Amplified solid-state image pickup device

A solid-state imaging device and pixel technology, which is applied in electric solid-state devices, semiconductor devices, image communication, etc., can solve problems such as the influence of afterimage characteristics, the inability to fully read signal charges, and the deterioration of signal linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

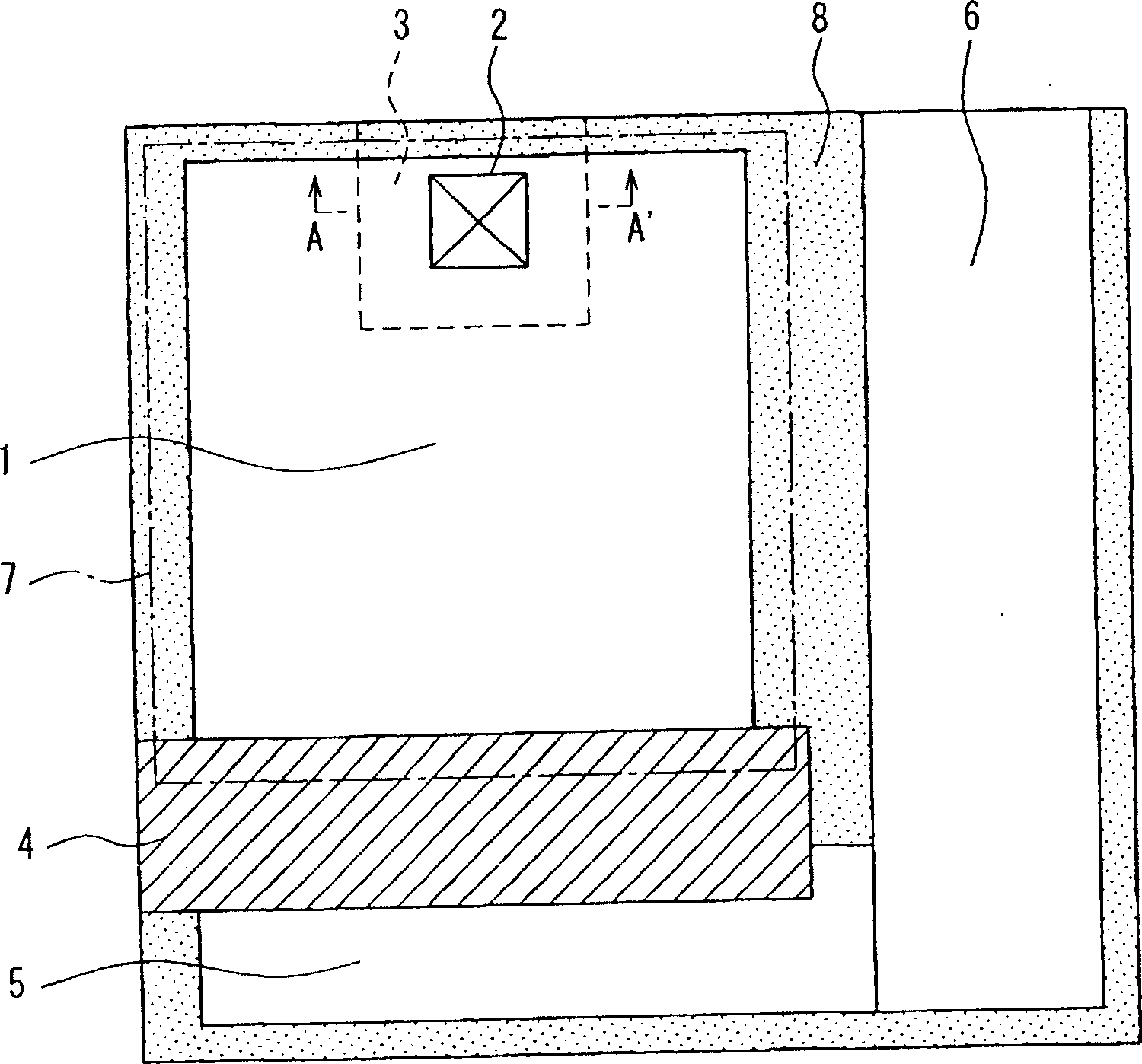

[0069] figure 1 is a schematic plan view showing a pixel portion of the amplified solid-state imaging device according to the first embodiment. The layout of this device is roughly divided into a photodiode section 1 , a floating diffusion capacitance section 5 , and a transistor arrangement section 6 . Transistors (not shown), such as reset transistors, drive transistors, and selection transistors, are arranged in the transistor arrangement unit 6 . A signal charge transfer gate 4 is provided between the photodiode unit 1 and the floating diffusion capacitor unit 5. 7 denotes a light-shielding aluminum opening. 8 indicates an inactive area.

[0070] The signal charge photoelectrically converted and stored in the photodiode unit 1 is transferred to the floating diffusion capacitor unit 5 through the signal charge transfer gate 4 . The signal charge is converted into a voltage by the floating diffusion capacitance section 5 , and amplified or impedance converted by the driv...

Embodiment approach 2

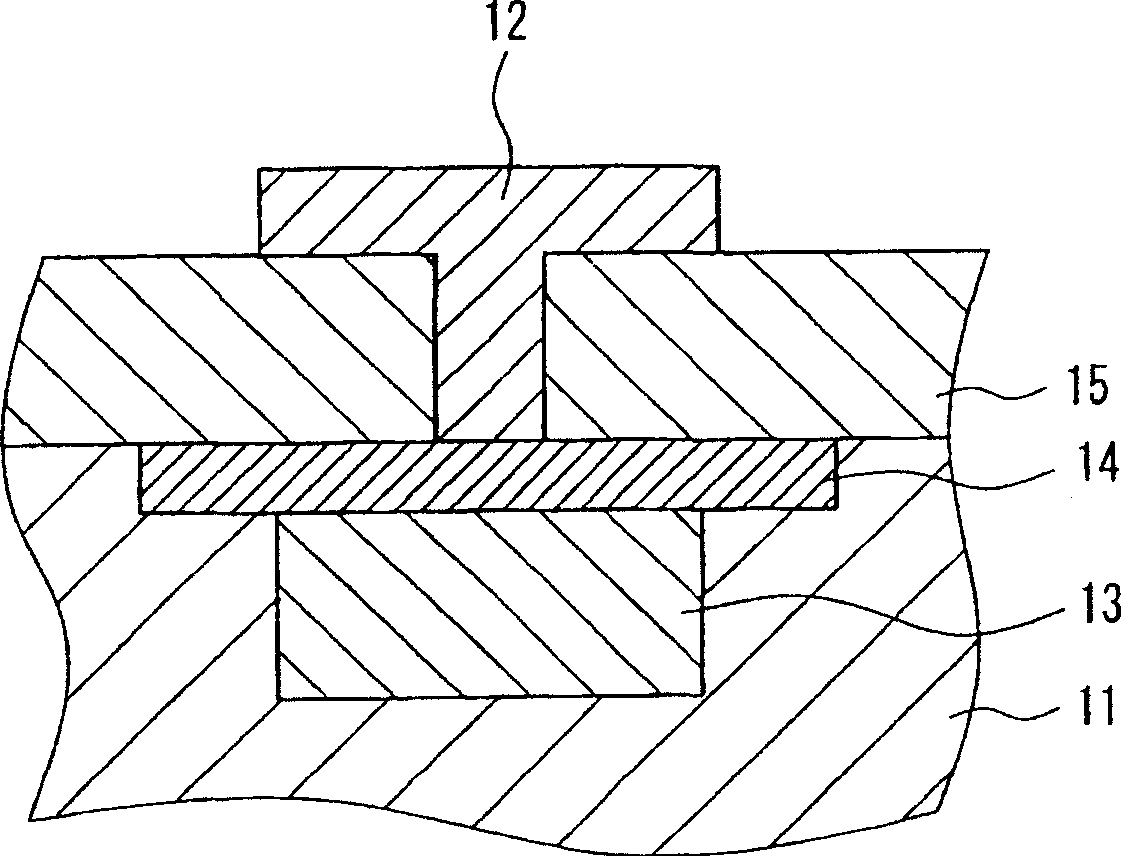

[0080] Constructed with reference to the cross-section representing the GND contact within the pixel figure 2 , the amplified solid-state imaging device of Embodiment 2 will be described.

[0081] A first conductivity type well region 13 and a first conductivity type surface layer 14 are formed in the second conductivity type photodiode injection region 11 . An in-pixel GND contact 12 is provided through an insulating layer 15 and is connected to the surface layer 14 of the first conductivity type.

[0082] The present embodiment is characterized in that the first conductivity type surface layer 14 is also used instead of the contact injection portion for the connection between the in-pixel GND contact 12 and the first conductivity type well region 13 . The impurity concentration of the first conductivity type surface layer 14 is set to 1.0×10 13 ~1.0×10 15 . Usually the first conductivity type injection area used in the contact injection part is set to 1.0×10 13 ~1.0×10...

Embodiment approach 3

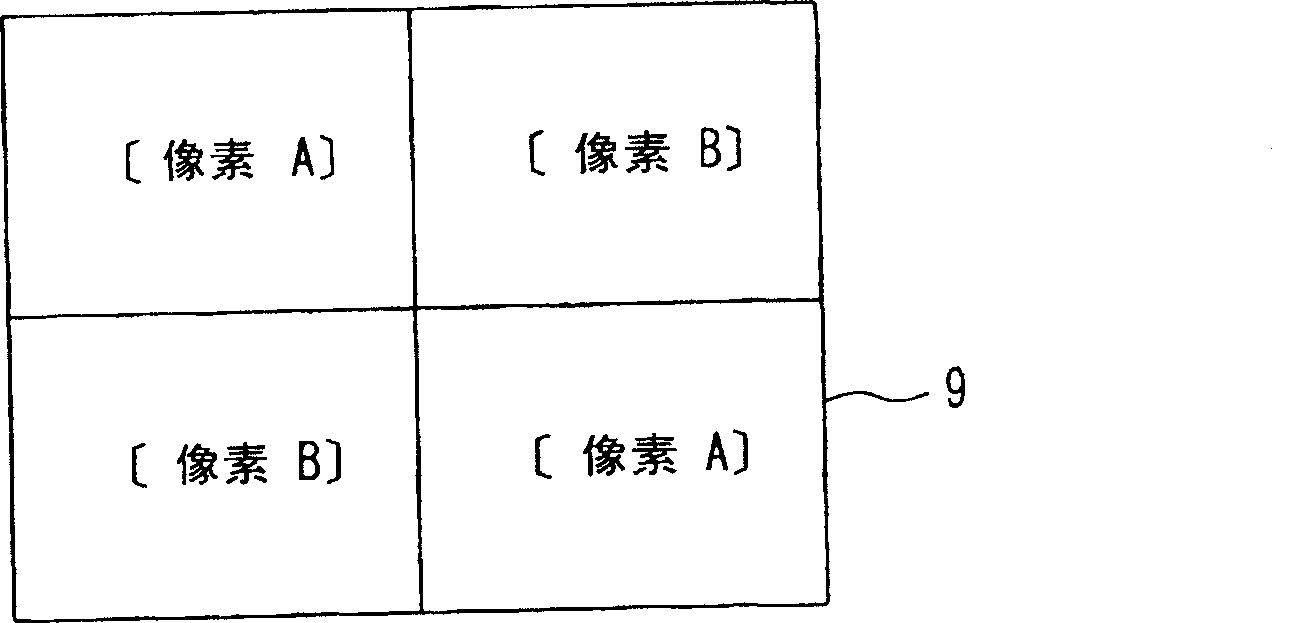

[0084] reference to the pixel layout Figure 3A-3C , the amplified solid-state imaging device of Embodiment 3 will be described. Figure 3A It is a plan view schematically showing an imaging area (only four pixels are shown) 9 . Should Figure 3B , 3C are floor plans representing the layout within pixels, respectively.

[0085] The present embodiment is characterized in that two or more types of pixels having different GND contact positions within the pixel are arranged in the imaging area 9 . That is, in the pixel A, the in-pixel GND contact 2 a and the first conductivity type well region 3 a are arranged on the upper right side of the photodiode 1 . In the pixel B, the in-pixel GND contact 2 b and the first conductivity type well region 3 b are arranged on the upper left side of the photodiode 1 . Such as Figure 3A As shown, pixels A are arranged on the upper left and lower right in the imaging area 9, and pixels B are arranged on the lower left and upper right.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com