Flue gas denitration multiporous organic catalyst and its preparation and using method

A technology of organic catalyst and denitrification reactor, which is applied in the field of flue gas denitrification porous organic catalyst and its preparation and application. It can solve the problem of no humic acid organic porous catalyst and achieve good energy saving effect, good benefit and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

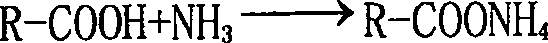

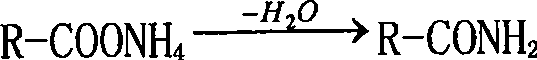

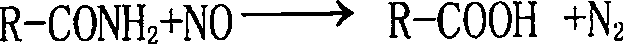

[0026] Take humic acid powder particles and TiO 2 , V 2 o 5 , polyurethane adhesive, and water, according to the mass ratio of 8:4:4:1:3, are stirred and mixed evenly in a high-speed mixer; then extruded into a honeycomb porous body through an extruder using a die. The extruded honeycomb porous catalyst was dried in an oven at 150° C. for 3 h to consolidate it. The prepared catalyst is placed in a horizontal monomer denitration reactor. by NH 3 The amount that completely reacts with R-COOH is sprayed on the denitrification porous organic catalyst. Into the industrial boiler flue gas. In the denitration reactor device, the controlled reaction temperature is maintained at 50°C. Steady-state removal of NO under this operating condition x , The removal rate is 85%.

Embodiment 2

[0028] Take humic acid powder particles and TiO 2 , V 2 o 5 , polyurethane adhesive, and water, according to the mass ratio of 80:2:2:1:5, are stirred and mixed evenly in a high-speed mixer; then extruded into a honeycomb porous body through an extruder using a die. The extruded honeycomb porous catalyst was dried in an oven at 150° C. for 3 h to consolidate it. Place the prepared catalyst in a horizontal monomer denitrification reactor, press NH 3 The amount that completely reacts with R-COOH is sprayed on the denitrification porous organic catalyst. Into the industrial boiler flue gas. In the denitrification reactor device, the controlled reaction temperature is maintained at 150°C. Steady-state removal of NO under this operating condition x , The removal rate is 90%.

Embodiment 3

[0030] Take humic acid powder particles and TiO 2 , V 2 o 5 , polyurethane adhesive, and water, according to the mass ratio of 18:4:4:1:3, are stirred and mixed evenly in a high-speed mixer; then extruded into a honeycomb porous body through an extruder using a die. The extruded honeycomb porous catalyst was dried in an oven at 150° C. for 9 h to make it solidified. Place the prepared catalyst in a horizontal monomer denitrification reactor, press NH 3 The amount that completely reacts with R-COOH is sprayed on the denitrification porous organic catalyst. Into the industrial boiler flue gas. In the denitration reactor device, the controlled reaction temperature is maintained at 250°C. Steady-state removal of NO under this operating condition x , The removal rate is 85%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com