A high speed magnetic suspension superimposition rail beam connection mechanism, a rail beam and a manufacturing method thereof

A technology of connection mechanism and manufacturing method, applied in the field of connection mechanism of superimposed track beams, to achieve the effects of convenient processing, cost reduction and scale reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

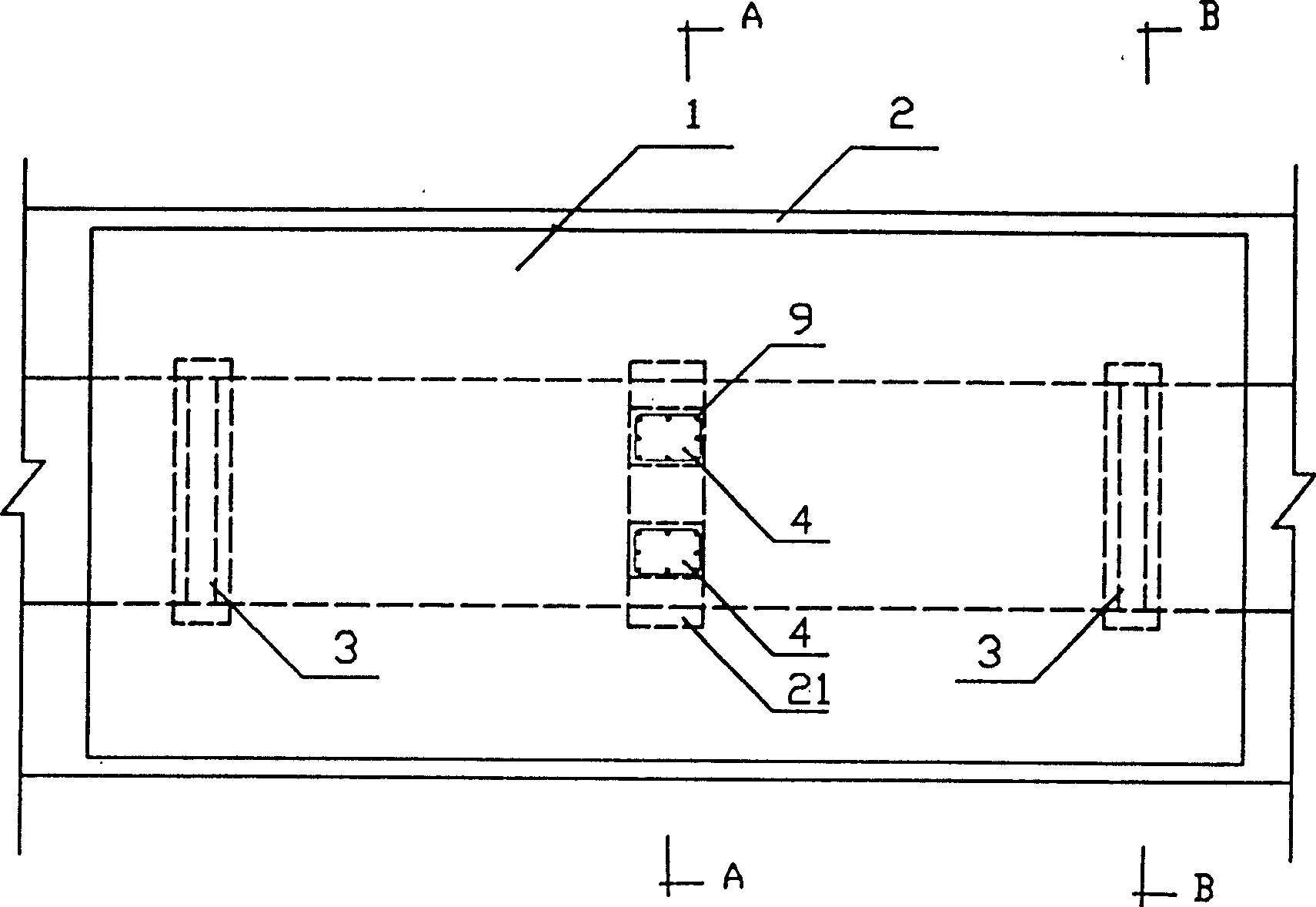

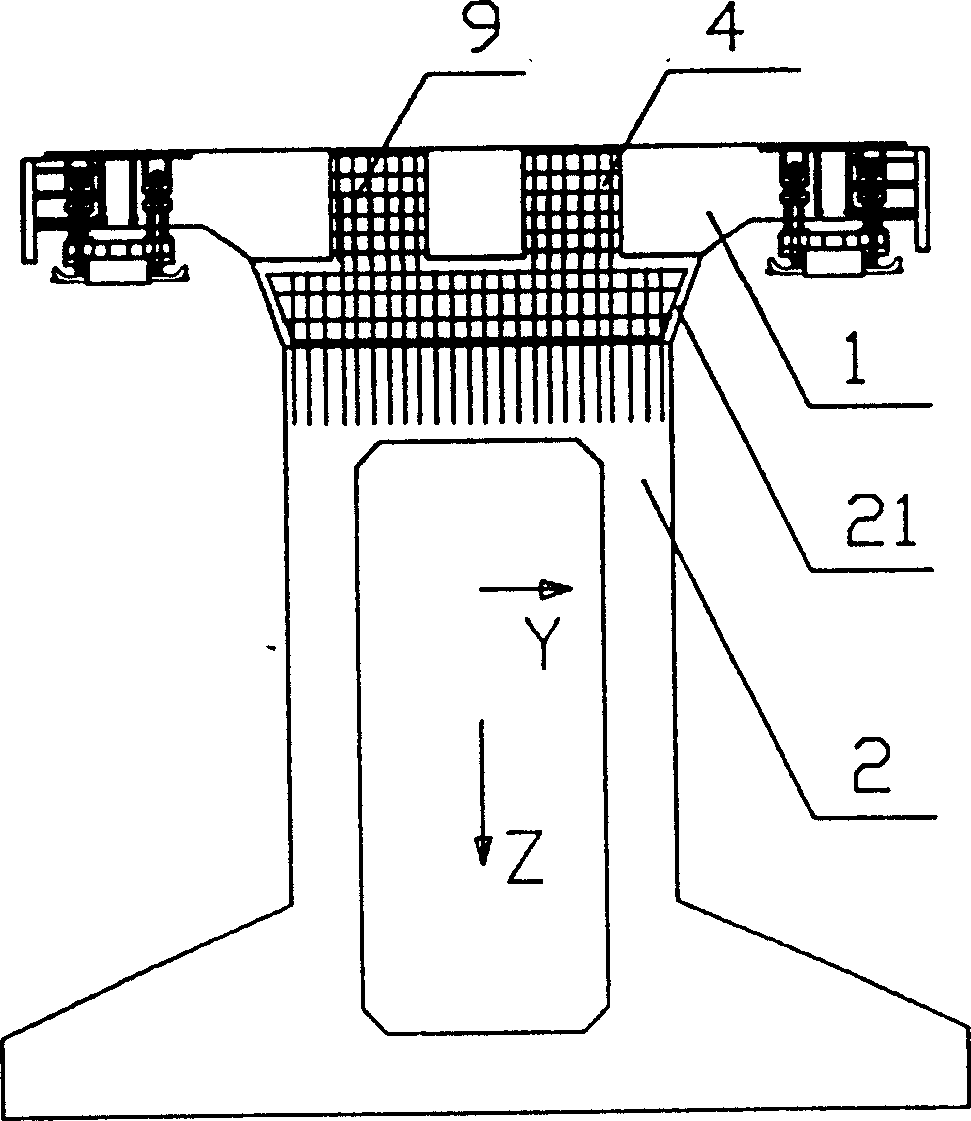

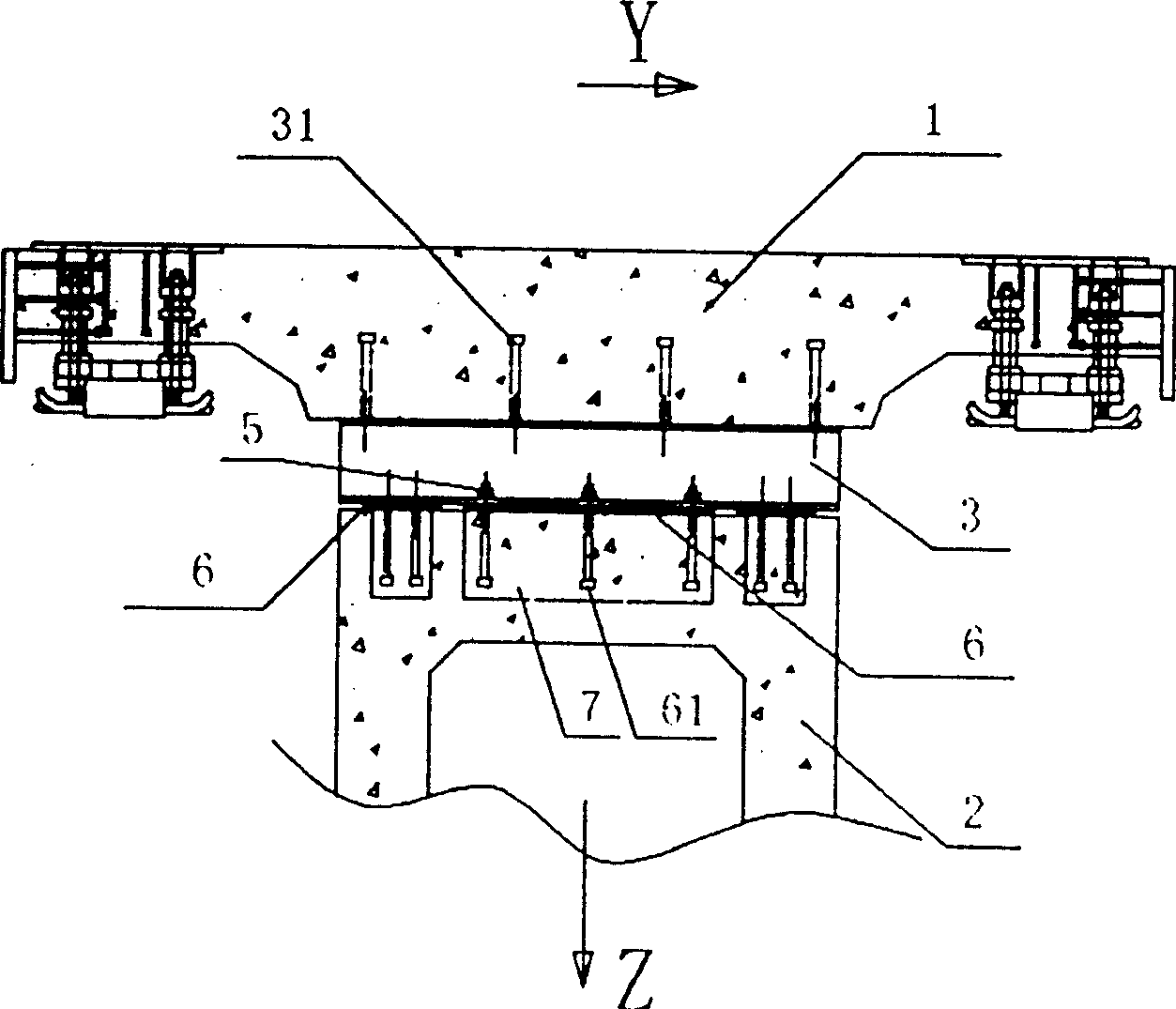

[0037] see Figure 1~3As shown, the present invention consists of two parts, the reinforced concrete grouting fixing part 4 which is located in the middle part of the track slab 1 and is connected to the load-bearing main beam 2, and the supporting steel beam 3 supported between the track slab 1 and the load-bearing main beam 2. composition. Firstly, the steel bar 9 is preset on the boss 21 of the load-bearing main beam 2. When installing on site, the steel bar 9 is inserted into the hole reserved in the middle part of the track plate 1. After the precise positioning between the track plate and the load-bearing main value, Concrete is poured into the hole to solidify into the reinforced cement grouting fixed part 4, so that the middle part of the track slab 1 is rigidly connected with the load-bearing main beam 2. The reinforced concrete grouting fixing part 4 can be arranged along the entire length of the boss 21, and can also be symmetrically divided into several parts and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com