Flavor deterioration inhibitor

An inhibitor and aroma technology, which is applied in the direction of inhibiting chemical changes in compositions, dairy products, milk preparations, etc., to achieve the effect of inhibiting aroma deterioration, maintaining quality, and maintaining freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

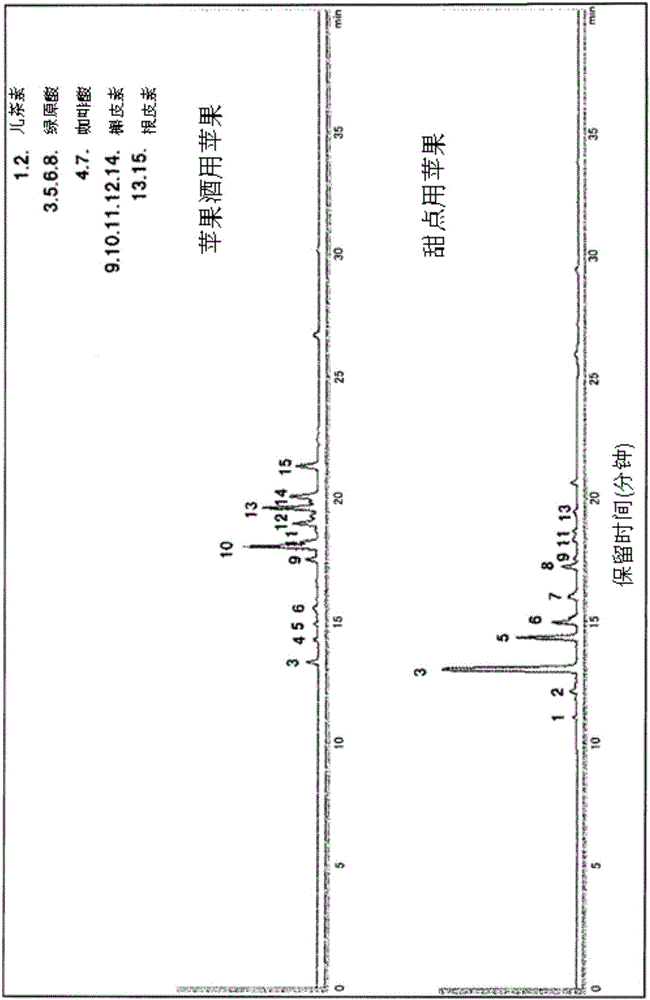

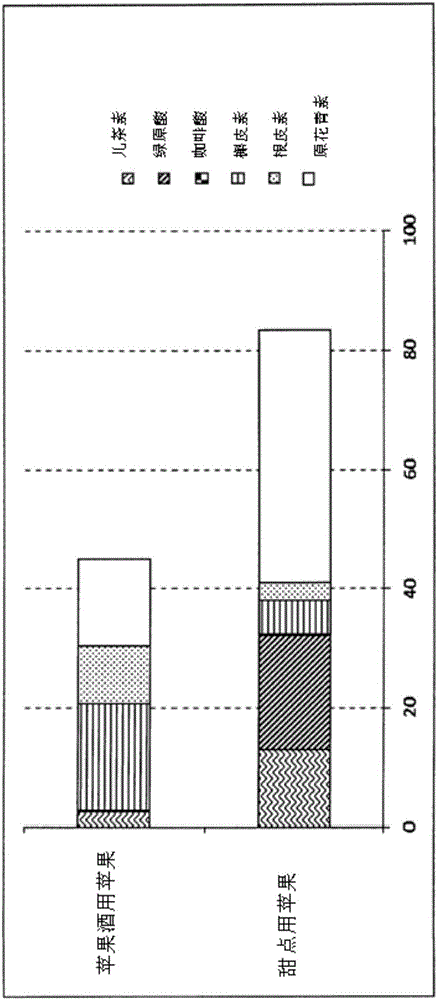

Method used

Image

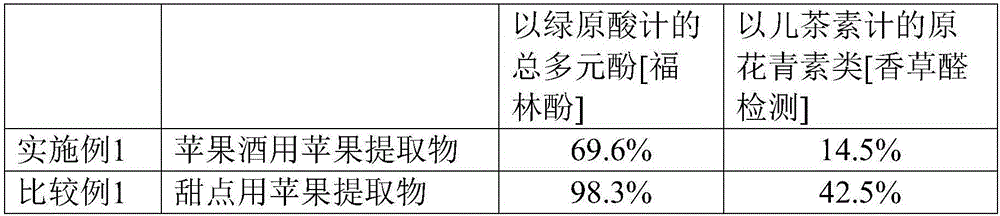

Examples

preparation example Construction

[0086] (3) Preparation of flavor deterioration inhibitor

[0087] The aroma deterioration inhibitor of the present invention contains the above-mentioned apple extract for cider (regardless of the extract treated with an adsorbent, the concentrate, and the dry solid), and may contain a diluent, a carrier, and other additives as a substance other than the resin-treated substance. components.

[0088] The diluent or carrier is not particularly limited as long as it does not hinder the effect of the present invention, and examples thereof include sugars such as sucrose, glucose, dextrin, starches, cyclodextrin, trehalose, lactose, maltose, palatinose (palatinose), xylose, starch syrup and liquid sugar, alcohols such as ethanol, propylene glycol and glycerin, reduced starch syrup, reduced maltose starch syrup, sugar alcohols such as sorbitol, lactitol, palatinitol (palatinit) , mannitol, xylitol, erythritol and maltitol, polysaccharides such as gum arabic, xanthan gum, carrageena...

Embodiment 1

[0099] 600 g of cider apples (Dabinett) were cut into small cubes, and 600 g of distilled water was added thereto, followed by pulverization using a food processor to obtain a paste. 0.24 g of pectinase was added to the paste, and extraction was performed at 50°C for 4 hours with stirring. It was cooled to 25° C., centrifuged at 4000 rpm for 30 minutes, and the supernatant was recovered. 3 g of Celite was added to the supernatant, followed by filtration. Thus, 1047 ml of a clarified crude extract of apples for cider was obtained.

[0100] 50 ml of AMBERLITE FPX-66 (manufactured by Organo Corporation) was packed into the column, and 350 ml of distilled water, 250 ml of ethanol and 250 ml of distilled water were passed through in this order to perform conditioning operation of the column. 100 ml of the crude apple extract obtained above was loaded on the column, washed with 100 ml of distilled water, and then eluted with 100 ml of 95% ethanol. Thus, an apple extract for cider...

experiment example 1

[0151] 6.41g of citric acid, 3.59g of trisodium citrate and 400g of sugar solution with sugar content (Brix value)=75 were mixed with 4590g of tap water to prepare 5000g of sugar solution with pH=3.5 and sugar content (Brix value)=6.

[0152] 350 g of sugar acid solution was filled in a transparent PET bottle, 10 ppm of citral was added, and each flavor deterioration inhibitor prepared in Example 1 and Comparative Examples 1 to 14 was added so that its solid content was 5 ppm, followed by photodeterioration test.

[0153] A sugar-acid solution containing citral prepared in the above formulation without adding a fragrance deterioration inhibitor was similarly irradiated with a fluorescent lamp (blank). A sugar-acid solution containing citral and no flavor deterioration inhibitor which was not irradiated with a fluorescent lamp was used as a control (untreated).

[0154] (light degradation test)

[0155] A test object filled with a test article in a transparent PET bottle was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com