Current lead of superconductive magnet

A technology of current leads and superconducting magnets, applied in superconducting magnets/coils, usage of superconducting elements, superconducting devices, etc., can solve the problems of increasing investment, insufficient cooling power of the primary cold head of refrigerators, complex system structure, etc. problem, achieve the effect of reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

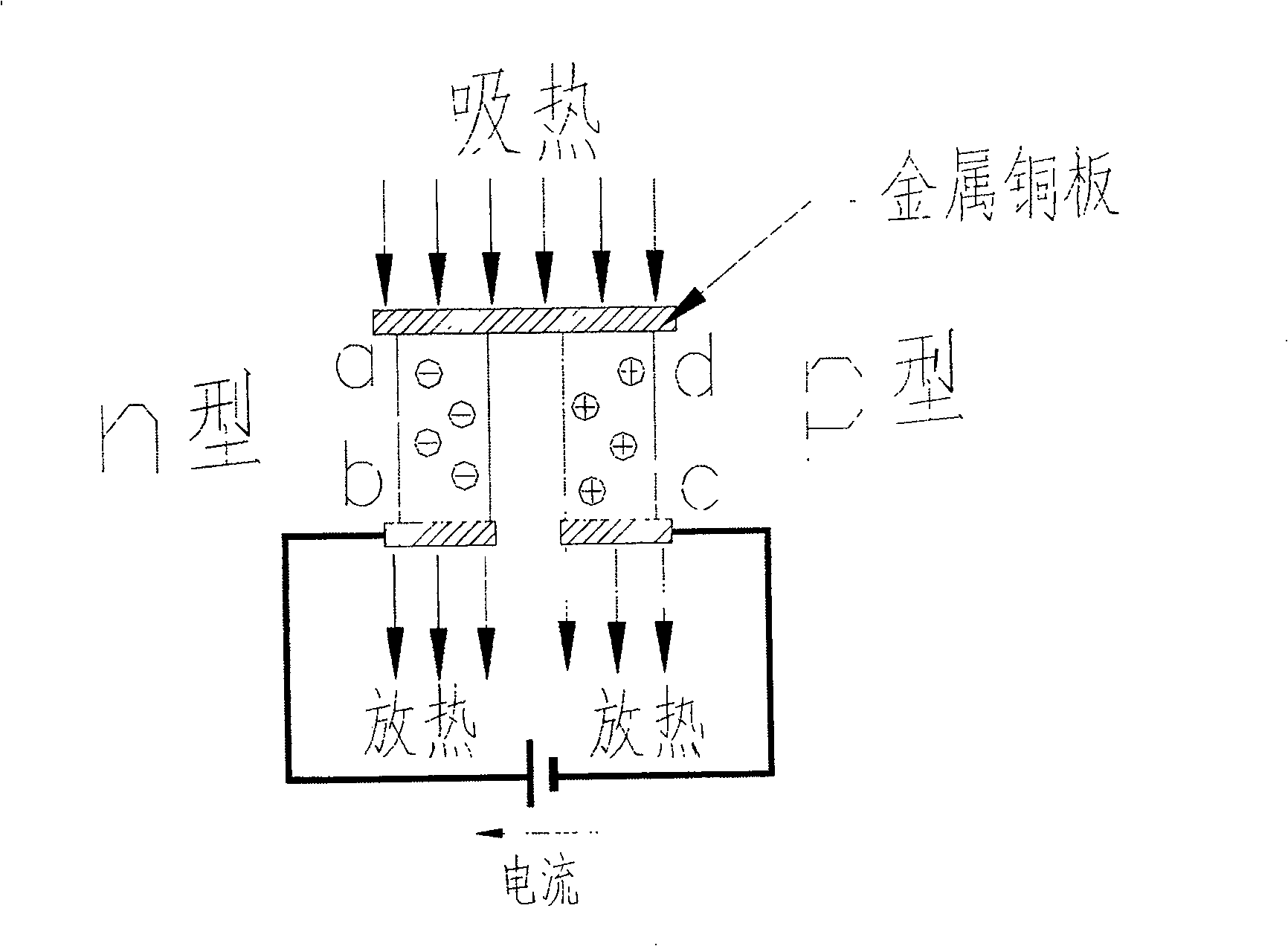

[0017] figure 1 Schematic diagram for the Peltier effect and thermoelectric refrigeration. When a piece of N-type semiconductor material and a piece of P-type semiconductor material are connected into a thermoelectric pair, after a direct current is connected in this circuit, energy transfer can occur, and the current flows from the N-type element to the joint of the P-type element to absorb heat. It becomes the cold end; the joint that flows from the P-type element to the N-type element releases heat and becomes the hot end.

[0018] Introducing a third material into the thermoelectric refrigeration circuit will not change the circuit properties, so copper current leads, high-temperature superconducting current leads and superconducting magnets can be connected in series in the thermoelectric refrigeration circuit.

[0019] The relationship betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com