High-frequency soldering assembly for composite soft tube shoulder

A high-frequency welding and composite hose technology, which is applied in applications, household appliances, and other household appliances, can solve the problems of high power consumption of production line equipment, complex manufacturing process, and reduced heating efficiency, so as to improve the welding effect and optimize Improvement of production process and heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

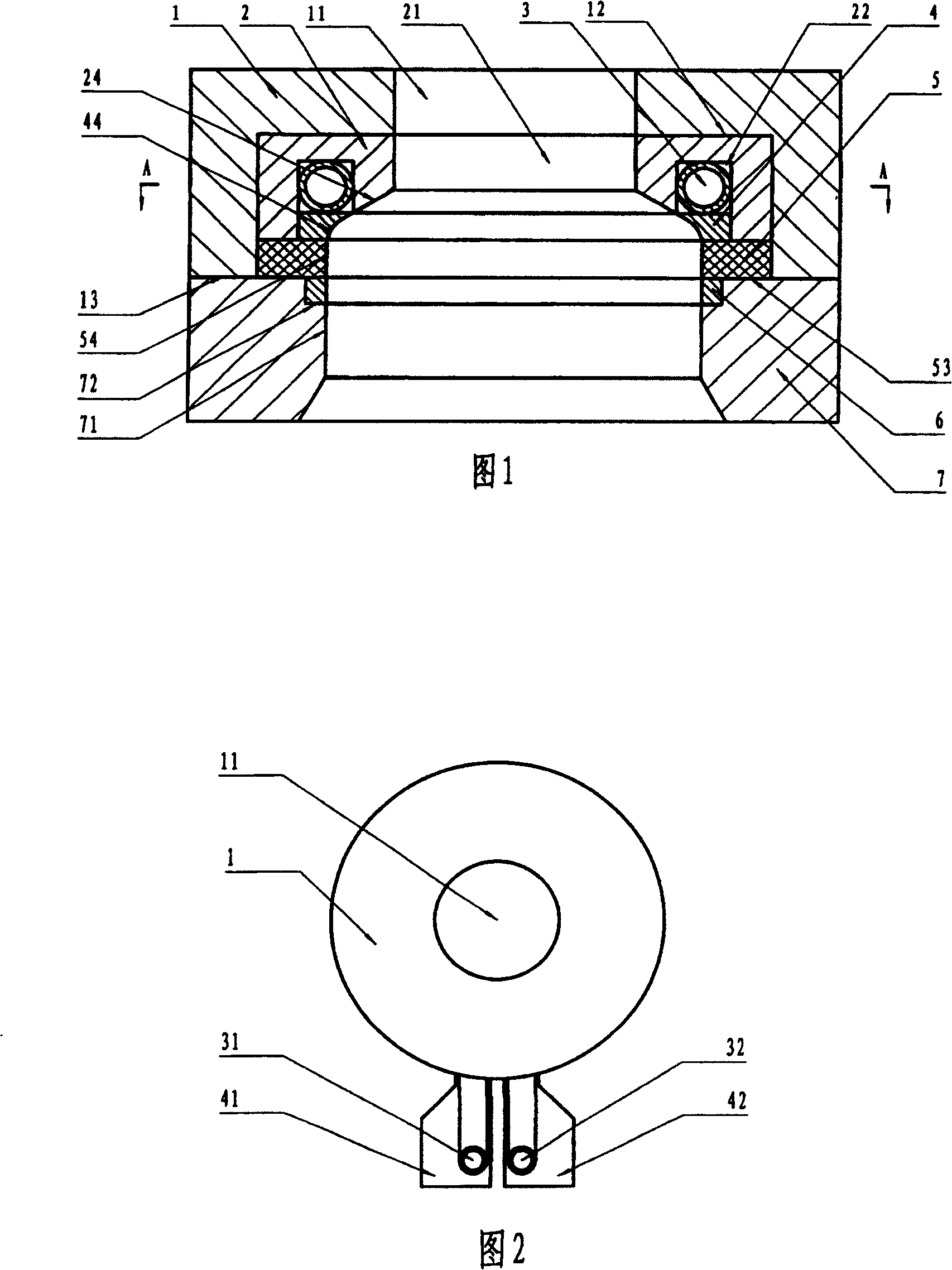

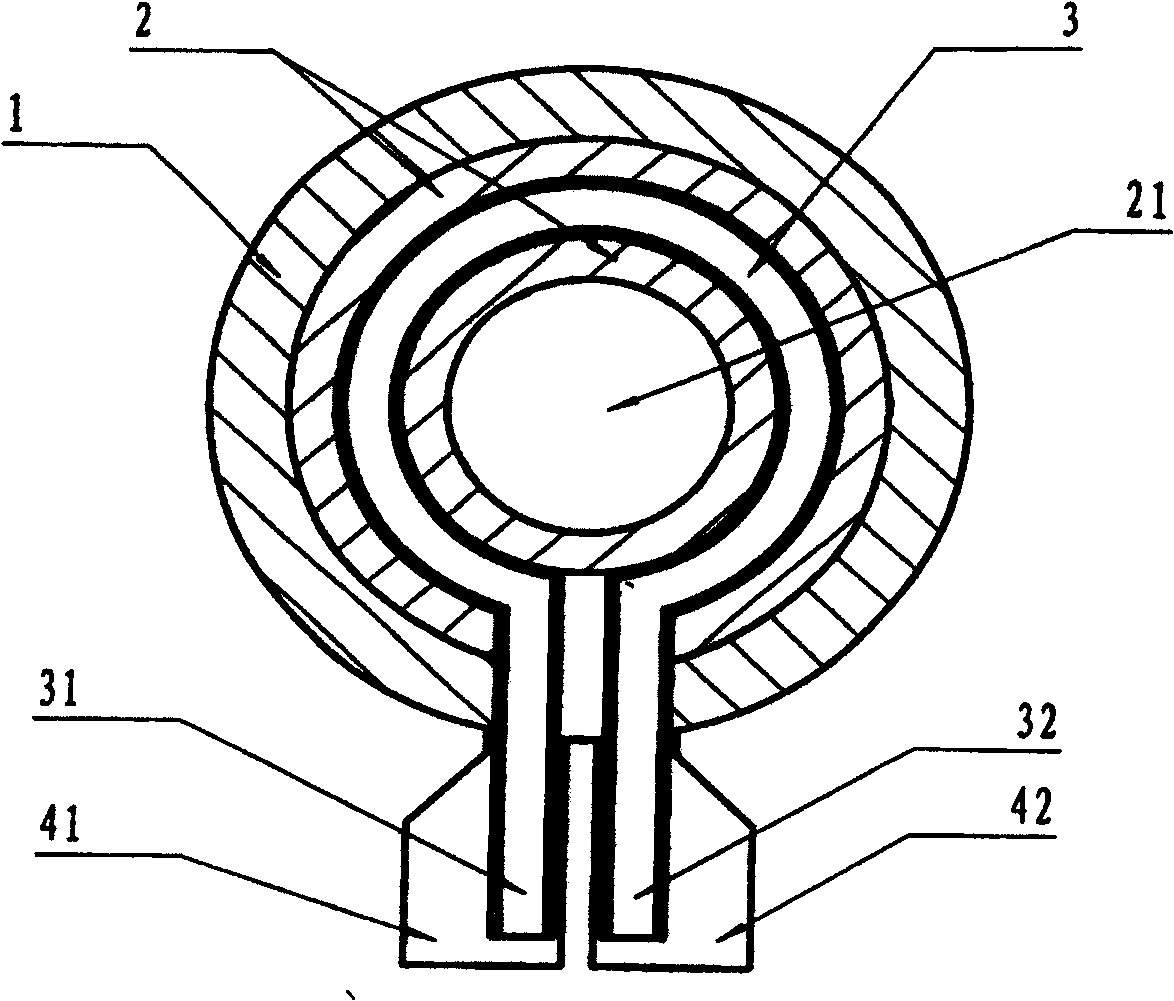

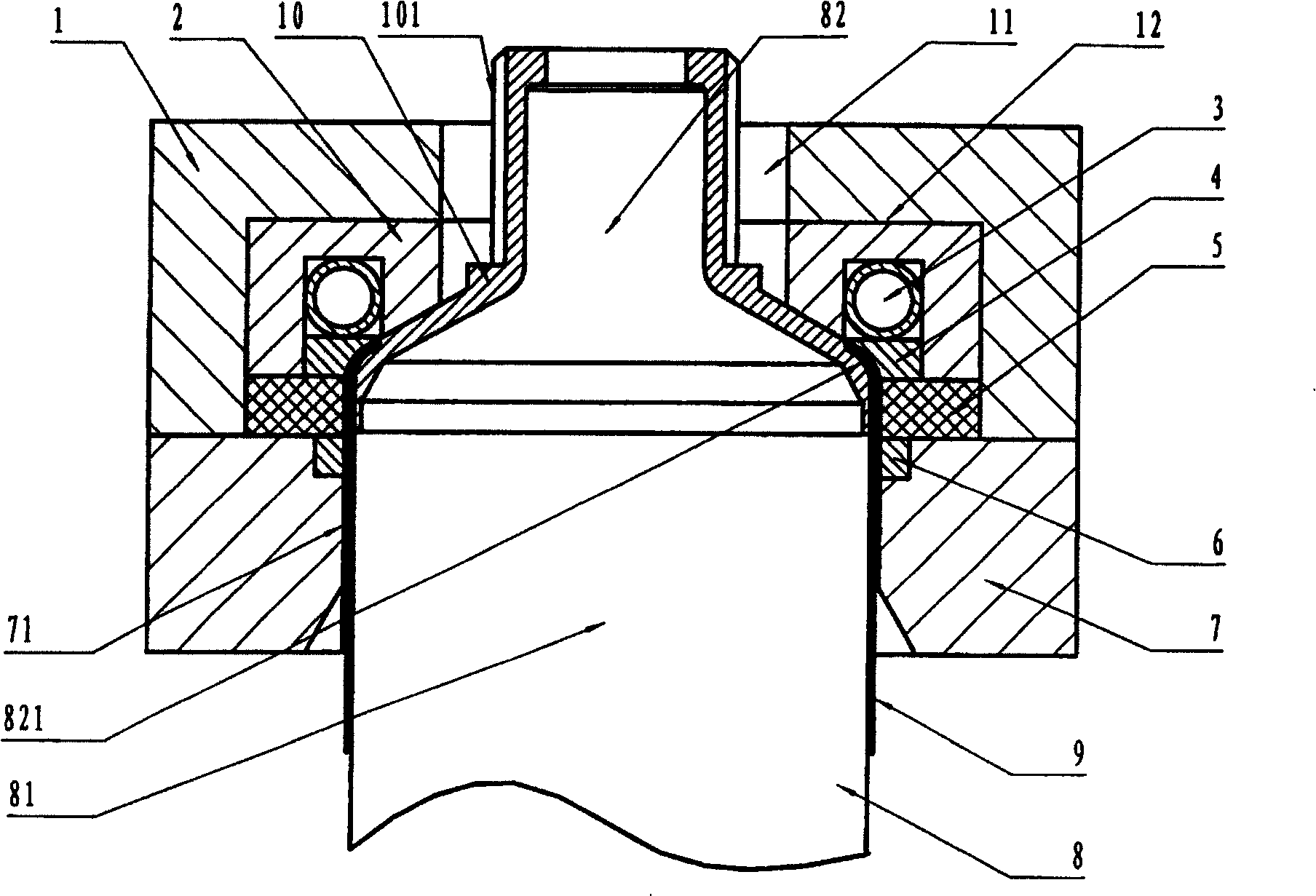

[0036] Please see Figure 1-3, a high-frequency welded assembly for composite hose shoulders,

[0037] A high-frequency welding head, including a seat body 1, wherein:

[0038] The base body is provided with a central hole 11 that can accommodate the protruding nozzle 101 of the hose shoulder 10. The base body 1 is left with a ring-shaped high-frequency magnetic material body 2 and a heat-resistant ceramic molding ring 5. the lumen 12;

[0039]The ring-shaped high-frequency magnetic material body 2 is embedded in the upper part of the inner cavity of the seat, and the inner hole 21 of the ring-shaped high-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com