Annular sealing gasket for liquid pump

A ring seal and ring seal technology, which is applied to liquid fuel engines, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as poor sealing at joints, gas-liquid leakage, and head shortening. Achieve the effect of simple and ingenious structure, increase air tightness and improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

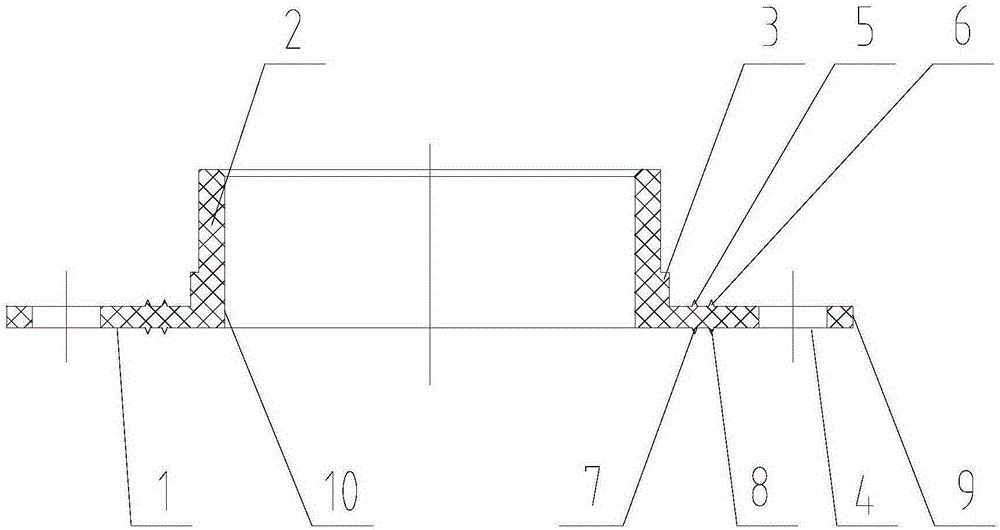

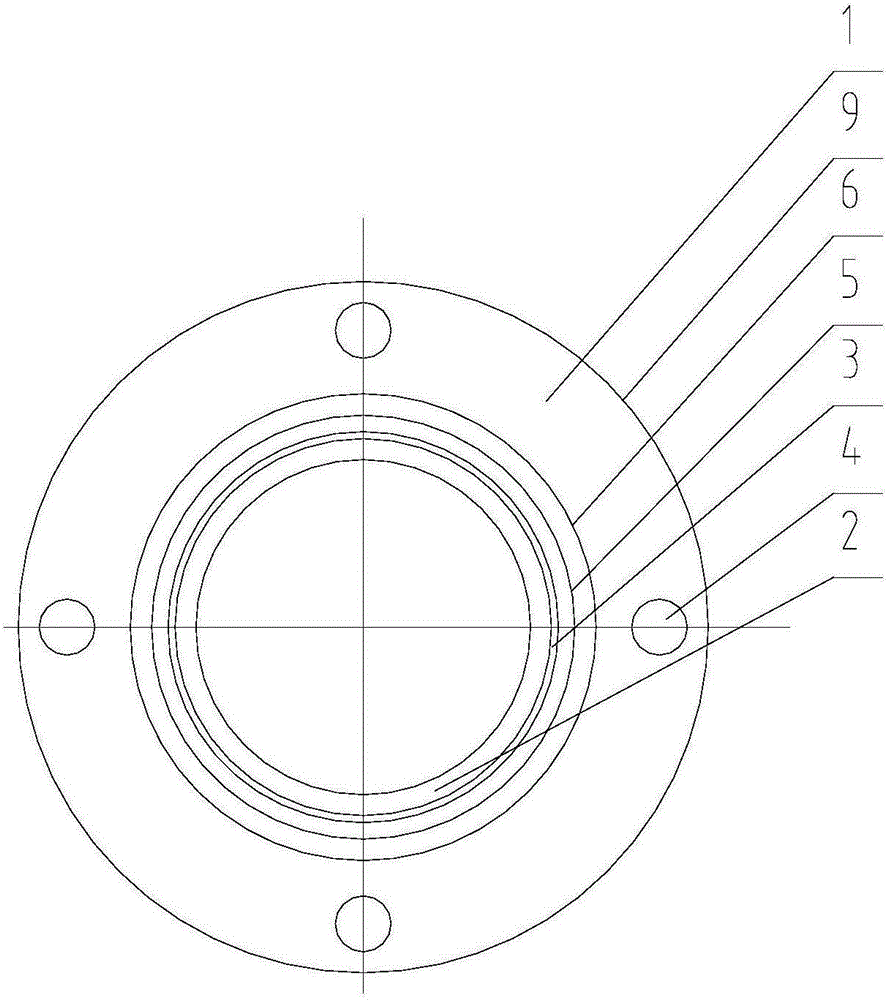

[0011] The main structure of the annular gasket for a liquid pump in this embodiment includes a gasket base 1, a cylinder 2, a boss 3, a bolt through hole 4, a first inner ring sealing line 5, a second inner ring sealing line 6, The first outer ring sealing line 7, the second outer ring sealing line 8, the outer circle 9 and the inner circle 10; the thickness of the gasket base 1 of the circular planar structure is 2-5mm, and the diameter of the outer circle 9 of the gasket base 1 1 to 3 times the diameter of the inner circle 10, the edge of the inner circle 10 of the gasket base 1 has an integrally formed cylinder 2 with a thickness of 2 to 5mm perpendicular to the gasket base 1, and the inner diameter of the cylinder 2 is the same as that of the gasket base. The diameter of the inner circle 10 of 1 is the same, and the height of the cylinder 2 is 10-50mm; on the end of the cylinder 2 close to the gasket base 1, there is an integrally formed boss 3 surrounding the circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com