Micro modular pasting header for high speed fully automatic chip machine

A fully automatic, placement head technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve problems such as restricting the popularization of technology, achieve high control accuracy, facilitate system integration and system optimization, weight and Volume reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

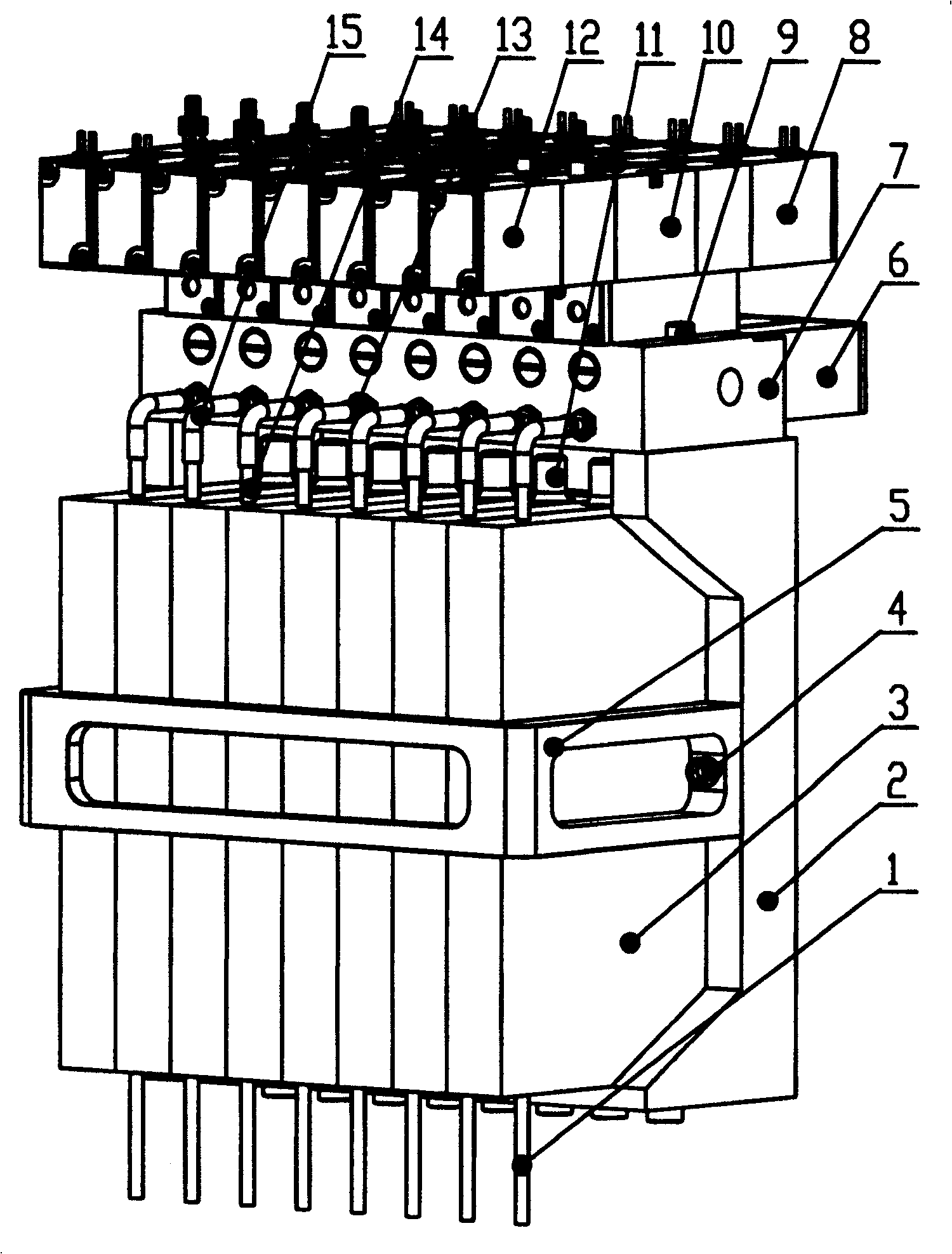

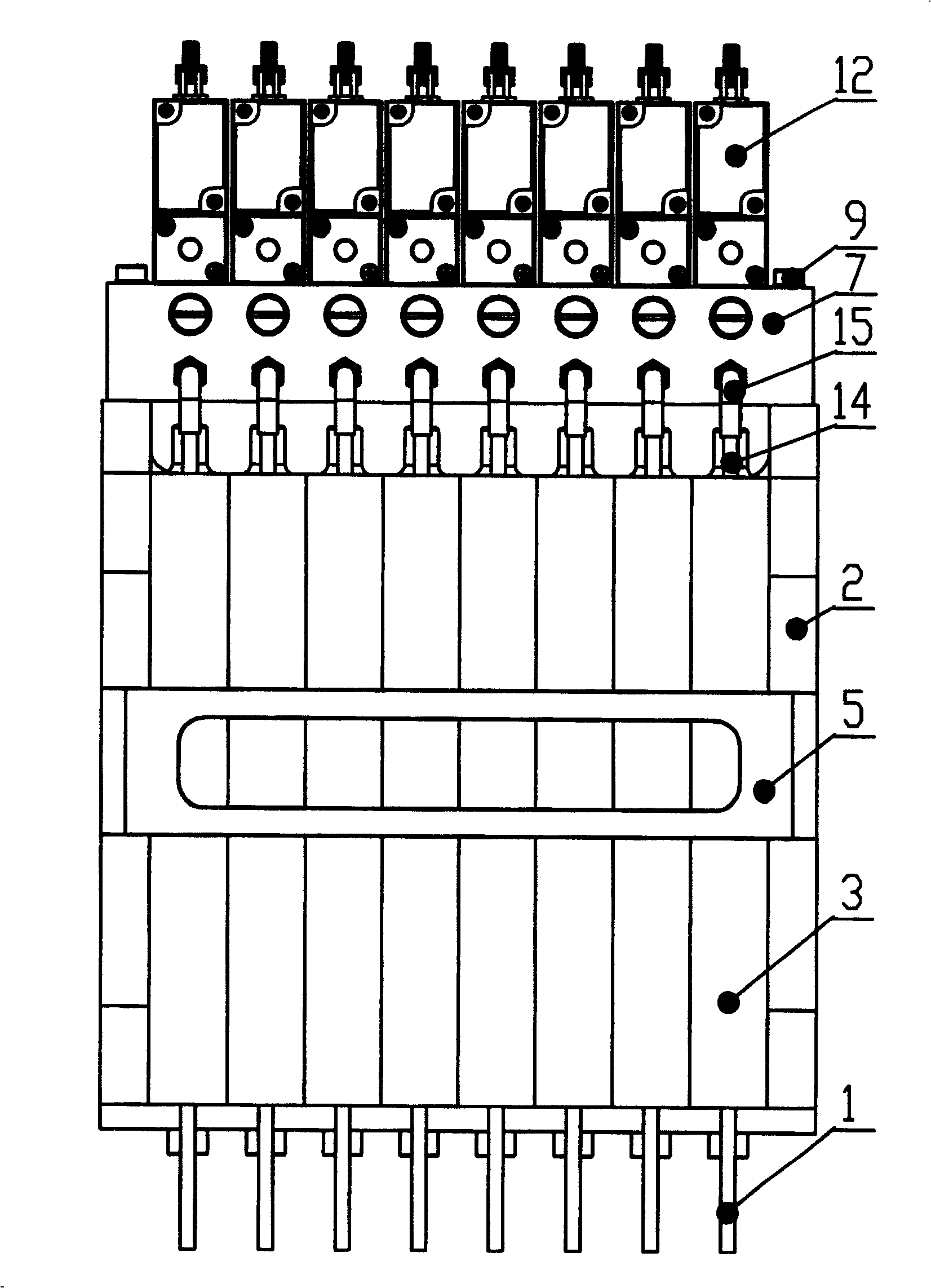

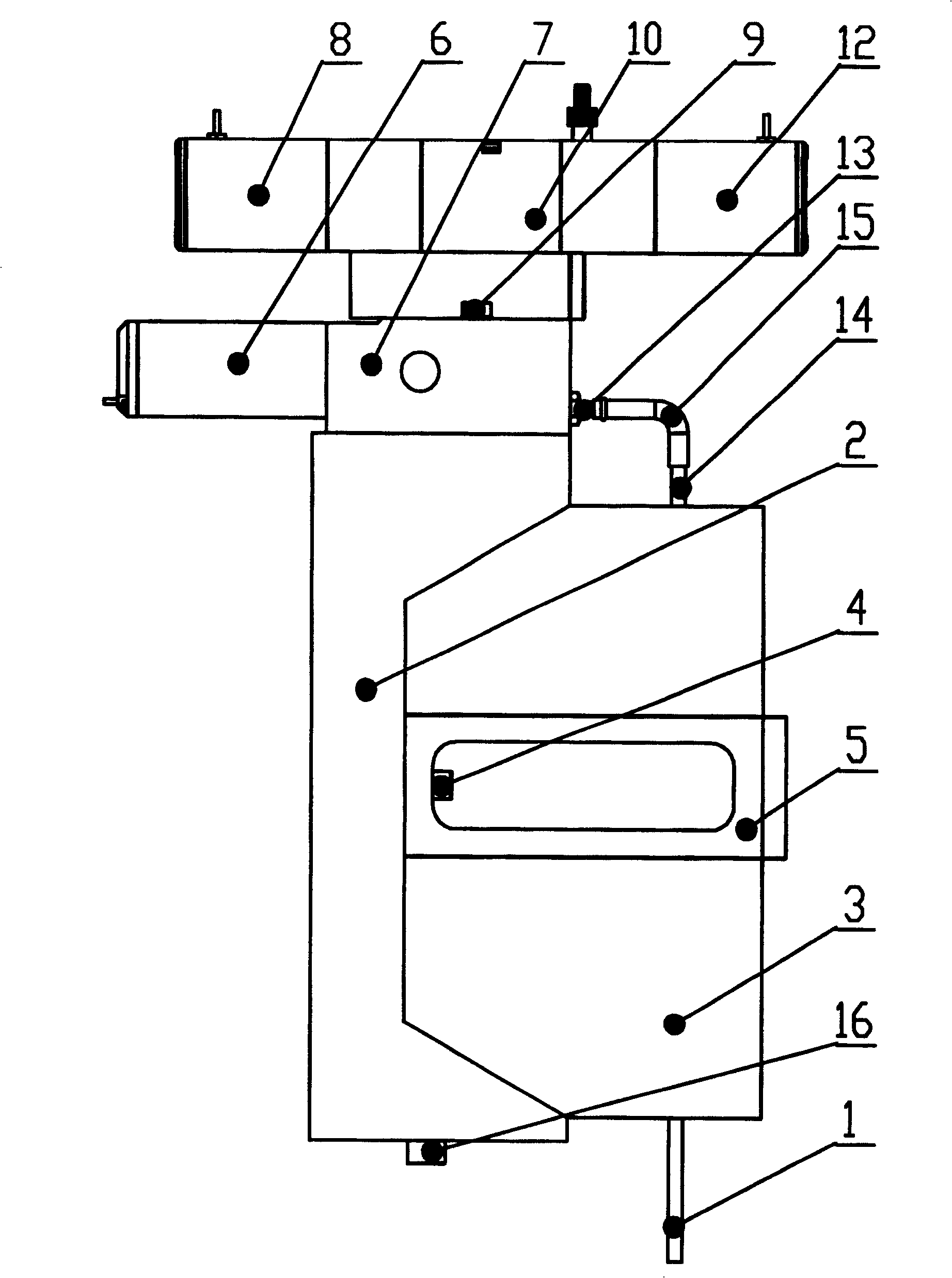

[0027] The miniature modular placement head of the high-speed automatic placement machine includes a fixed frame, a placement module and a vacuum module, and is characterized by:

[0028] Such as figure 1 As shown, the fixed frame is a dustpan-shaped frame composed of the main frame 2 and the sub-frame 5, and the bottom of the dustpan-shaped frame has a horizontal positioning surface and a vertical positioning surface; the shape of the mounting module is a Cuboid, the bottom and side surfaces of the cuboid-shaped placement module are positioning surfaces, which match with the positioning surface of the fixed frame; the vacuum module is located directly above the fixed frame.

[0029] Such as figure 1 , image 3 , Figure 5 As shown, the fixed frame includes a main frame 2 and a sub-frame 5. There are baffles on three sides of the main frame 2, and the upper end is open for connecting cables. There are two rows of countersunk screw holes at the back of the main frame 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com