Agent of preventing flavor component from degradation

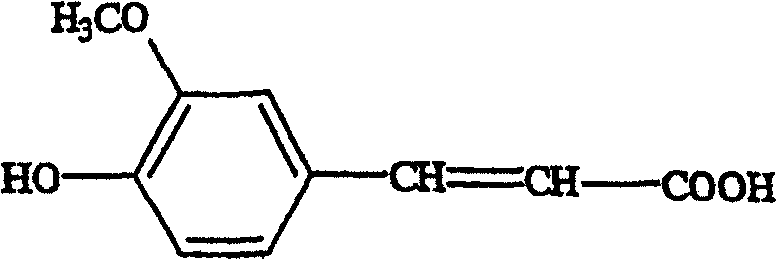

A technology of aroma components and deteriorating agents, which is applied in the direction of essential oils/fragrances, preservation of fatty substances by additives, tea extraction, etc., and can solve the problems of unstable emulsification, insufficient effect and practicability, separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

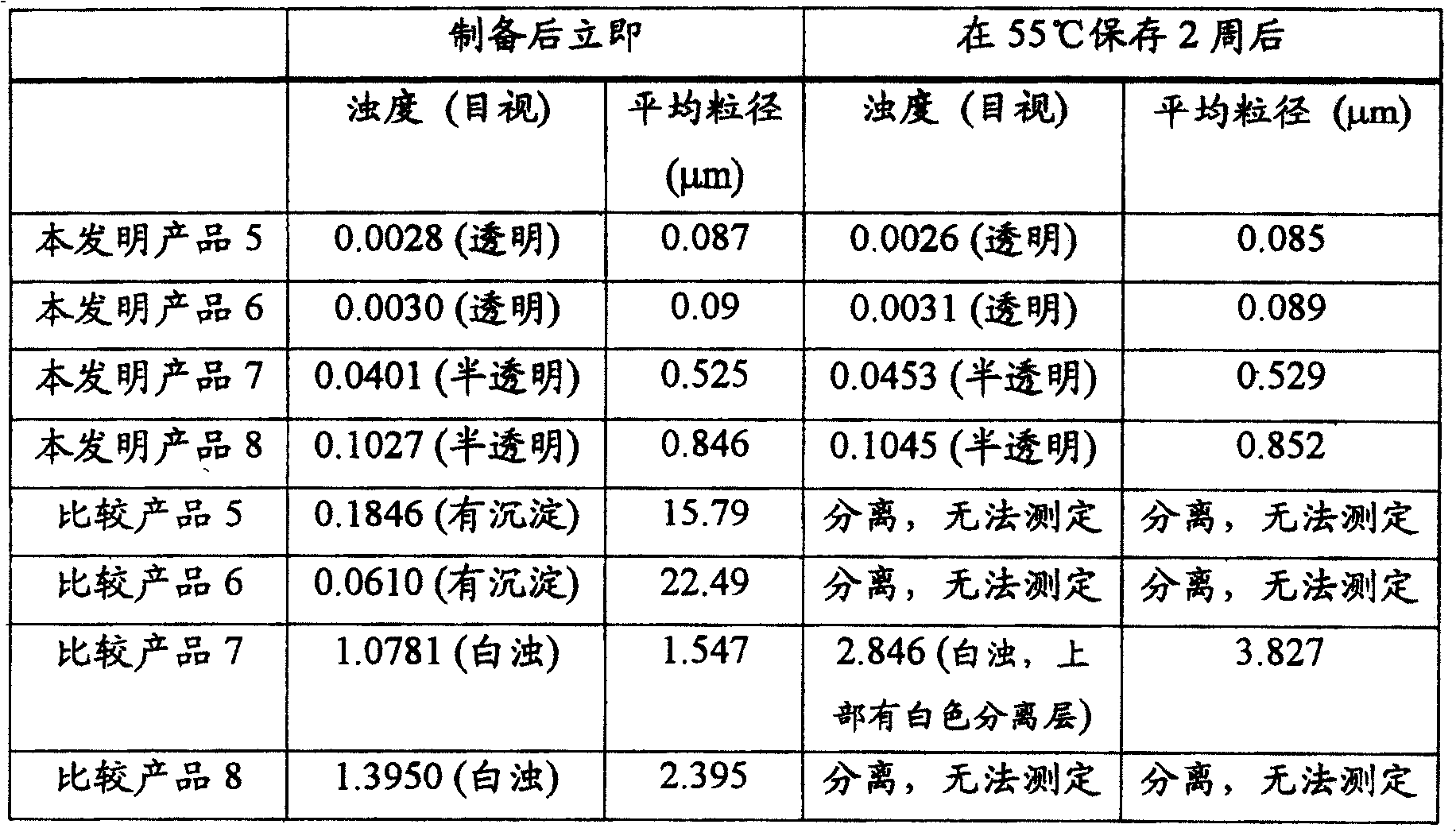

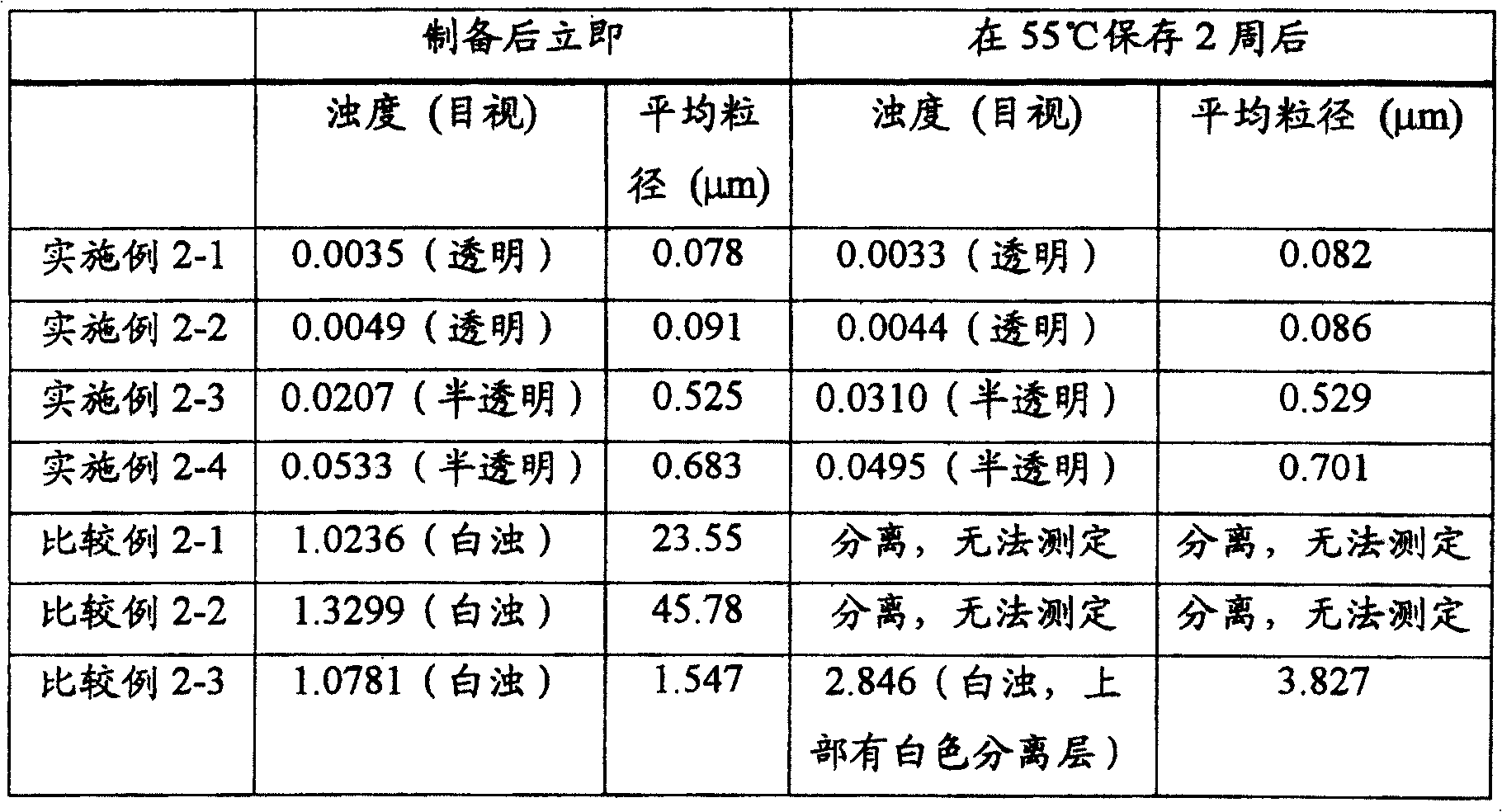

Examples

Embodiment 1-1

[0093] Add 2 g of neopentyltriol-myristate (produced by Sun Chemical Co., Ltd., HLB value 14, polyglycerol composition) as polyglycerol fatty acid ester to 95 g of glycerin (manufactured by NOF Co., Ltd.) as a polyol. Contain 45% neopentyltriol) and 2g ferulic acid (the content of ferulic acid is more than 98%, produced by Tsukino Food Industry Co., Ltd.), heated to 65°C for dissolution. Take 1 g of extracted tocopherol (manufactured by Tama Biochemical Co., Ltd., d-δ-tocopherol content is 86%) as the oil phase, add it to the polyol, and use it in a homogenizer (manufactured by Tokuji Kagaku Kogyo Co., Ltd.) ) to emulsify at a speed of 7000rpm to obtain the anti-deterioration agent of product 1 of the present invention.

Embodiment 1-2

[0095] Add 2 g of neopentyltriol-myristate (produced by Sun Chemical Co., Ltd., HLB value 14, polyglycerol composition) as polyglycerol fatty acid ester to 95 g of glycerin (manufactured by NOF Co., Ltd.) as a polyol. 45% of neopentyltriol), 1g of ferulic acid (the content of ferulic acid is more than 98%, produced by Tsukino Food Industry Co., Ltd.), and 1g of green tea extract (trade name: Sunfenon BG, catechins The content is 70%, produced by Taiyang Chemical Co., Ltd.), heated to 65°C to dissolve. Take 1 g of extracted tocopherol (manufactured by Tama Biochemical Co., Ltd., with a δ-tocopherol content of 86%) as the oil phase, add it to the polyol, and use Make it emulsify with the rotating speed of 7000rpm, obtain the anti-deterioration agent of product 2 of the present invention.

Embodiment 1-3

[0097] Add 2 g of neopentyltriol-myristate (produced by Sun Chemical Co., Ltd., HLB value is 13) as polyglycerol fatty acid ester to 95 g of glycerin (manufactured by NOF Co., Ltd.) as polyhydric alcohol, polyglycerol composition 15% of neopentyltriol), 1g of ferulic acid (the content of ferulic acid is more than 98%, produced by Tsukino Food Industry Co., Ltd.), and 1g of green tea extract (trade name: Sunfenon BG, catechins The content is 70%, produced by Taiyang Chemical Co., Ltd.), heated to 65°C to dissolve. Take 1 g of extracted tocopherol (manufactured by Tama Biochemical Co., Ltd., with a δ-tocopherol content of 86%) as the oil phase, add it to the polyol, and use Make it emulsify with the rotating speed of 7000rpm, obtain the anti-deterioration agent of product 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com