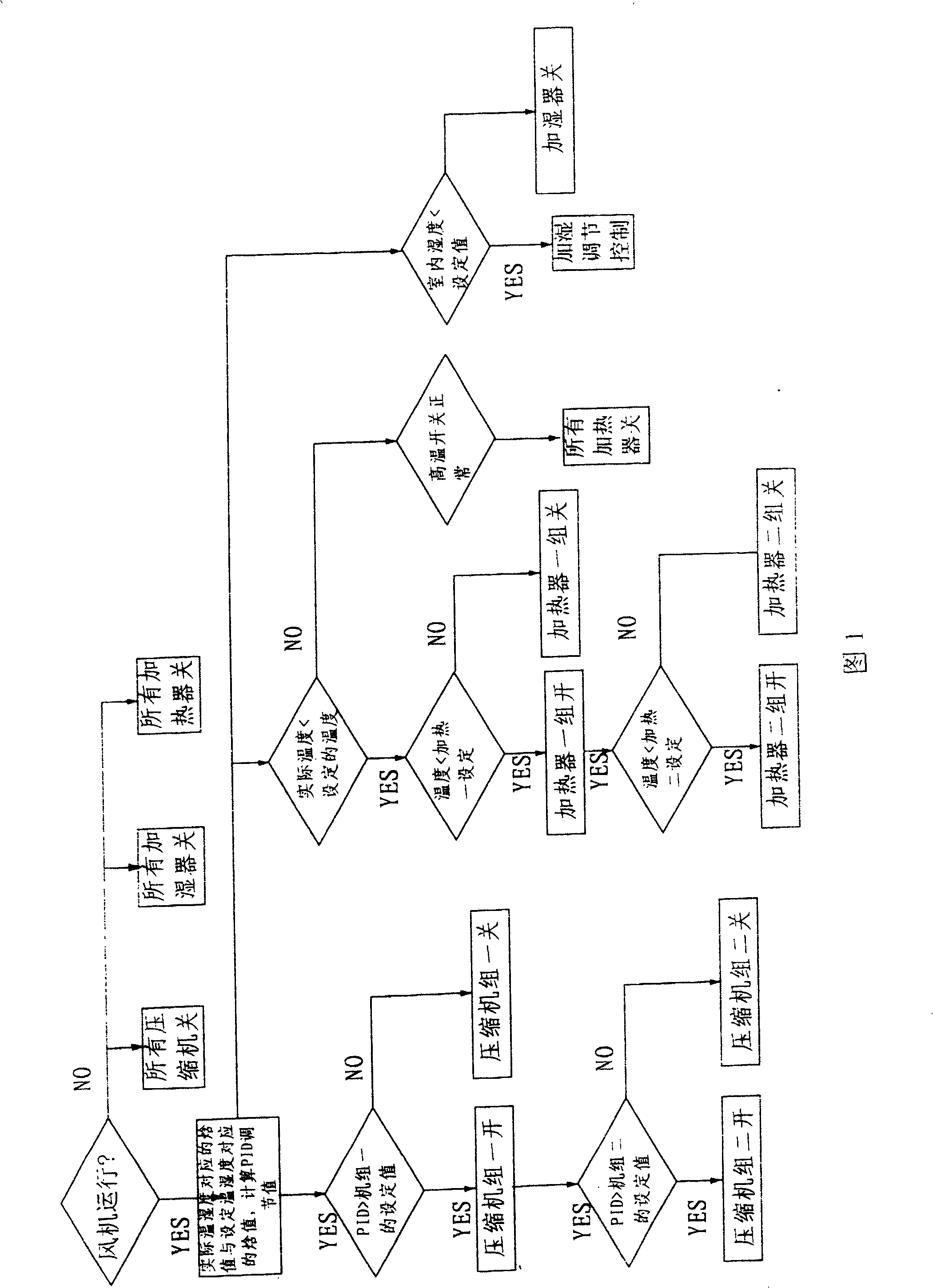

Method used

Image

Examples

Embodiment Construction

[0016] The enthalpy control operation formula of the inventive method is as follows:

[0017]

[0018] In the above formula, e(t) is the input enthalpy signal, Kp is the proportional operation, Ki∫ is the integral operation, Kd d / dt differential operation, K(1+1 / Ti S+TdS) is the PID transfer function.

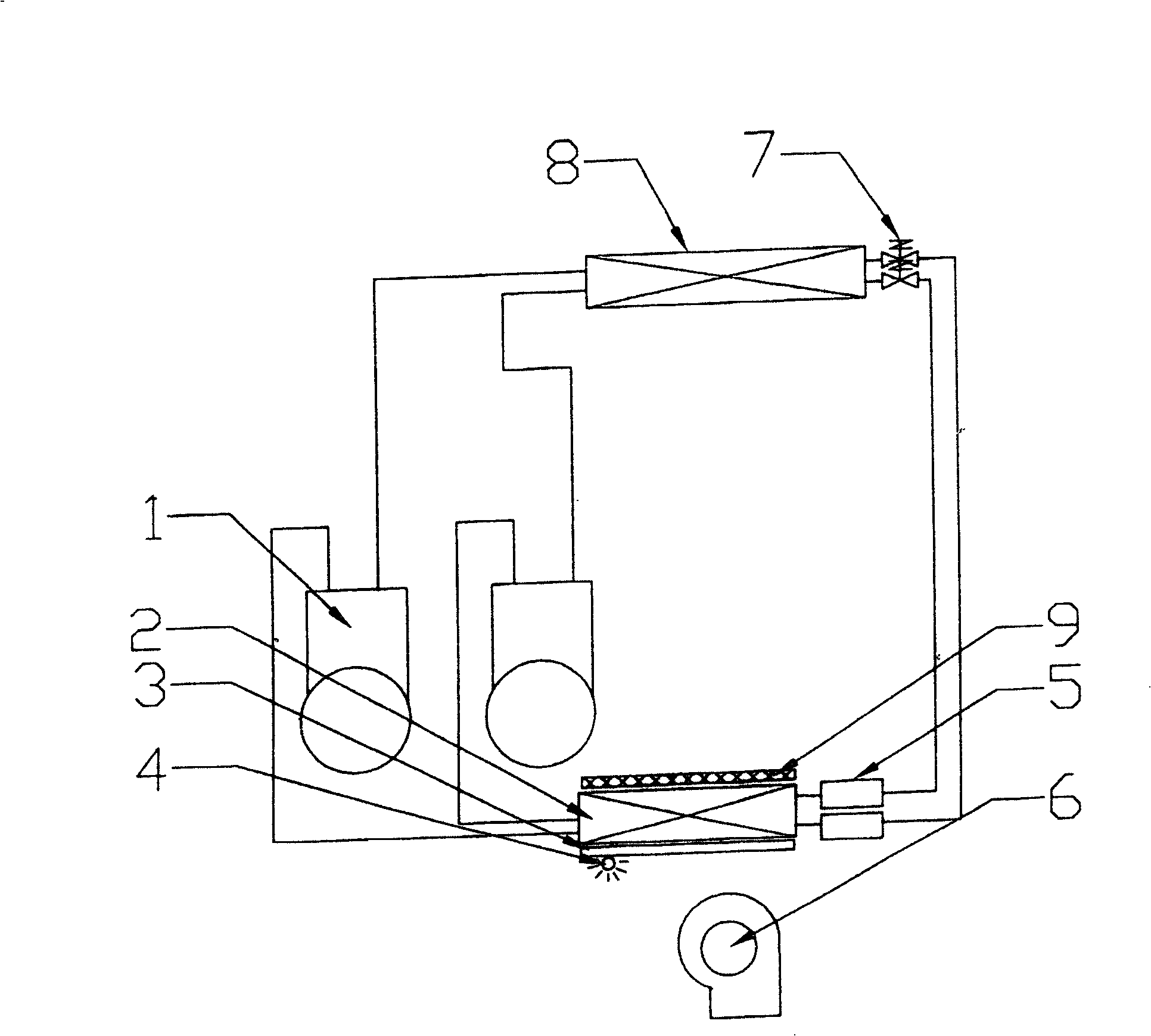

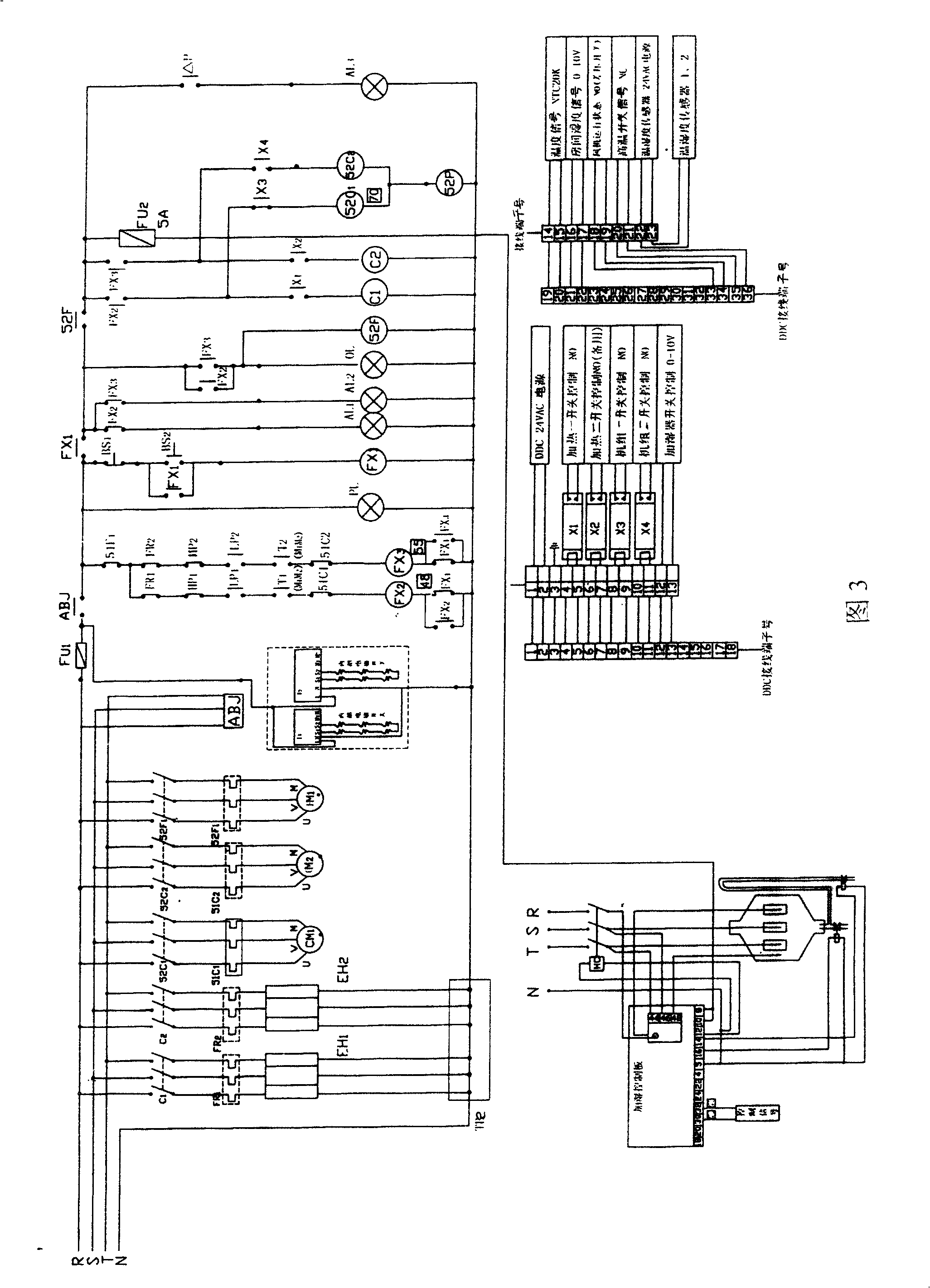

[0019] The structure of the modular precision air conditioning system is as follows: figure 2 As shown, compressor 1, evaporator 2, heating PTC 3, humidifier 4, drying filter 5, fan 6, expansion valve 7, condenser 8, filter 9; users can choose different cooling capacity and control according to actual needs High-precision modular precision air-conditioning units can be matched at will. The modular precision air conditioning system adopts a programmed digital direct controller and an enthalpy value control algorithm. Due to the fast operation speed of the microcomputer, a loop control can be completed in a short time interval, and high-precision control can be realized. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com