Wiring structure for coupling chip

A wiring structure and chip technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as unfavorable product miniaturization, affecting the design size of integrated circuit chips 15, increasing manufacturing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

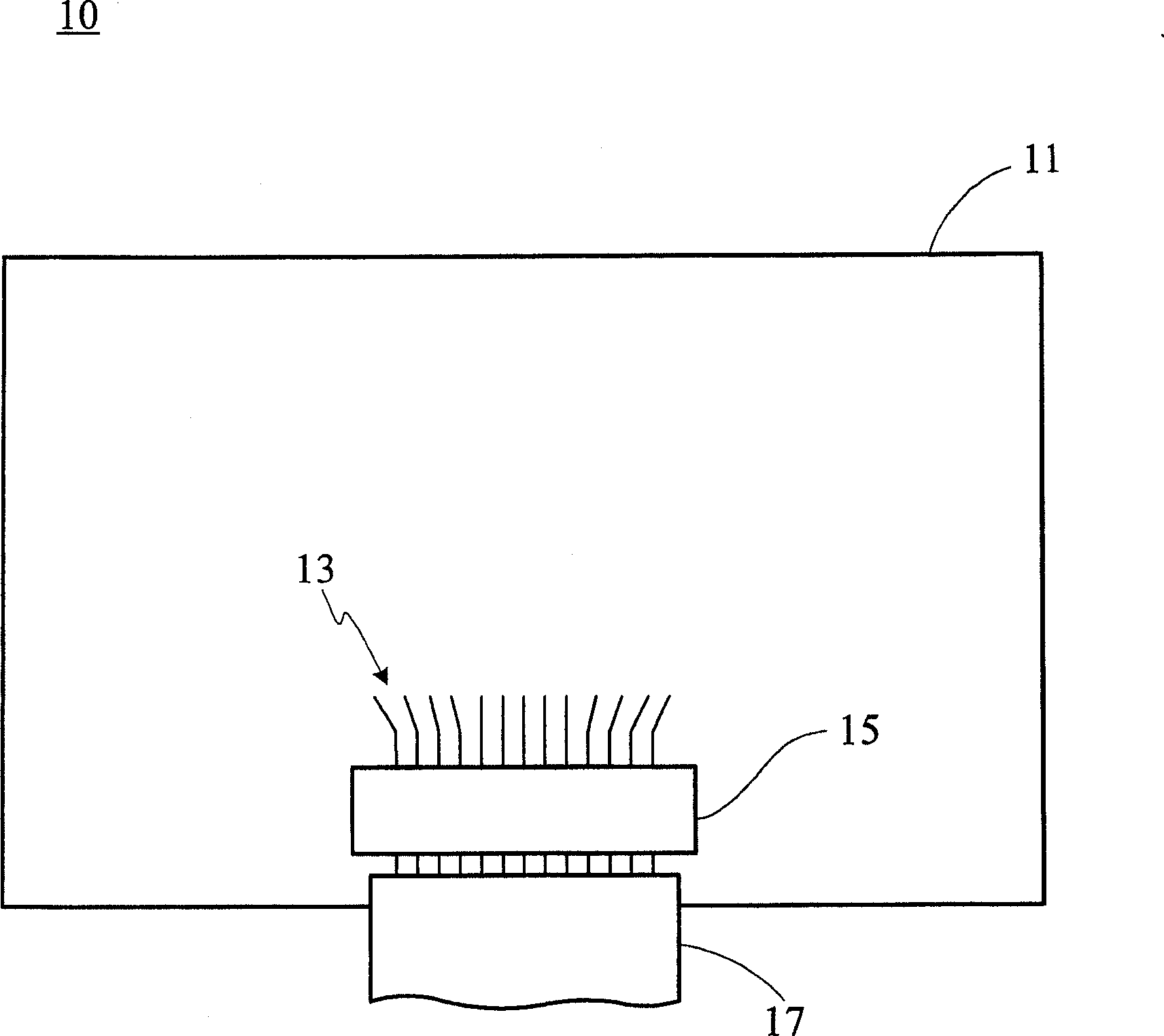

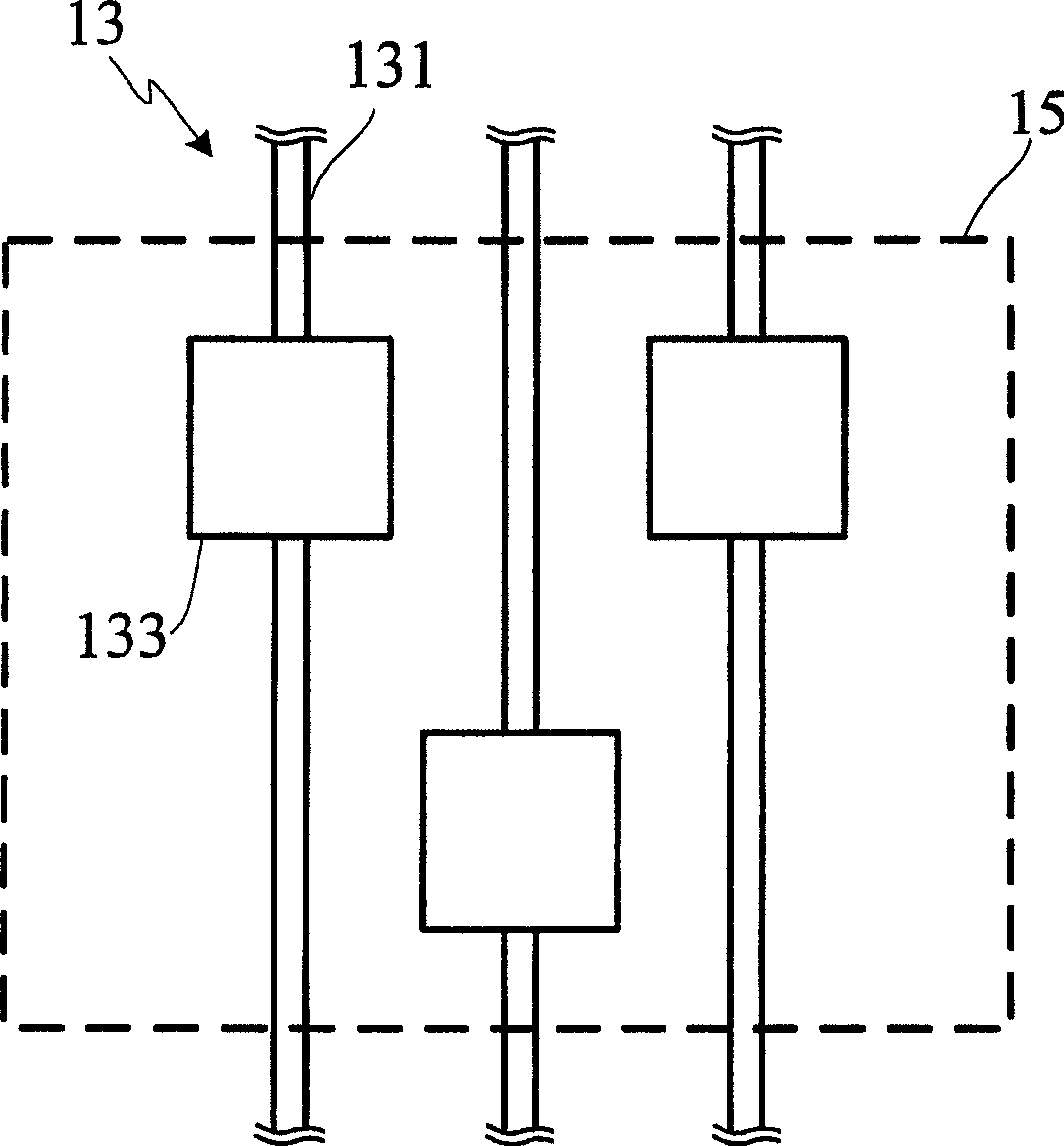

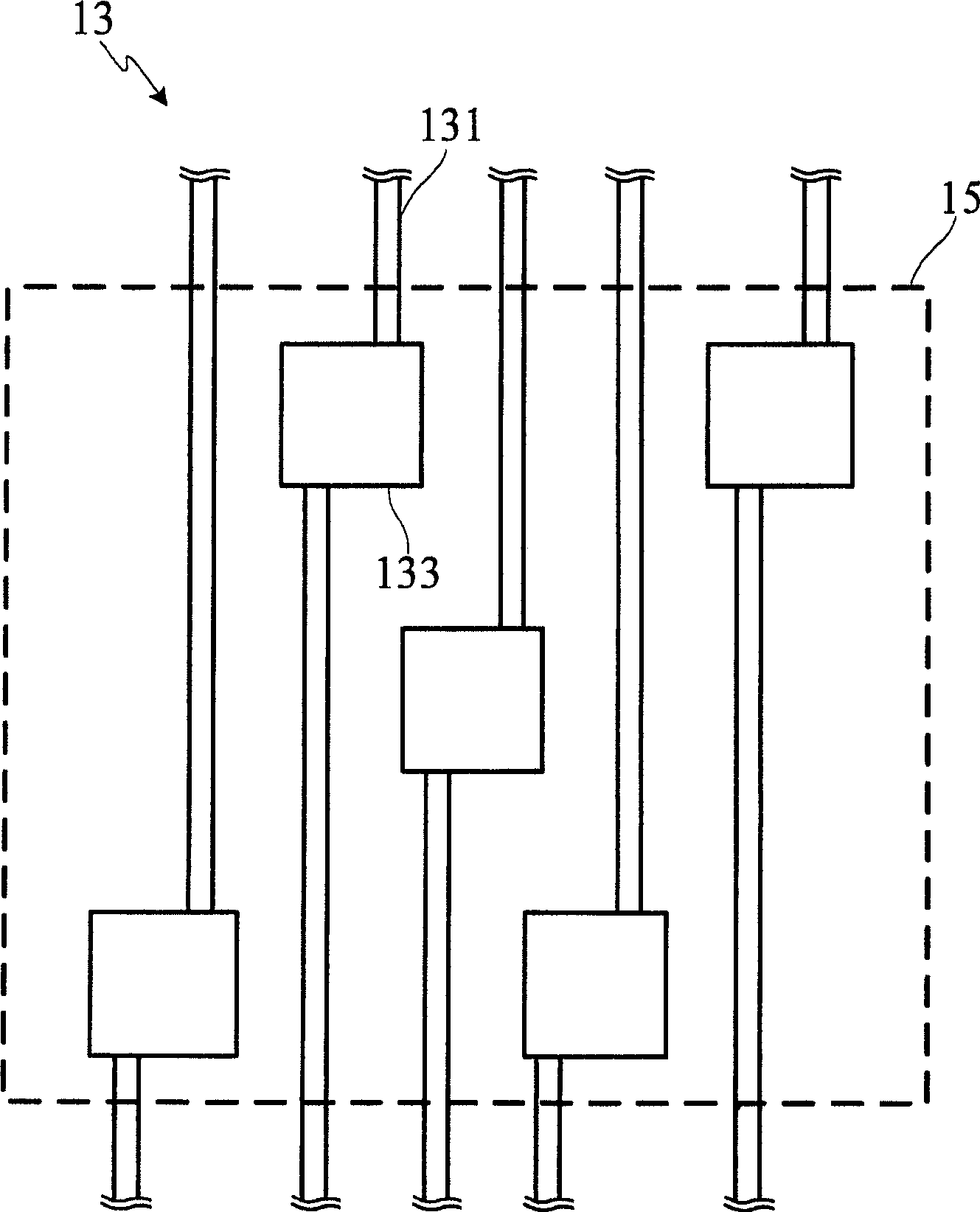

[0045] According to the present invention as image 3 In the preferred embodiment shown, the wiring structure 20 used in the present invention for coupling chips is arranged on the substrate of the liquid crystal display. For the convenience of illustration, a first direction X and a second direction Y that are substantially perpendicular to each other can be defined on the substrate. . The wiring structure 20 of the present invention includes at least one unit 30, and the unit 30 includes a plurality of lines and a plurality of conductive pads; Electrical conduction can be achieved after bonding.

[0046] Specifically, the plurality of lines includes a first line 41, a second line 42, and a third line 43, the lines are substantially parallel to each other and extend toward the second direction Y; and the plurality of conductive pads include a first conductive pad 51 . The second conductive pad 52 and the third conductive pad 53 are disposed on the first circuit 41 , the sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com