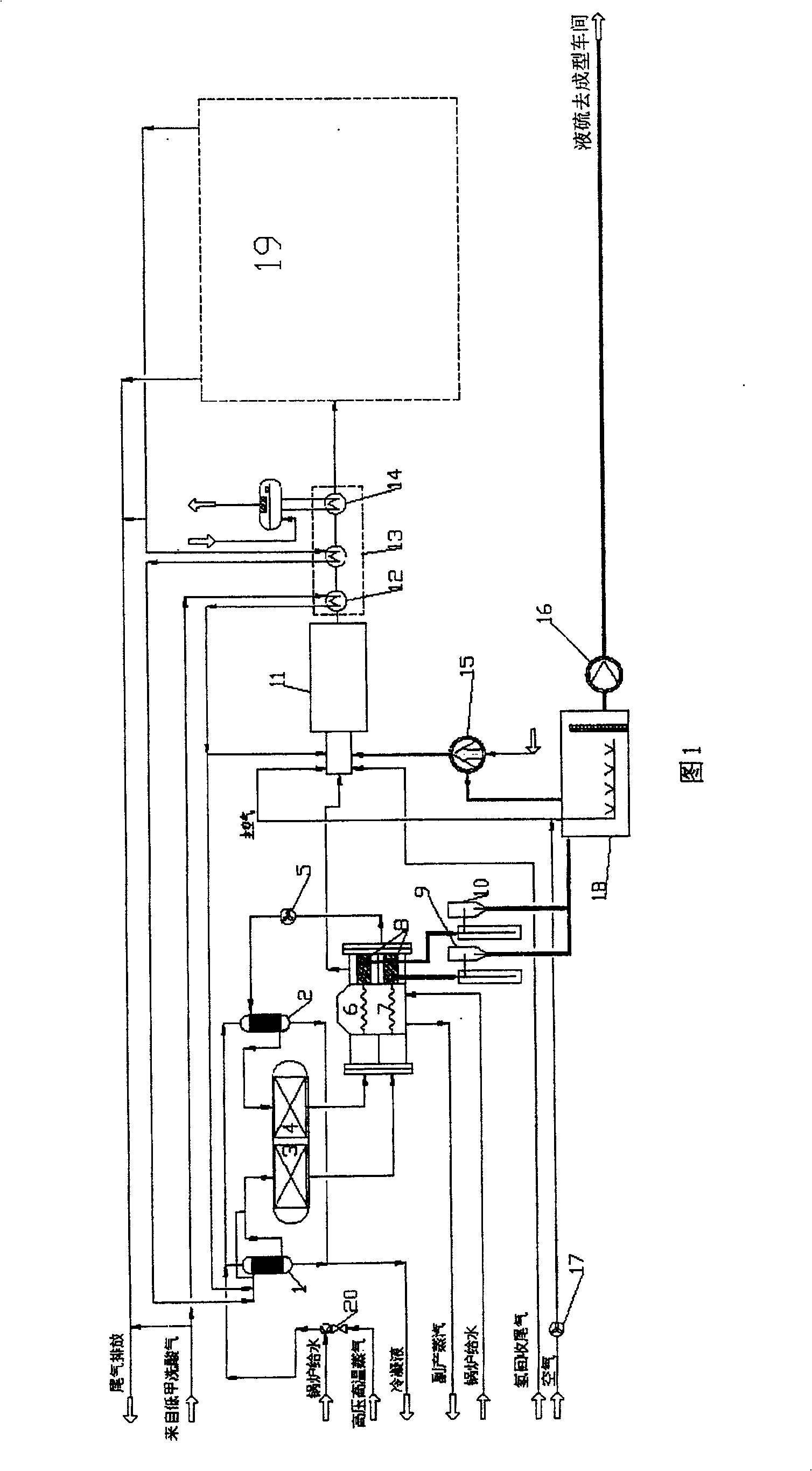

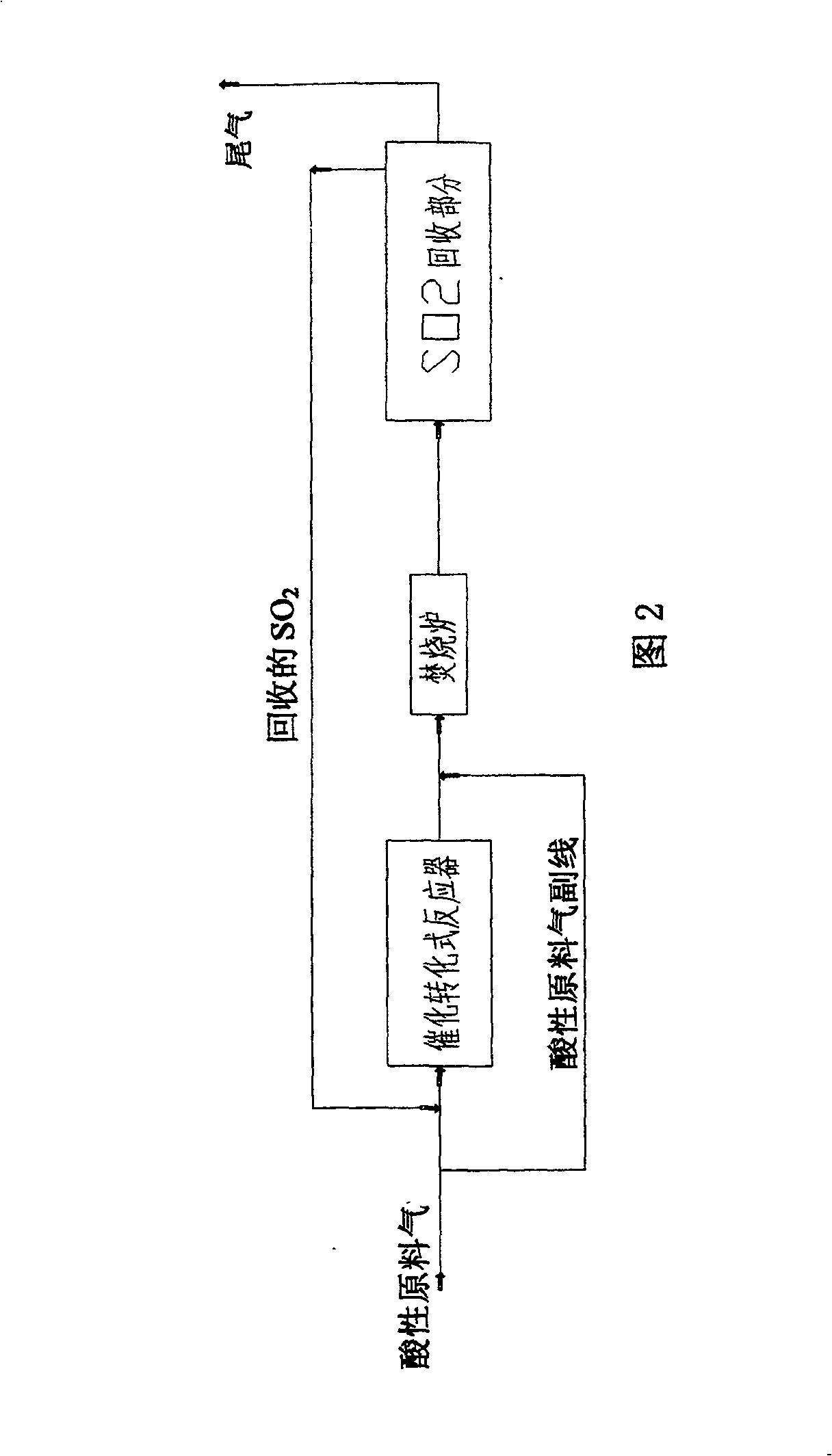

Device for the recovery and diffluence of sulfur dioxide and the system and method thereof

A sulfur dioxide and system device technology, which is applied in separation methods, chemical instruments and methods, sulfur preparation/purification, etc., can solve the problems of high operating costs and high prices, and achieve the effects of reduced investment, reduced consumption, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

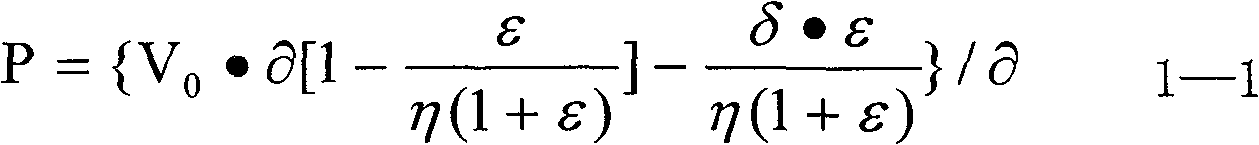

[0078] In a certain factory, the molar flow rate of acid feed gas is—V 0 =205.36kmol / h, H in acid feed gas 2 The molar fraction of S is 25.16%, the total COS, CS in the acid feed gas 2 Other organic sulfur (as elemental sulfur S 1 Meter) molar flow rate is——δ=1.00kmol / h, enters the H in the first stage Claus reactor 3 2 S and SO 2 The molar ratio is——ε=2.2, the sulfur recovery rate of the first and second stage Claus reactors 3,4 (in terms of elemental sulfur S 1 )——η=90%, then the system can additionally treat the maximum amount of sulfur-containing waste gas (in pure SO 2 Count) is:

[0079] δ 1MAX =205.36×0.2516×[0.9×(1+2.2)-2.2]÷2.2-1=14.97 kmol / h.

[0080] At this time, the amount of sulfur recovered has increased from the original 205.36×25.16÷100×32=1653 (kg / h) to 205.36×25.16÷100×32+14.97×32=2132 (kg / h), increasing production by 29%. The ability to treat waste gas is also improved accordingly, but the extent of the increase should be determined according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com