Leaked water collector and its mounting construction method

A construction method and collector technology, applied in water supply installations, indoor sanitary pipeline installations, buildings, etc., can solve problems such as easy occurrence of moisture return, water seepage retention in toilets, and easy breeding of bacteria, so as to avoid environmental pollution, prevent moisture return, prevent seepage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

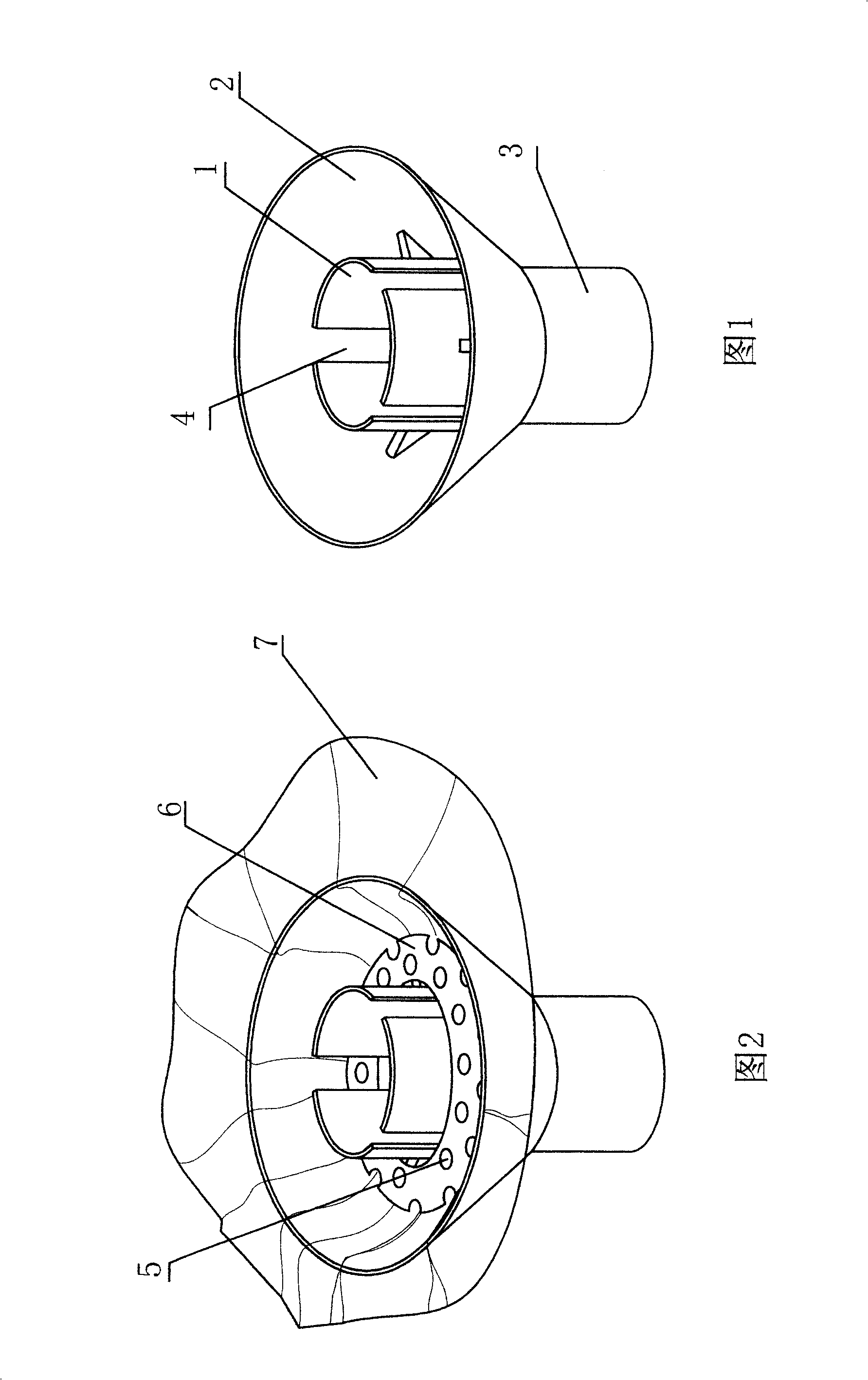

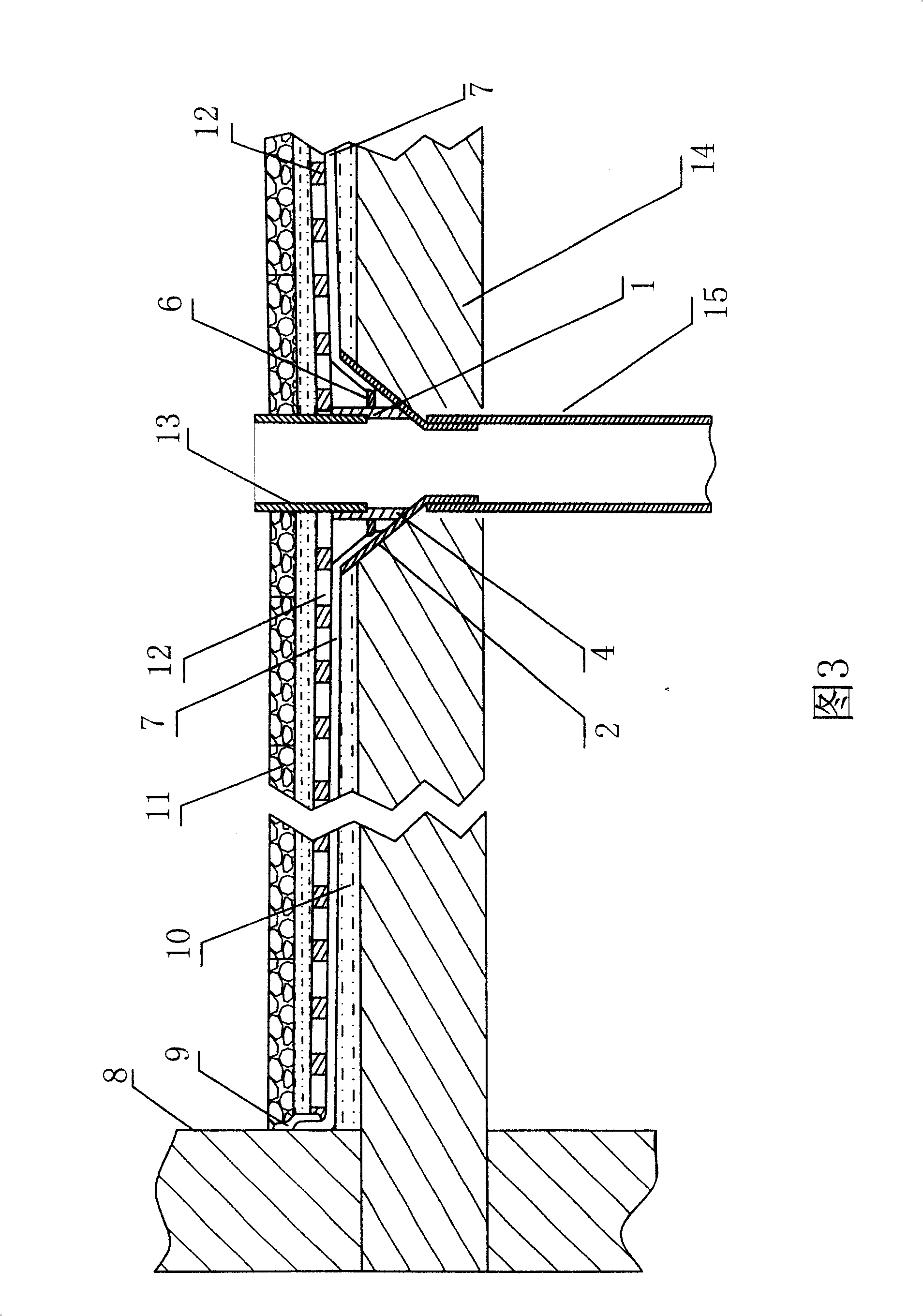

[0016] Embodiment: As shown in Figure 1 and Figure 2, it is composed of a drainage funnel 2, a drainage pipe seat 1, a lower drainage pipe 3, etc., wherein the outlet of the drainage funnel 2 is the lower drainage pipe 3, and the lower drainage pipe 3 can be socketed On the indoor PVC drain pipe 15, the outer diameter of its nozzle is less than the inner diameter of the indoor drain pipe 15. A drain pipe seat 1 is provided on the bucket wall in the drain funnel 2, and a water outlet 4 is provided on the pipe wall of the drain pipe seat. An upper drainpipe 13 can be sleeved in the drainpipe seat 1, and the inner diameter of the drainpipe seat opening is greater than the outer diameter of the upper drainpipe 13. Whole drainage funnel 2, lower drainage pipe 3, drainage pipe seat 1 etc. all can adopt plastic injection molding such as PVC to form integrally.

[0017] A fixed ring cover 6 can be sleeved on the drain pipe seat 1, and a plurality of seepage holes 5 are provided on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com