Capacitor with nona-composite dielectric medium structure and method for manufacturing the same

A nanocomposite, dielectric technology, applied in capacitors, semiconductor/solid-state device manufacturing, nanotechnology, etc., can solve problems such as difficulty in ensuring high dielectric constant HfAlO nanocomposite dielectric layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, a capacitor having a nanocomposite dielectric structure and a method of manufacturing the same according to exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

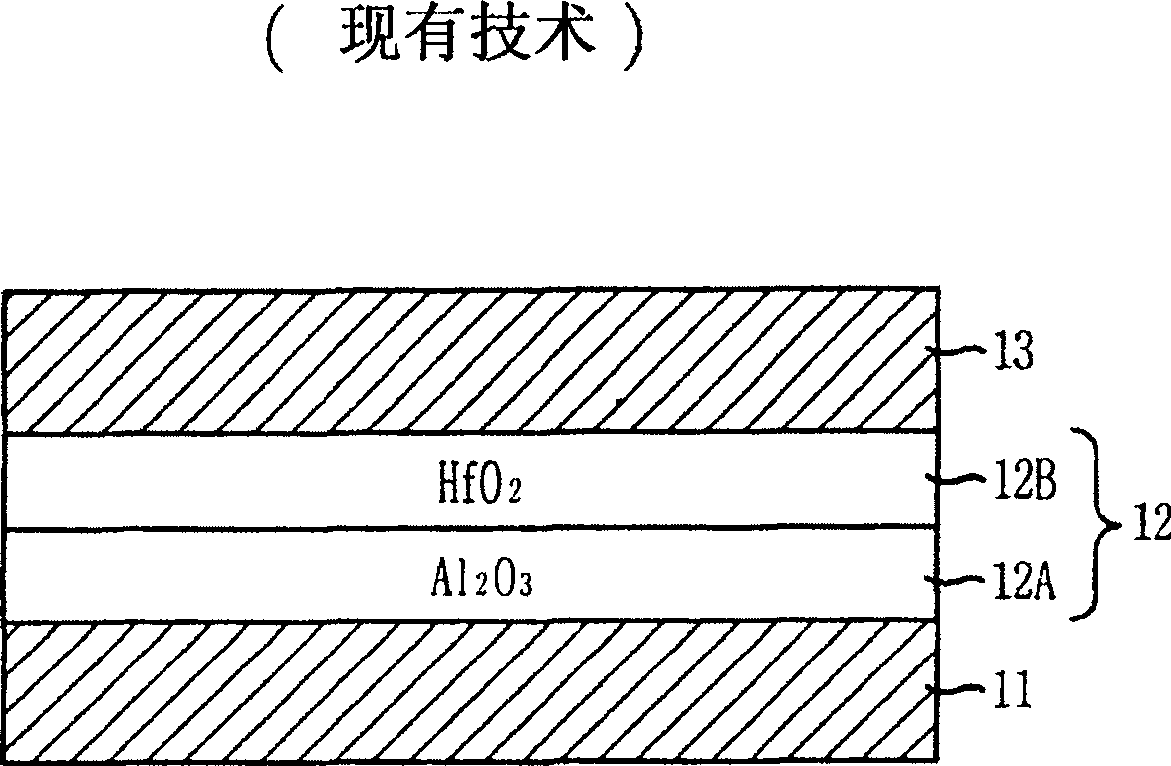

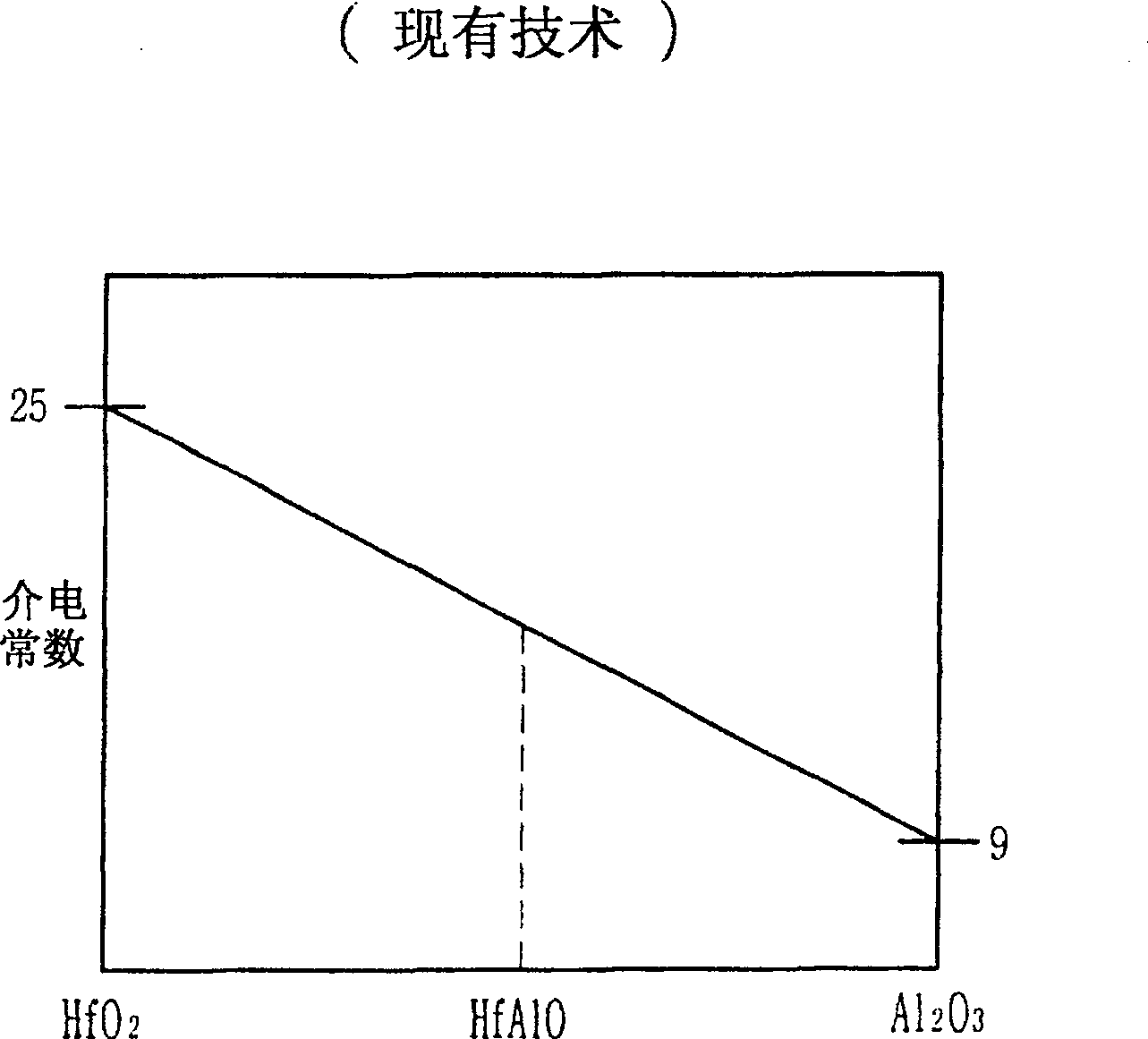

[0032] Exemplary embodiments of the present invention propose a dielectric structure with Al 2 o 3The same good leakage current characteristics can guarantee greater than about 20, close to HfO 2 The high dielectric constant of the dielectric constant, and can be applied to various types of capacitors. These advantages make it possible to apply the dielectric layer to highly integrated semiconductor devices having dimensions smaller than about 70 nm.

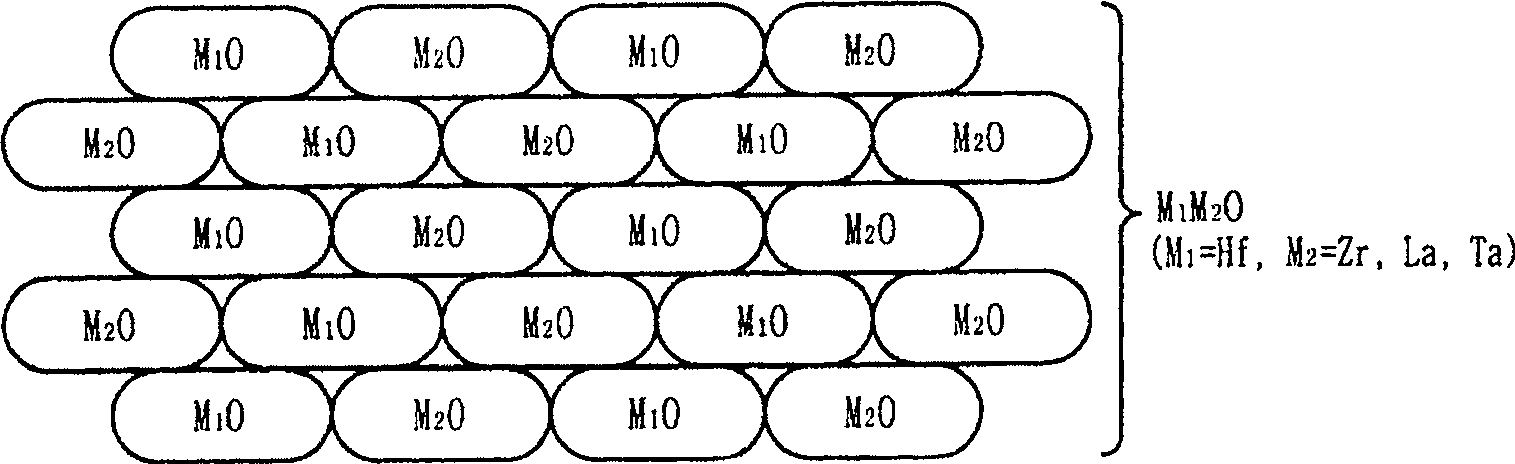

[0033] image 3 is a diagram depicting the concept of a nanocomposite dielectric structure according to an embodiment of the present invention. According to a specific embodiment of the present invention, the nanocomposite dielectric structure is not a simple stacked structure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com