Continuous continuation method for closed-loop control parameters of accelerator motor control system

A motor control and closed-loop control technology, which is applied in the direction of electric controllers and controllers with specific characteristics, can solve the design complexity and cost increase of the closed-loop control system, the unfavorable shape and curvature accuracy and efficiency, and the inability to take into account the integrity and local characteristics to achieve the effect of solving low control precision, solving accuracy and low efficiency, and eliminating correlation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe in detail the technical content, structural features, achieved objectives and effects of the technical solution, the following detailed description is given in conjunction with specific embodiments and accompanying drawings.

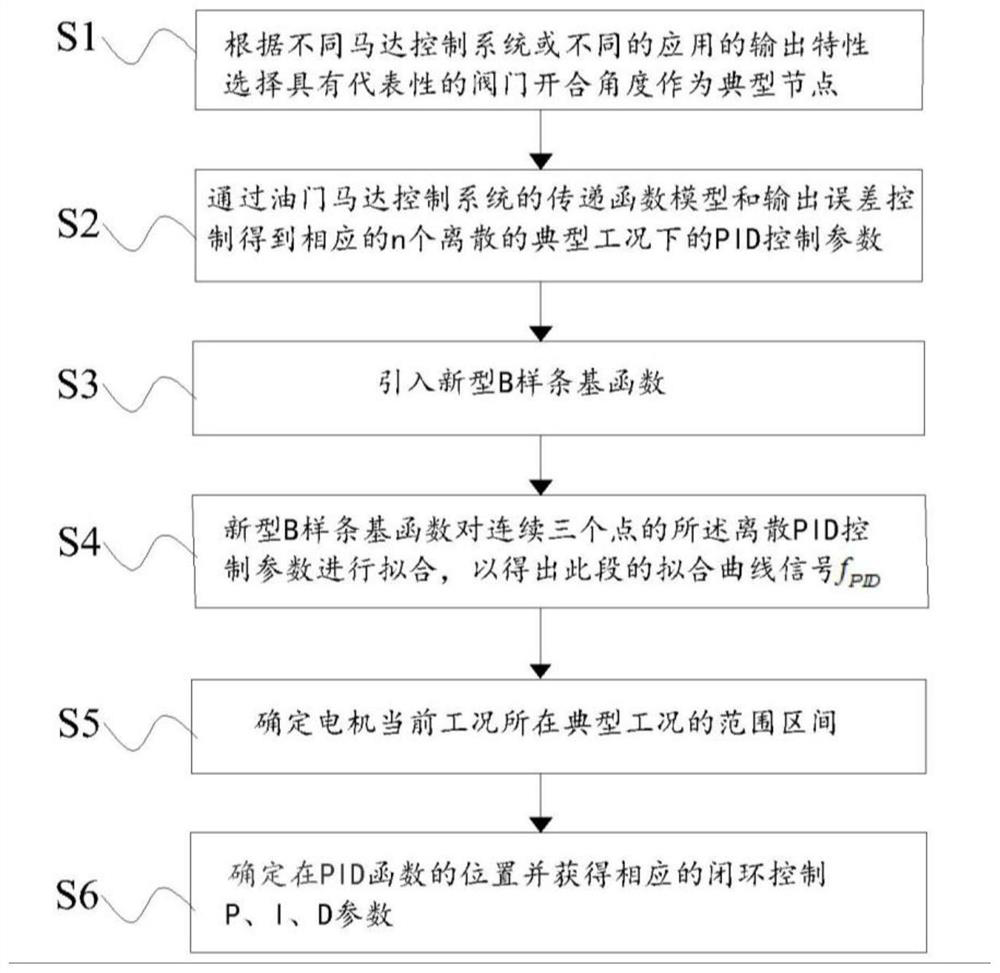

[0018] see figure 1 , In this embodiment, a method for continuous continuation of closed-loop control parameters of a throttle motor control system includes the following steps:

[0019] S1: Select a representative valve opening and closing angle as a typical node according to the output characteristics of different motor control systems or different applications;

[0020] S2: The corresponding n discrete PID control parameters M are obtained through the transfer function model of the throttle motor control system and the output error control i (P i ,I i ,D i ), i=0,...,n-1, where P i ,I i ,D i is the PID control parameter of the i-th node;

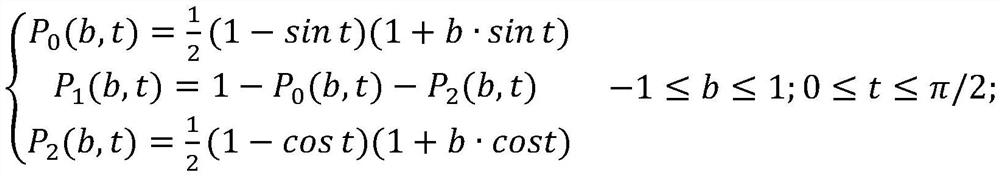

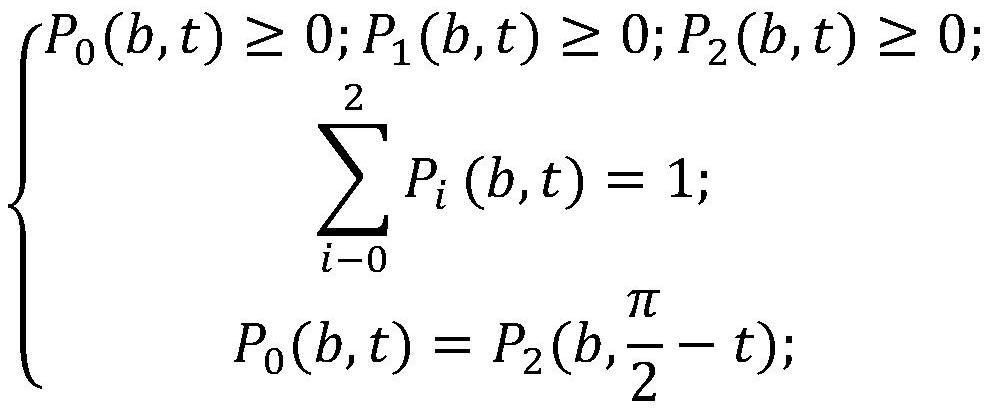

[0021] S3: The new B-spline basis function is introduced as:

[0022]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com