Method for determining grid rigidity of lead acid battery and device therefor

A lead-acid battery and measuring device technology, applied in the direction of testing the hardness of materials, etc., can solve the problems of increasing the scrap rate of coated panels and production costs, and it is difficult to ensure the stability of the product production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The method of the invention is suitable for detecting the rigidity of lead-calcium alloy grids or lead-antimony alloy grids used in lead-acid storage batteries. The lead-calcium alloy grid or the lead-antimony alloy grid needs to be effectively hardened after casting. The hardening method can be hardened in a drying room: temperature: 60±10°C, time: 16-24h, or natural hardening for more than 1 week. The rigidity of the hardened grid is detected by the method of the present invention, qualified products enter the plate coating process, and unqualified products are subjected to effective hardening again.

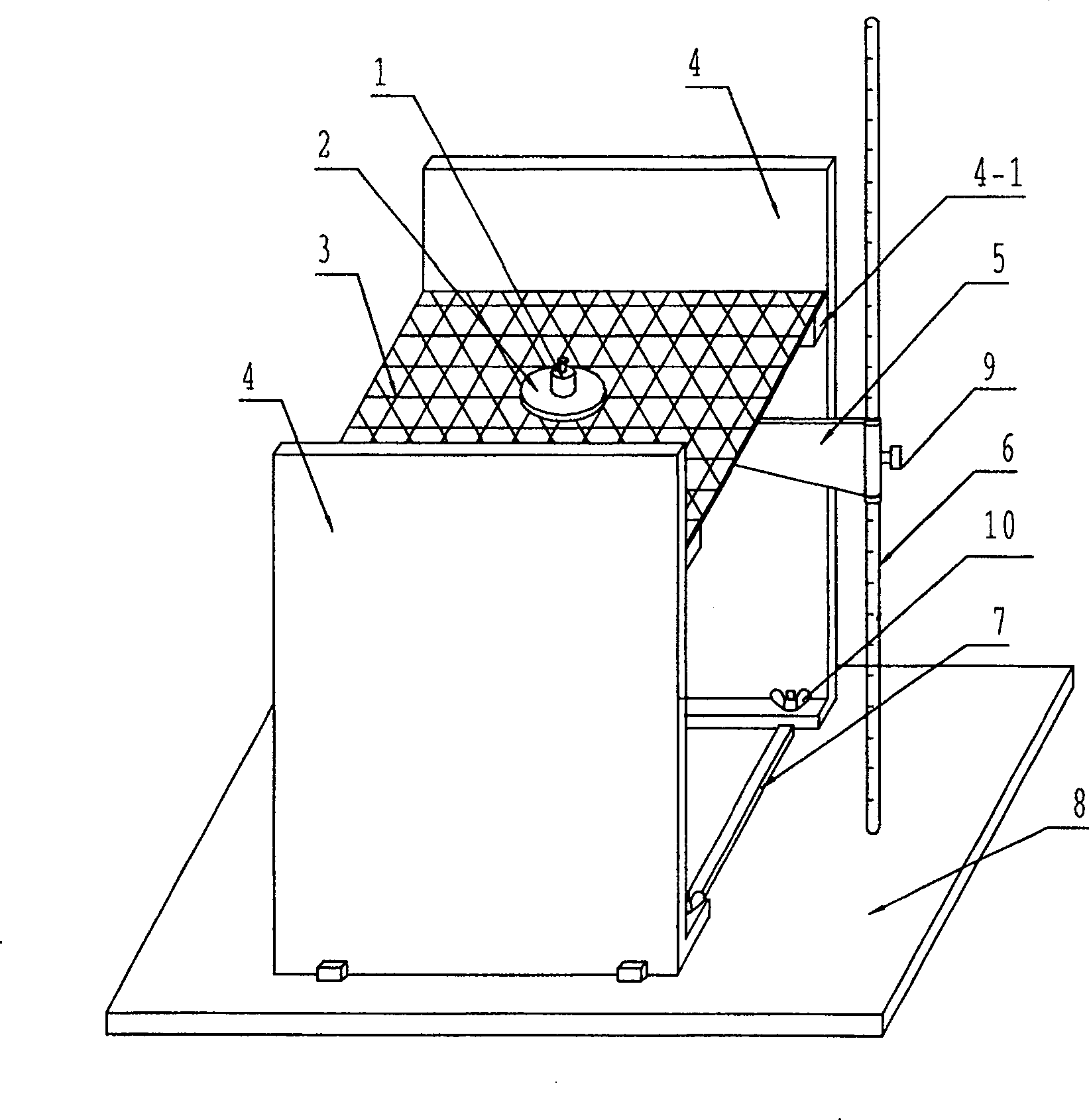

[0017] For the convenience of operation, the present invention designs a device for detecting grid stiffness. see figure 1 The device of the present invention comprises a base 8, a support frame 4, a scale 6, a measuring ruler 5 and a guide rail 7, the guide rail is fixed on the base, and the two support frames are positioned on the guide rails and can move along the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com