Light source structure

A technology of light source and fluorescent material, applied in the field of light source structure that can enhance luminous efficiency, can solve the problems of insufficient luminous efficiency, insufficient contact area between ultraviolet light and fluorescent material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

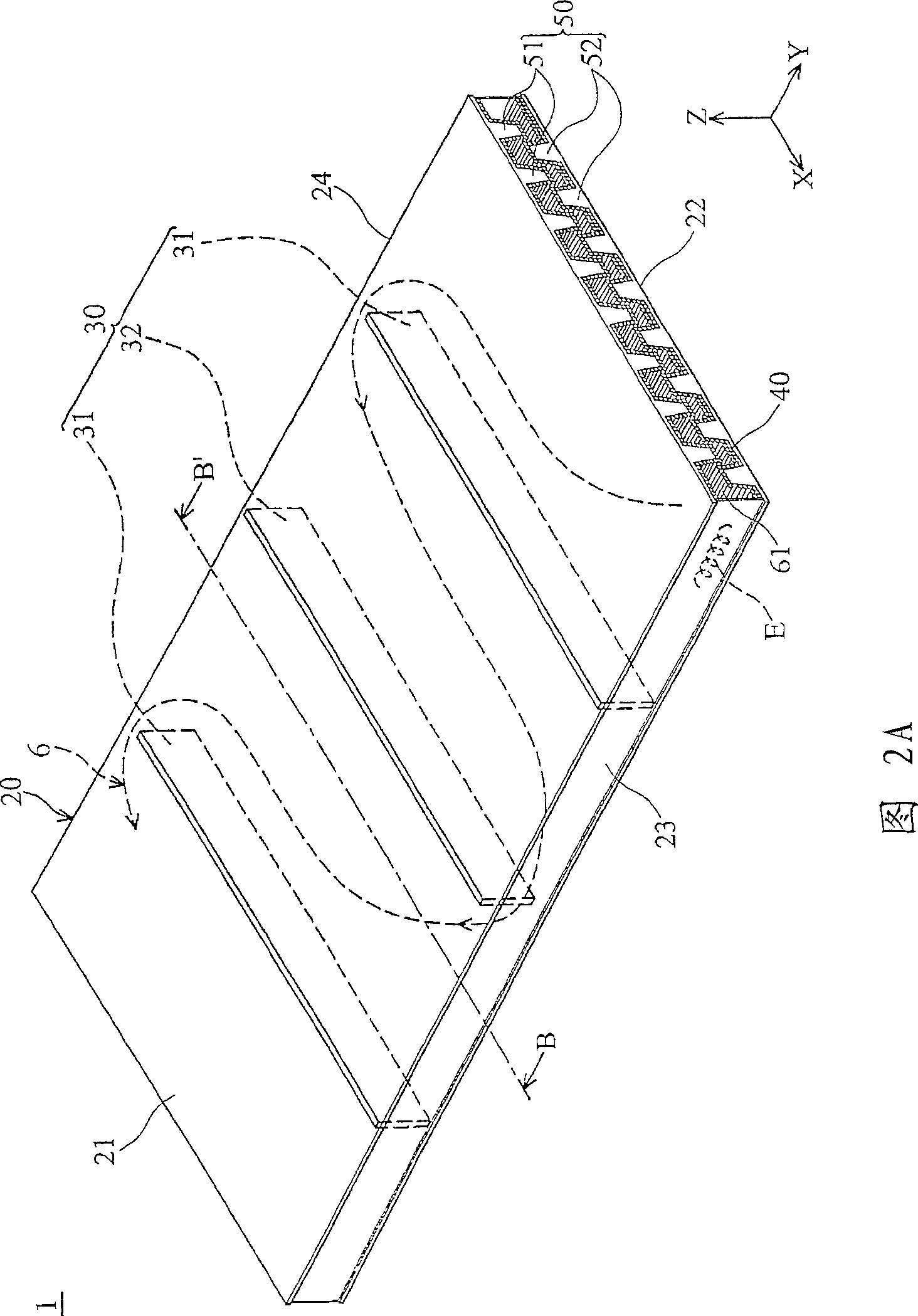

[0058] FIG. 2A is a partial perspective view showing the light source structure 1 according to the first embodiment of the present invention, and FIG. 2B is an exploded perspective view showing multiple curved channels 61 and 62 of the light source structure 1 according to the first embodiment of the present invention. Fig. 2C is a schematic cross-sectional view showing the light source structure 1 viewed along the section line BB' in Fig. 2A. It should be noted that only two curved channels 61 and 62 are marked in FIG. 2B as an example, and the number and length of the curved channels are not limited in the present invention.

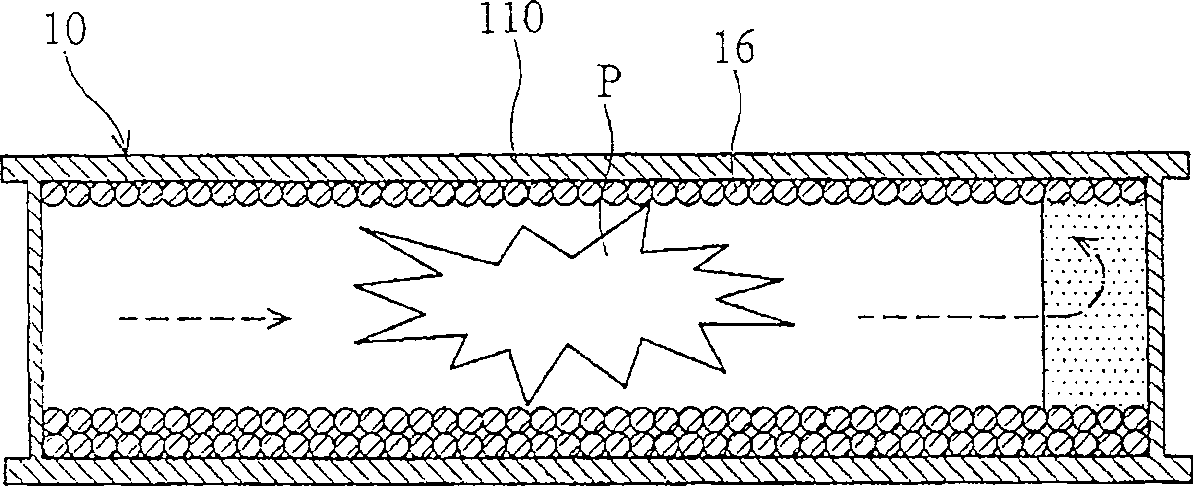

[0059] In this embodiment, as shown in FIGS. 2A and 2B , the light source structure 1 is placed on an XY plane, and the light source structure 1 is formed by a hollow shell 20 , positive and negative electrodes and a plurality of protrusions 50 . In order to simplify the illustration, FIG. 2A only shows one of the electrodes E, omitting to show the ele...

no. 2 example

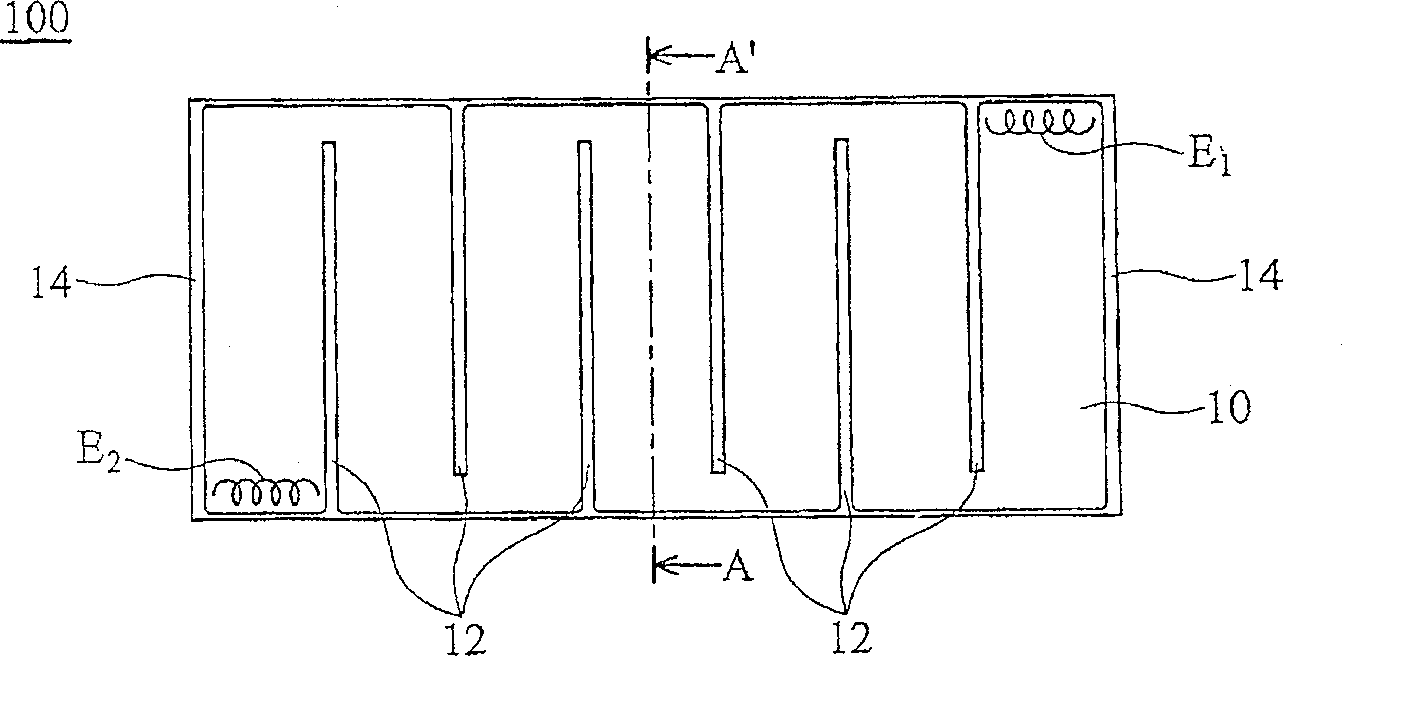

[0067] FIG. 3A is a schematic perspective view showing the light source structure 2 of the second embodiment. FIG. 3B is a schematic plan view showing the light source structure 2 of the second embodiment. FIG. 3C is a schematic cross-sectional view taken along line CC' in FIG. 3A. The light source structure 2 of the second embodiment is formed by a hollow casing 200 , positive or negative electrodes E and a plurality of protrusions 500 . The casing 200 includes a plurality of curved channels 610, a first plate 210, a second plate 220, a first side wall 230, a second side wall 240 and a plurality of partitions 300, and the fluorescent material 400 is arranged in the curved channel 610 the inner wall. The protrusion 500 includes a plurality of first protrusions 510 and second protrusions 520 . In this embodiment, the same parts as those in the first embodiment will not be repeated, but the difference is that: the first protrusion 510 is hollow, and the first protrusion is fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com