Constant-temperature and constant humidity store house variable capacity automatic controlling system

An automatic control system, constant temperature and humidity technology, applied in the field of constant temperature storage control, can solve problems such as poor adaptability, achieve the effects of convenient operation, excellent control quality, and significant energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and examples.

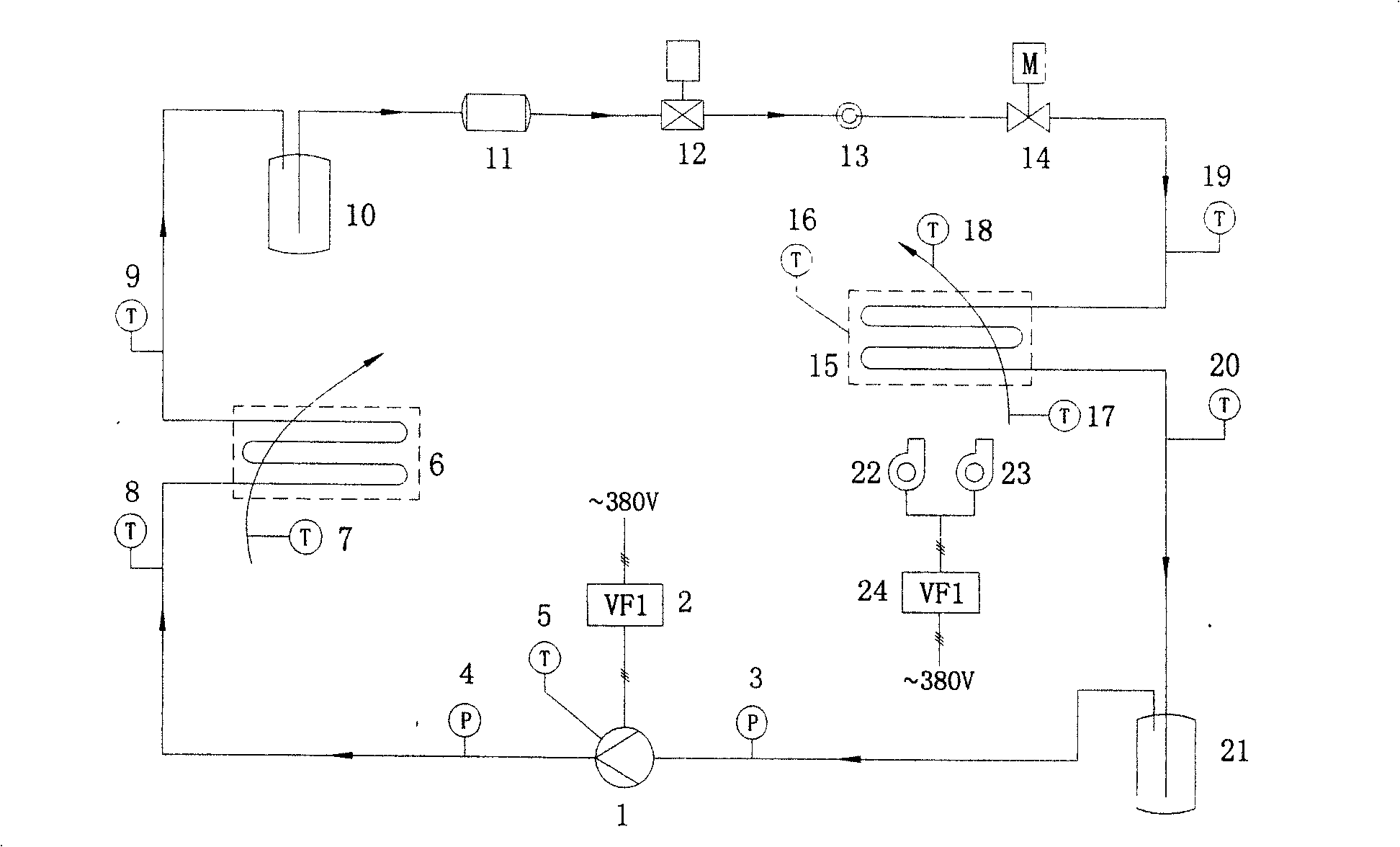

[0020] In the present invention, the combined variable capacity control of the compressor and the air cooler is adopted. In the choice of control strategy, PLC is a kind of industrial computer, which realizes various control purposes through user editing programs. It has the advantages of high reliability, simple programming and easy maintenance, and has been widely used in industrial control. This system uses Siemens S7-300 medium-sized PLC as the controller to realize intelligent control of the whole unit, achieving the dual purpose of energy saving and optimal control. System control mainly includes: parameter control, safety control, automatic operation control and defrosting control.

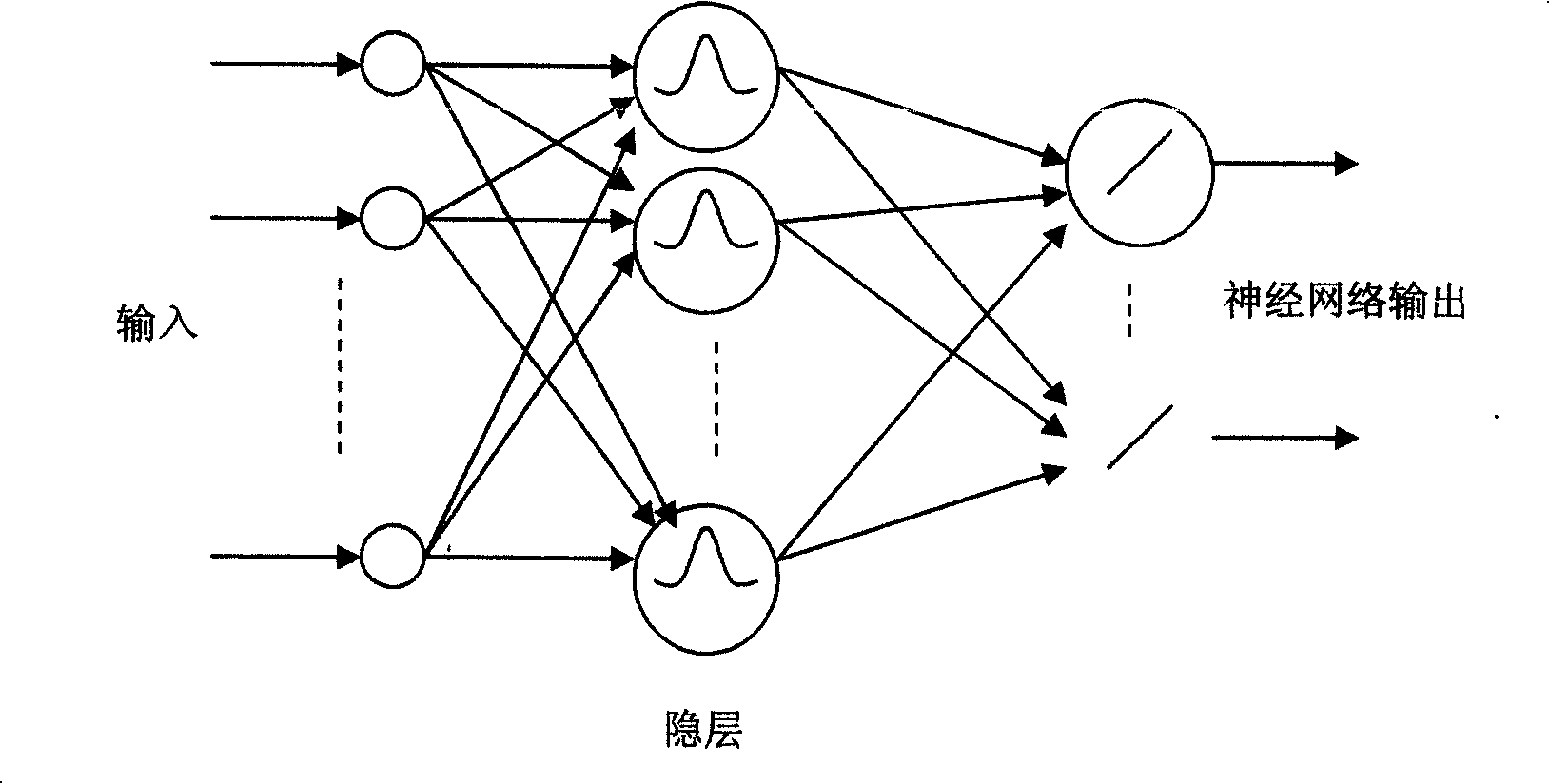

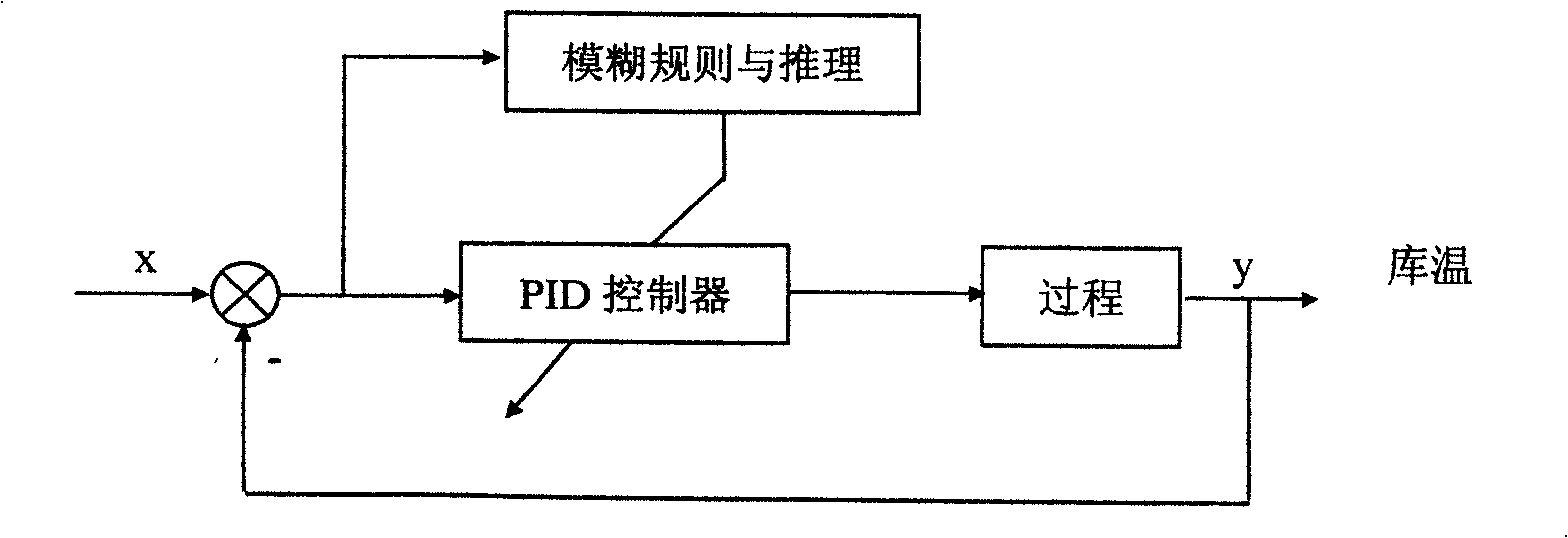

[0021] In the present invention, the fuzzy control theory based on the language rule model is combined with the neural network theory with self-learning and arbitrary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com