Convection high efficiency internal combustion engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

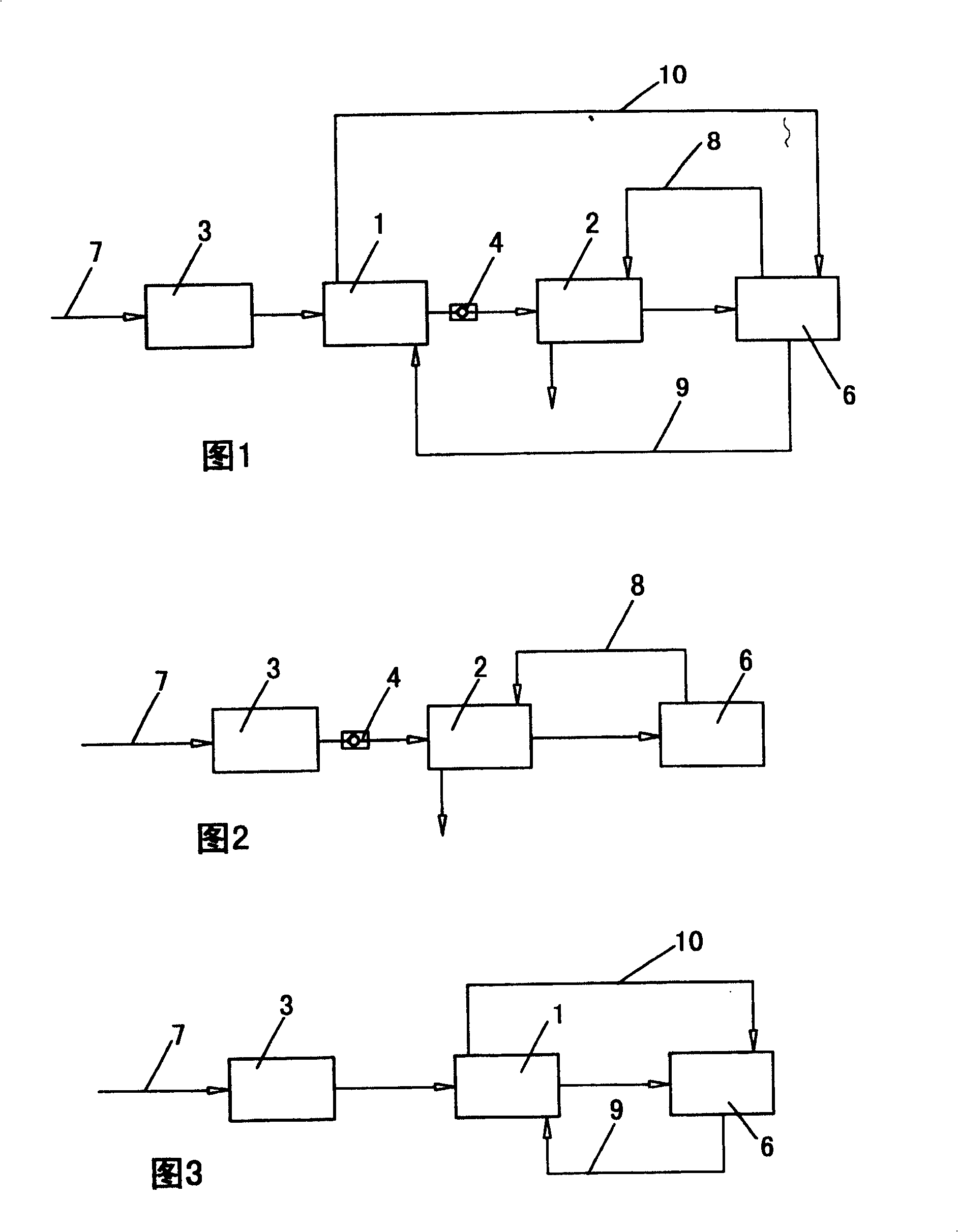

[0035] Please refer to Fig. 1, supercharger 3, water warmer 1, check valve 4, exhaust warmer 2 are installed on the pipeline of described engine intake system, and normal temperature and pressure air 7 enters after this supercharger Water warmer 1, the engine drain pipe is connected to the warmer 1, the outlet of the warmer 1 is connected to the air inlet of the exhaust warmer 2, the exhaust pipe of the engine is connected to the outlet of the warmer 2, and the outlet of the warmer 2 is connected to the engine The air inlet of the engine exhaust gas is discharged from the intake end of the exhaust warmer 2. The air 7 at normal temperature and pressure enters the engine 6 after being supercharged by the supercharger, heated by the water heater, and reheated by the exhaust heater.

[0036] Working principle of embodiment one:

[0037] 1. Supercharging

[0038] The normal temperature and pressure air entering the internal combustion engine passes through the supercharger to inc...

Embodiment 2

[0043] Please refer to Fig. 2, a supercharger 3, a check valve 4, and an exhaust gas warmer 2 are installed on the pipeline of the engine intake system, and the normal temperature and pressure air 7 enters the exhaust gas warmer 2 after passing through the supercharger , the exhaust pipe 8 of the engine communicates with the outlet of the warmer 2, the outlet of the warmer 2 communicates with the air inlet of the engine, and the engine exhaust gas is discharged from the intake end of the exhaust warmer 2.

[0044] The air 7 at normal temperature and pressure enters the engine 6 after being supercharged by the supercharger and heated by the exhaust gas warmer 2 .

Embodiment 3

[0046] Please refer to Fig. 3, a supercharger 3 is installed on the pipeline of the engine air intake system, the normal temperature and pressure air 7 enters the water warmer 1 after passing through the supercharger, and the engine drain pipe 9 communicates with the outlet of the warmer 1 The outlet of the warmer 1 communicates with the air inlet of the engine, and the cooling water cooled by the warmer 1 returns to the engine along the return pipe 10 .

[0047] The air 7 at normal temperature and pressure enters the engine 6 after being supercharged by the supercharger 3 and heated by the water warmer 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com