Automation device for LED test table

A technology of light-emitting diodes and automation devices, which is applied to measurement devices, photometry, optical radiation measurement, etc., can solve the problems of easy tilt, complex structure, damage to light-emitting diodes, etc., and achieves the effect of simple structure and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

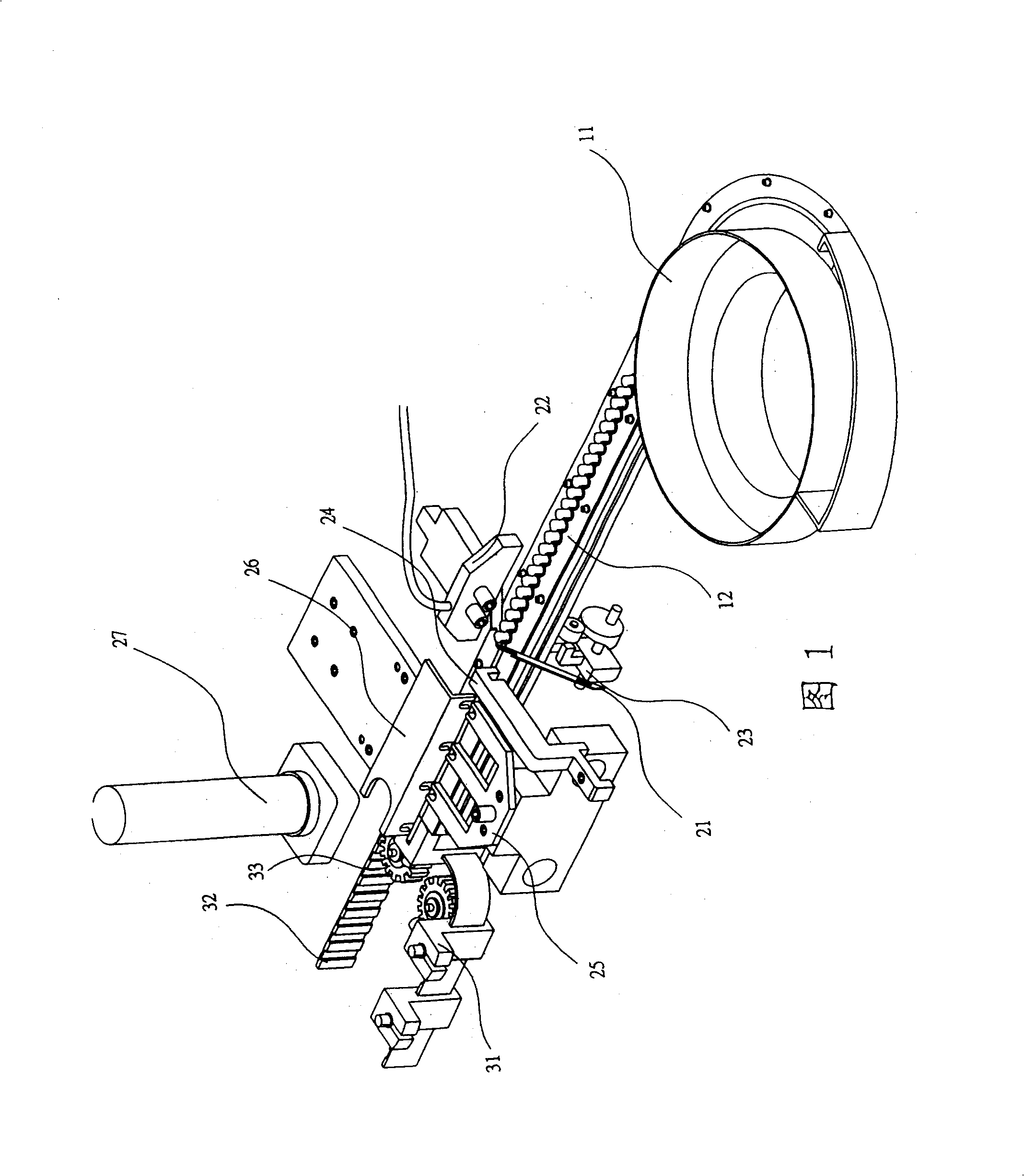

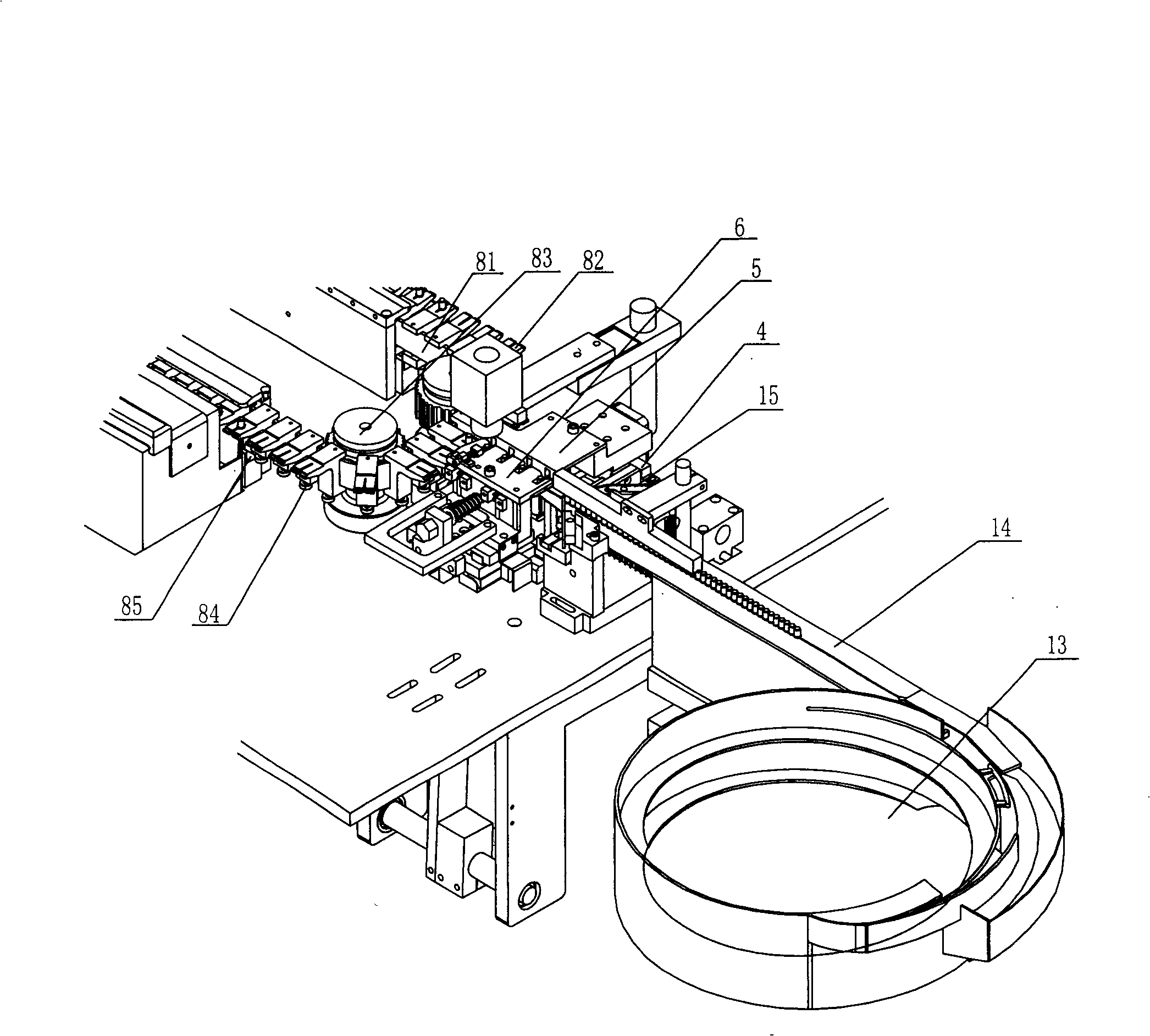

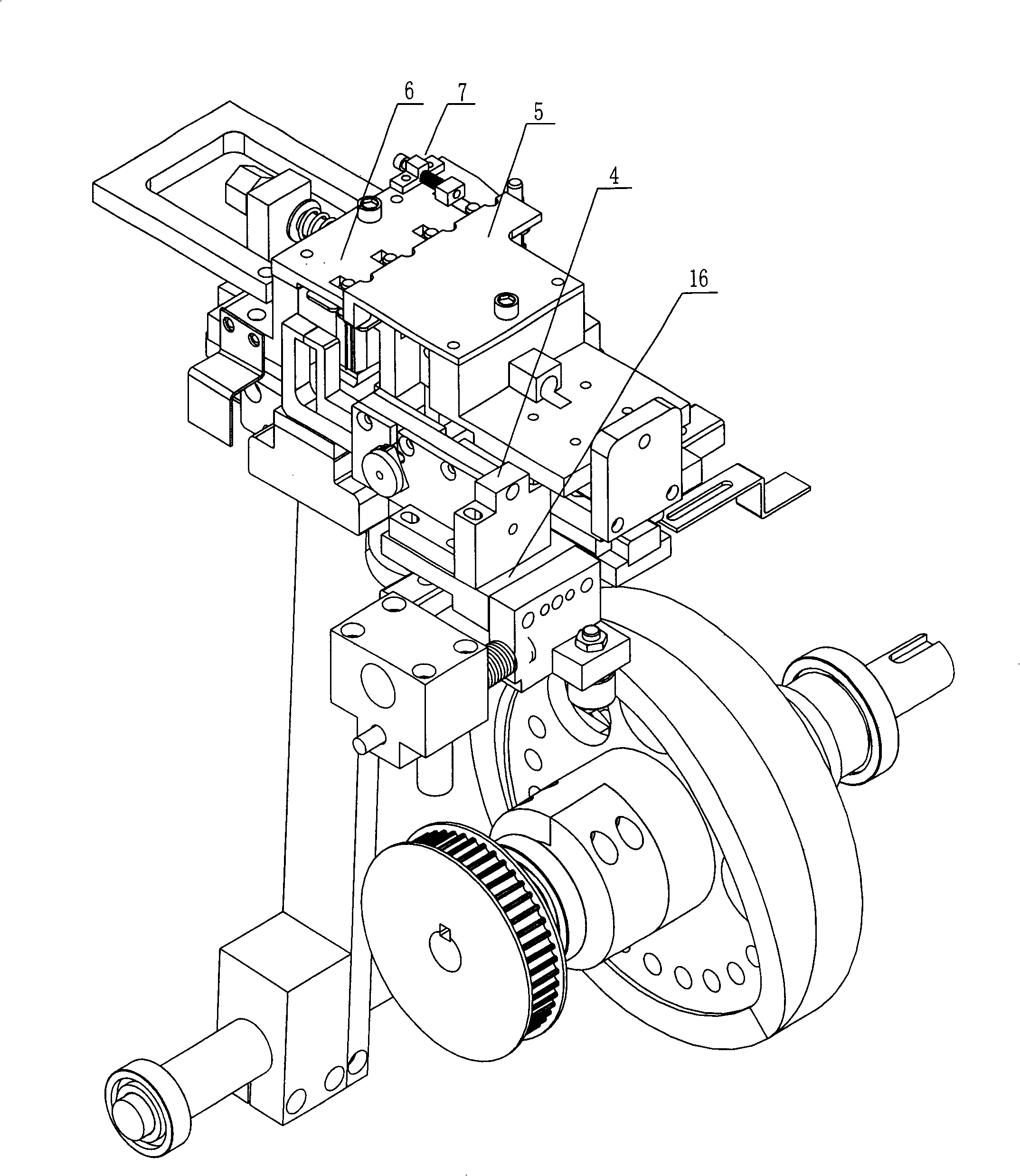

[0033] An automatic device for a light-emitting diode testing machine includes a group of feeding structures, a positioning testing structure and a group of discharging structures.

[0034] The feed structure is made up of the following components: See figure 2 , image 3, its feeding end is a circular vibrating plate 13, and a flat vibrating plate 14 is connected with it, and the flat vibrating plate 14 extends to the front end of the test section, and is just connected with the front end of the test section; the flat vibrating plate 14 is forward When extending to an appropriate place in front of the test section, a retaining claw 15 is arranged above; the feeding jaw group 4 is arranged on the large slide plate at the end side of the flat vibrating plate 14, and the feeding jaw set 4 is arranged on the small slide plate. There ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com