Refrigeration compressor

A technology for refrigeration compressors and compression pumps, which is applied in the control of mechanical energy, electromechanical devices, mechanical equipment, etc., can solve the problems of low power factor, large power grid impact force, large starting current, etc., and achieves the effect of simple and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] In this example, the refrigeration compressor uses a permanent magnet switched reluctance speed regulating motor as the driving device. The specific structure is as follows:

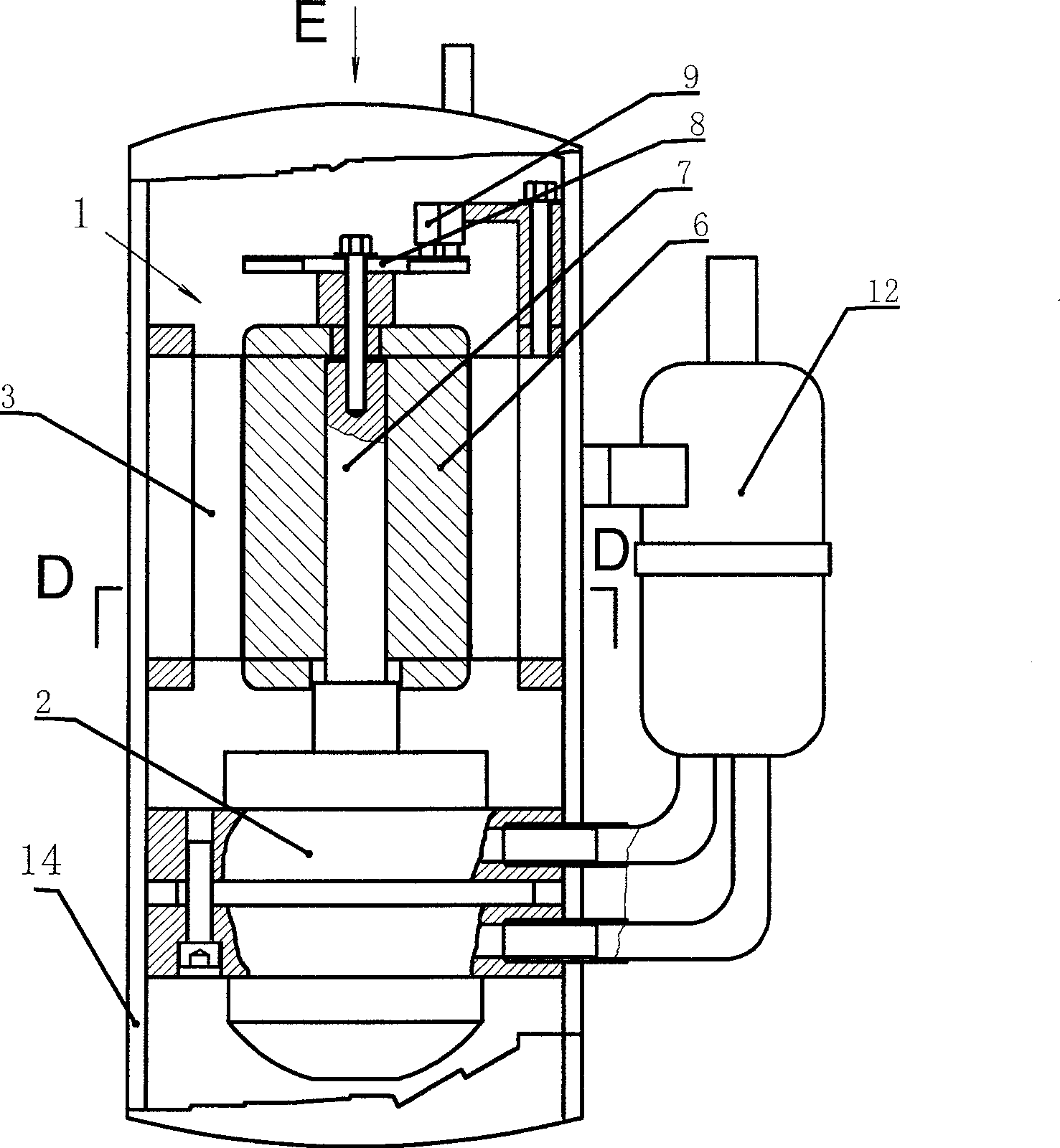

[0019] The casing 14 is a cylindrical pressure vessel made of A3 steel plate. A compression pump 2 is installed in the lower part of the inner cavity of the cylindrical casing. Liquid separator 12 is connected.

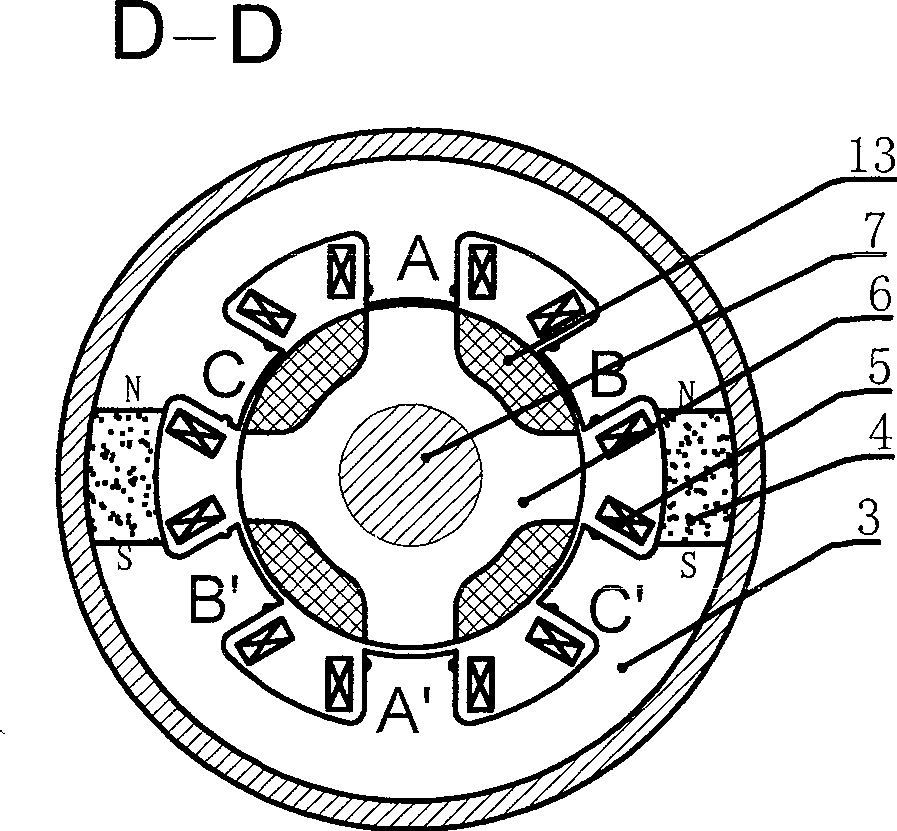

[0020] Motor 1 is a three-phase permanent magnet switched reluctance speed motor, see figure 2 , the stator 3 is made of laminated ordinary silicon steel sheets, and is provided with 6 inner salient poles, and the salient poles are equipped with driving windings 5 wound with enameled wires, and the connection methods are A-A', BB', C- C' symmetrical connection, series connection or parallel connection, two pieces of permanent magnets with high magnetic energy product and linear demagnetization curve made of rare earth NdFeB permanent magnet mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com